- CAD Plotters

- Wide-Format Photo, Fine Art & Graphic Printers

- HP Latex, Outdoor, Signage, Wall Paper Printers & Cutters

- Wide Format Ink & Media Supplies

- Multi Functional Printers & Plan Copiers

- Large Format Scanners

- Finishing - Large Format Paper Folders, Trimmers, XY Cutters & Laminating

- Canon A4 and A3 Copier Paper

- Canvas, Stretcher Bars & Laminate

- Fabric Printers

- 3D Printers

- Autodesk Subscription & HP CAD Workstations

- Colour Management & RIP Software

- Plotter Warranties

- Storage & Filing Systems

- OFFERS

Why use plot-IT?

- Est since 1965

- Group turnover - £15 million

- 5 UK offices with over 100 staff

- HP Designjet Warranty Provider

- Autodesk Gold reseller

- Canon Elite Partner

- Stratasys - Gold Partner

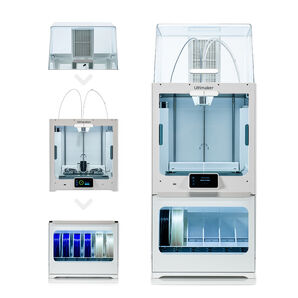

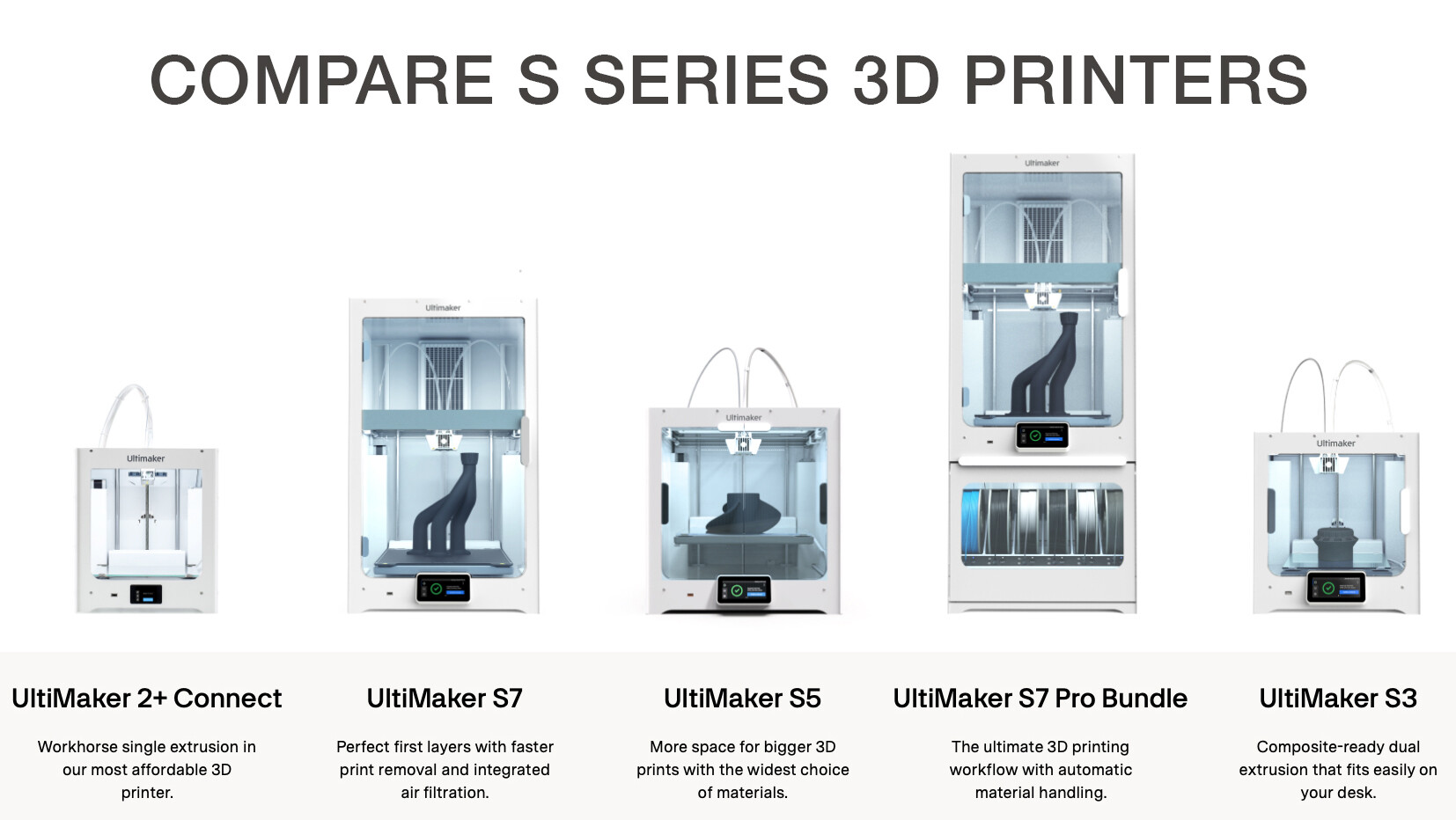

UltiMaker S5 Pro Bundle (918273)

Click the yellow arrows to view multiple buying options...

- Description

- UltiMaker S5 Air Manager

- UltiMaker S5 Material Station

- Consumables

- Q & A: Benefits & Intended use

- Training

-

Description

UltiMaker S5 Pro Bundle (918273): Rely on the seamless performance of the Ultimaker S5 with its cutting-edge active bed leveling ensuring an impeccable initial layer, setting the foundation for precision in your 3D prints. The inclusion of glass doors not only enhances the aesthetics but also regulates airflow within the chamber, ensuring stable and consistent printing conditions. The dual filament flow sensors will pause your print and notify you if you run out of material.

Complete your 3D printing operation workflow with the S5 PRO BUNDLE with the included:

Complete your 3D printing operation workflow with the S5 PRO BUNDLE with the included: - ULTIMAKER S5 AIR MANAGER

- ULTIMAKER S5 MATERIAL STATION

** PLEASE REFER TO THE RELEVANT TAB FOR MORE INFO ON THESE ACCESSORIES** With the Ultimaker S5, you are not only getting a market-leading 3D printer you gain access to the Ultimaker platfom. Access all the tools you need to start 3D printing increased security, workflow management, and knowledge. Ultimaker brings it to your door, with features including a limited Digital Library for easy part storage and sharing, an IT knowledge base, and e-learning courses.

MAIN FEATURES:

- HASSLE-FREE EXPERIENCE: Seamless integration with the Ultimaker platform of software, materials, and printers

- HIGH BUILD VOLUME TO SIZE RATIO: Scale up with bigger parts or batch production

- TOUCHSCREEN CONTROL: Effortless operation via an award- winning user interface

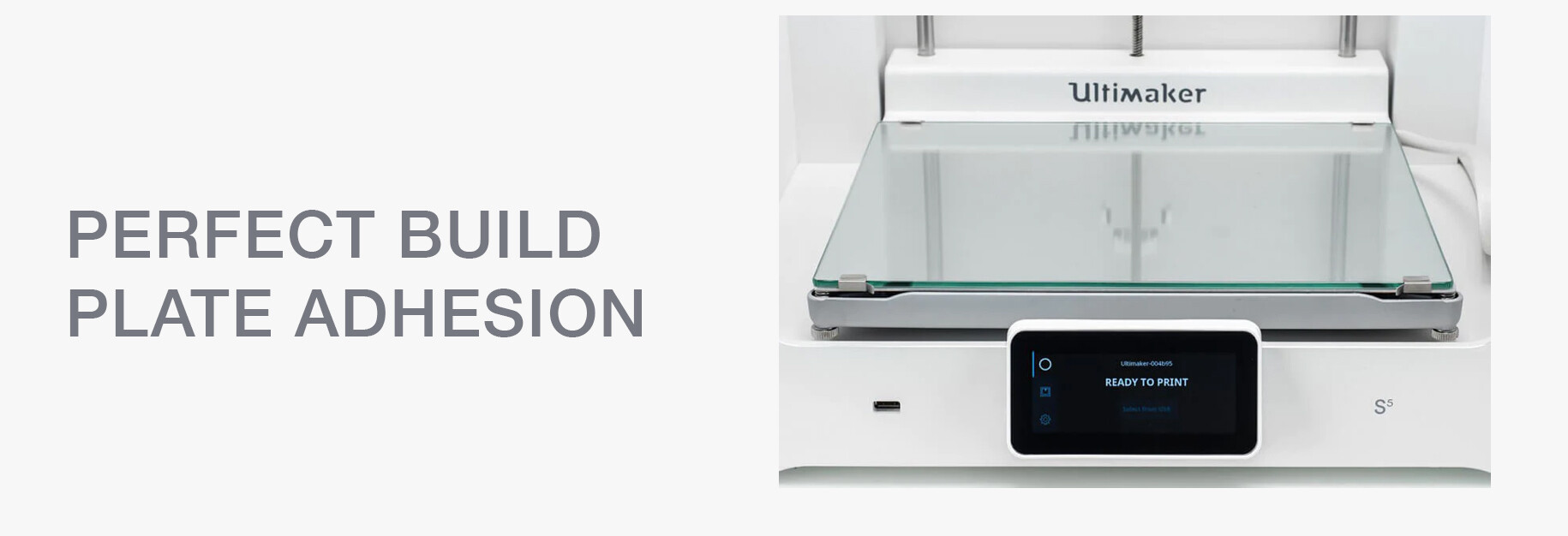

- ADVANCED ACTIVE LEVELLING: Reliable first-layer adhesion, enables unattended use without manual levelling

- WIDE MATERIAL CHOICE: Use almost any material with our open filament system, including composites (requires print core CC)

- EASY SETUP & MONITORING: With NFC material recognition and internal camera

- NETWORK CONNECTIVITY: Print via Wi-Fi, LAN, cloud, or USB

- MINIMAL TRAINING REQUIRED: Anyone can print after a 30-minute introduction

- ULTIMAKER ESSENTIALS: Unending access to security-assessed software – with remote printing, user management, and e-learning

Winner of the 2019 iF Design Award, the Ultimaker S5 boasts an intelligently designed touchscreen interface that streamlines every interaction. From a user-friendly step-by-step setup to seamless navigation and maintenance processes, this award-winning interface eliminates the necessity for extensive training, providing a hassle-free and intuitive 3D printing experience. The carefully crafted design not only ensures efficiency but also enhances the overall accessibility of the printing system, making it a standout choice for both novices and experienced users alike.

The Ultimaker S5 is built to run continuously and maximise uptime. Its best-in-class technical specifications deliver performance you can rely on. Designed for your success, the Ultimaker S5 is part of the complete Ultimaker 3D printing solution – one trusted by hundreds of thousands of professionals worldwide.

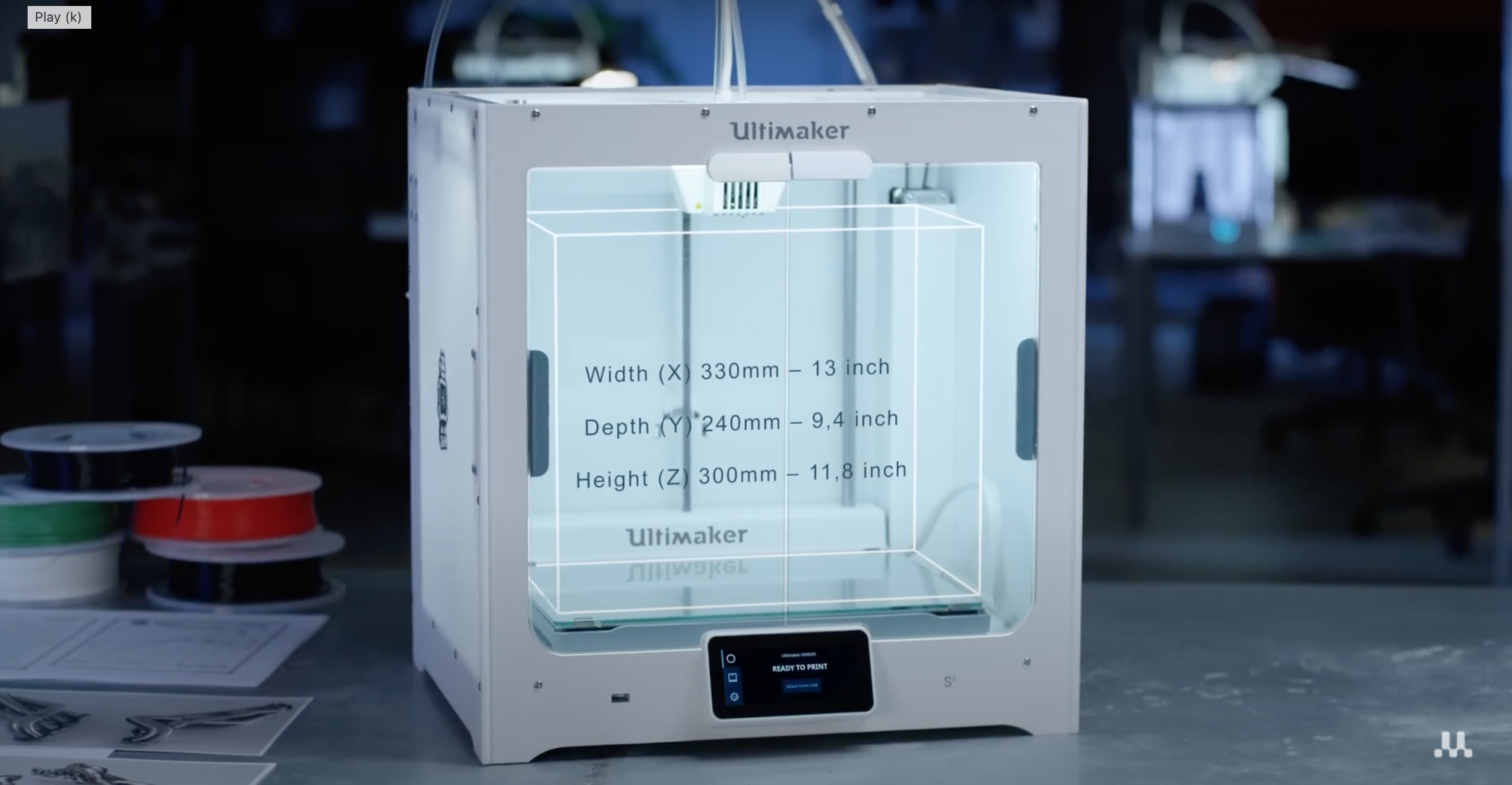

- Large build volume: 330 x 240 x 300 mm (13 x 9.4 x 11.8 inches)

- Compatible with high-strength glass and carbon fiber filament

- Down to 20 micron (0.001 inch) layer resolution

- Open filament system – print with any 2.85 mm material

- 4.7-inch touchscreen interface – Winner of iF Design Award 2019

With a generous build volume of 330 x 240 x 300mm (13 x 9.4 x 11.8 inches), the possibilities expand as you gain the freedom to create larger designs or simultaneously print multiple parts on a single build plate. This versatility allows you to meet production demands with maximum efficiency, all while enjoying the convenience of a 3D printer that comfortably resides on your desk. Whether you're crafting sizable prototypes or efficiently producing batches of intricate components, the ample build space ensures that your creative vision is not limited by size constraints.

Multi-point probing with the print head's capacitive sensor compensates for tiny variations in build plate topography, resulting in an always-perfect first layer.

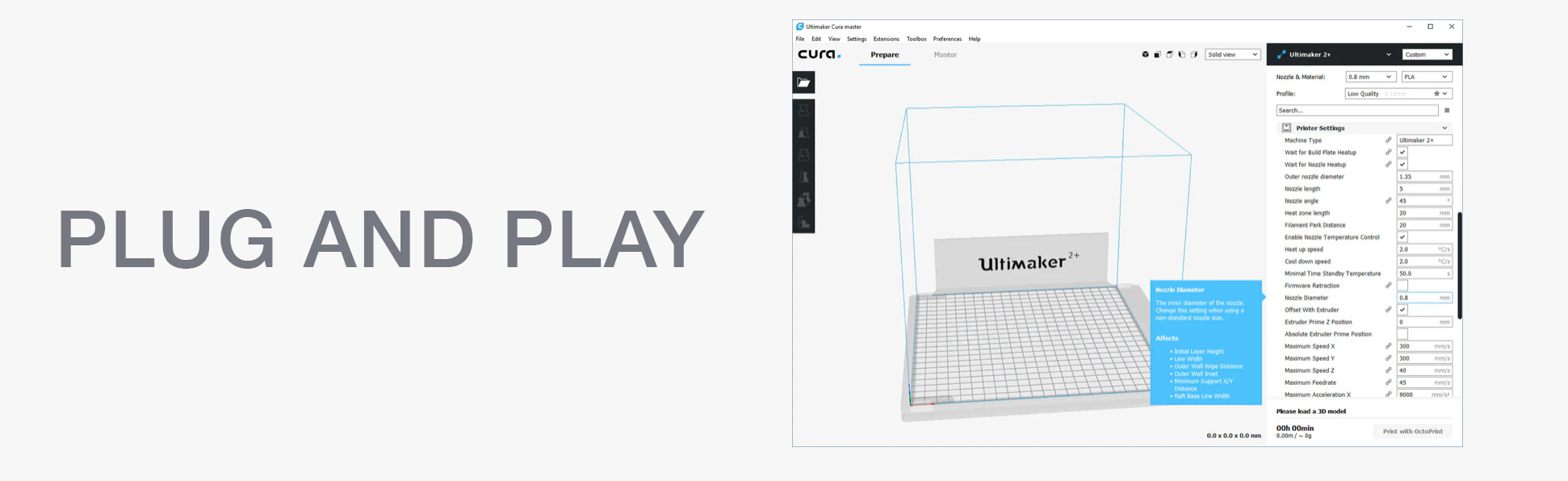

Maximise your 3D printing efficiency by leveraging the proven and predefined print settings offered by Ultimaker Cura. These settings go beyond just Ultimaker's proprietary materials; they encompass a continually expanding library of print profiles sourced from top materials brands, conveniently accessible through the Ultimaker Marketplace. This collaborative platform ensures that you have access to a diverse range of print configurations, tailored to various materials, guaranteeing optimal results for your specific project needs.

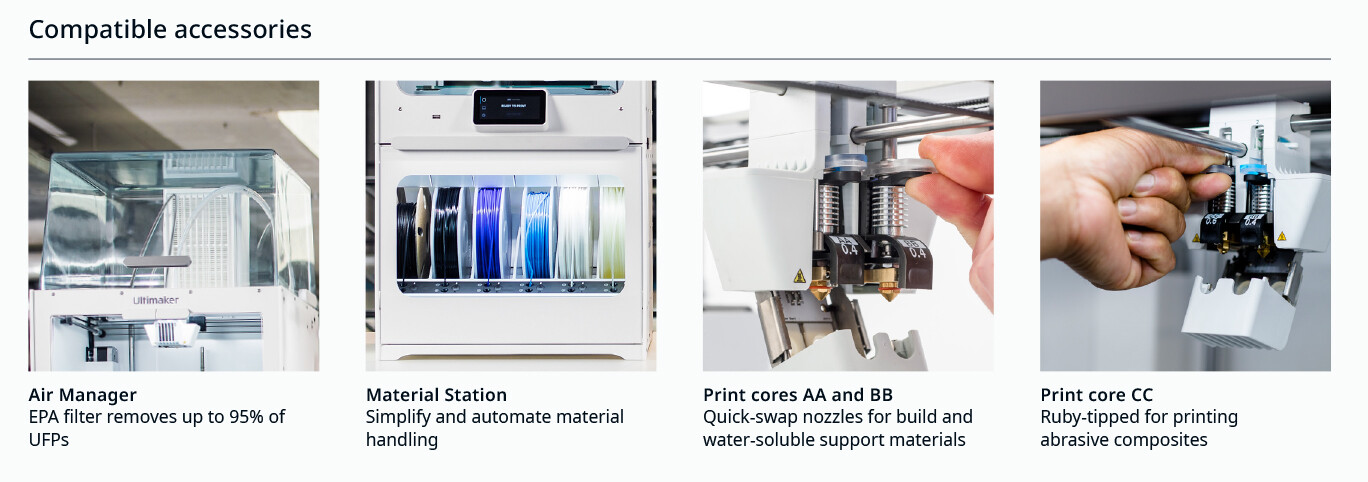

The Ultimaker S5 provides a seamless workflow with the world's most advanced filaments, including cutting-edge glass and carbon fibre composites. When working with non-abrasive filaments, the printer offers quick and effortless transitions between build and support materials. Users can choose from 0.8, 0.4, or 0.25 mm print cores, catering to the demands of fast or intricately detailed prints. For those seeking to unlock the potential of high-end applications using abrasive materials integrate the separately sold print core CC Red 0.6 to ensure versatility and precision in a variety of 3D printing applications.

Award-winning line of 3D printers stands as a testament to Ultimaker's robust, reliable, and user-friendly nature. These printers consistently deliver high-quality parts with unwavering precision. Meticulously designed and rigorously tested for continuous operation 24/7, they provide a seamless and efficient workflow, allowing you to achieve your desired results with speed and ease.

Featuring an open filament system, Ultimaker allows users to explore and select materials tailored precisely to their application needs. Whether seeking heat resistance, chemical resilience, wear resistance, or flexibility, Ultimaker's extensive material options empower users to fine-tune and optimize the properties of their prints.

Ultimaker Cura seamlessly integrates into any workflow, providing unparalleled flexibility through the utilization of Ultimaker Marketplace plugins. These plugins serve as dynamic extensions, allowing users to tailor their 3D printing processes to specific needs and preferences.

Ultimaker's extensive global network of service partners is dedicated to providing professional assistance, offering services such as installation, training, and maintenance in your preferred language and time zone. This ensures Ultimaker users around the world have access to localised support, making the experience of setting up, learning, and maintaining your 3D printer both convenient and tailored to your specific needs.

-

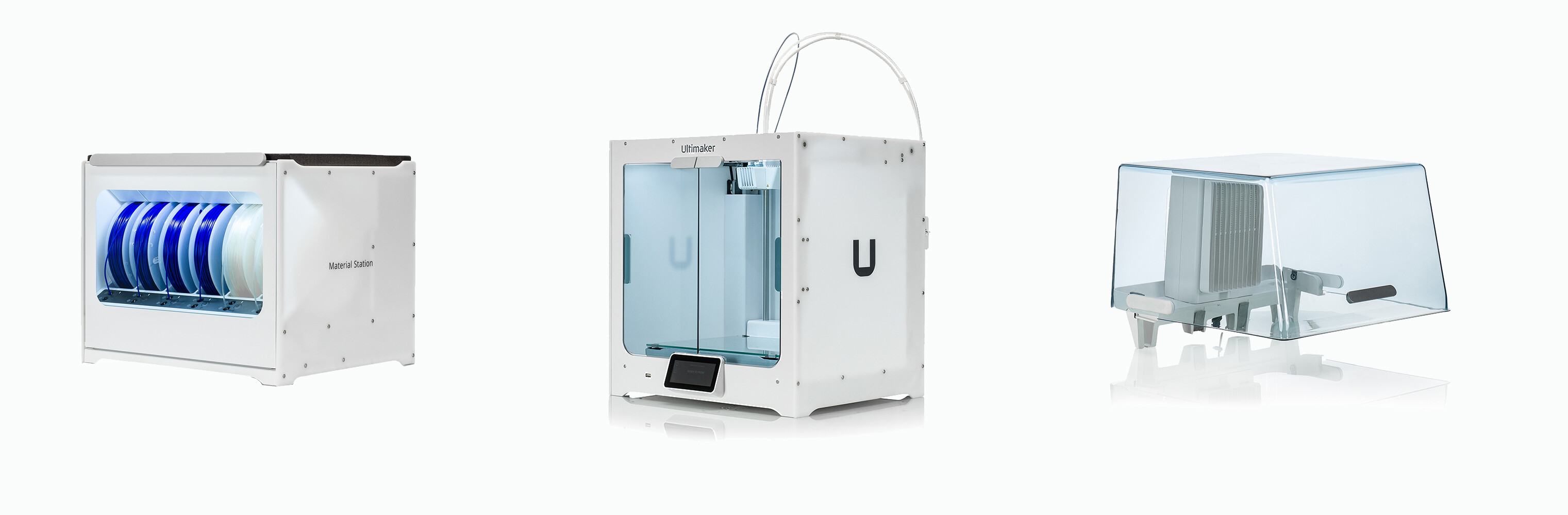

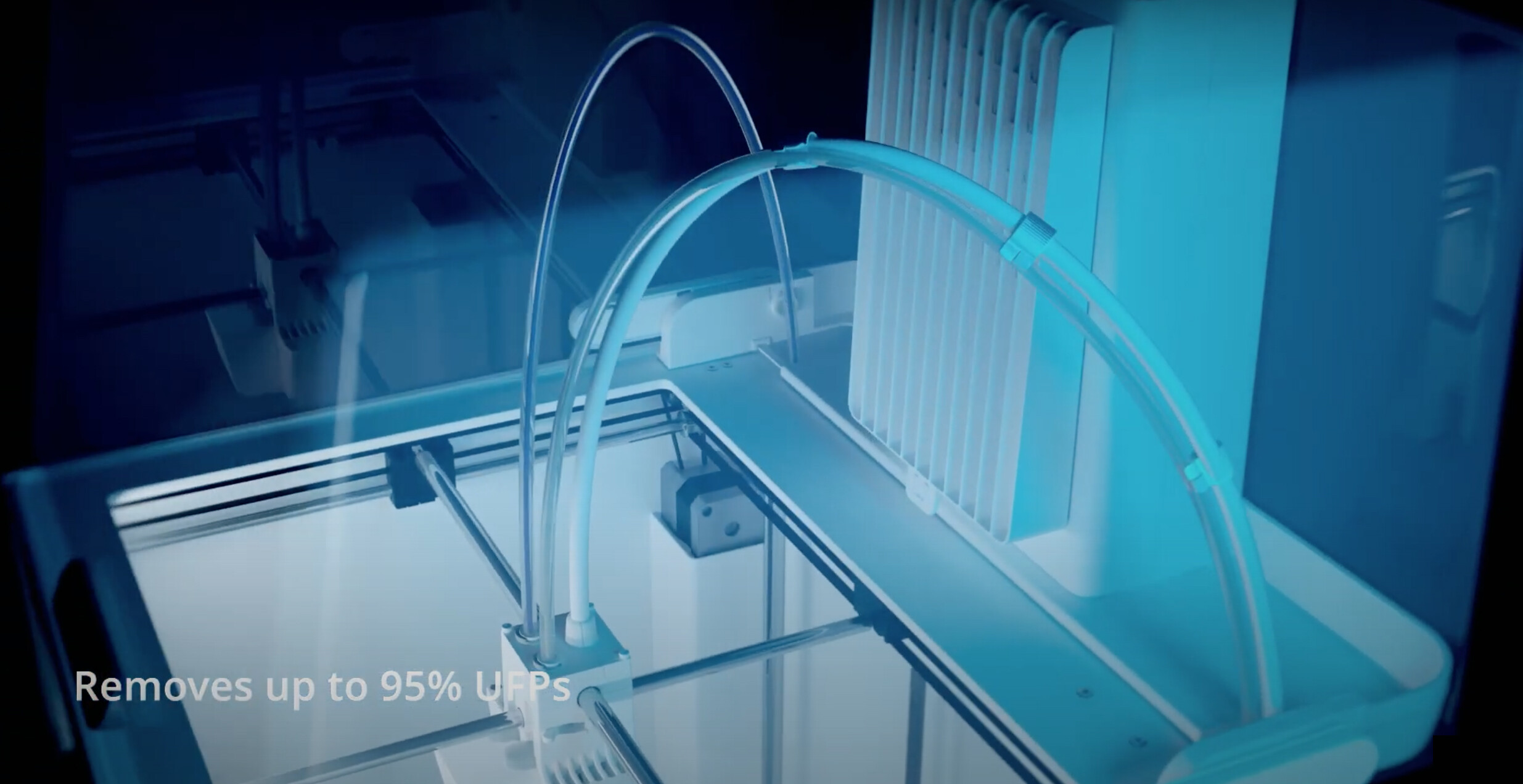

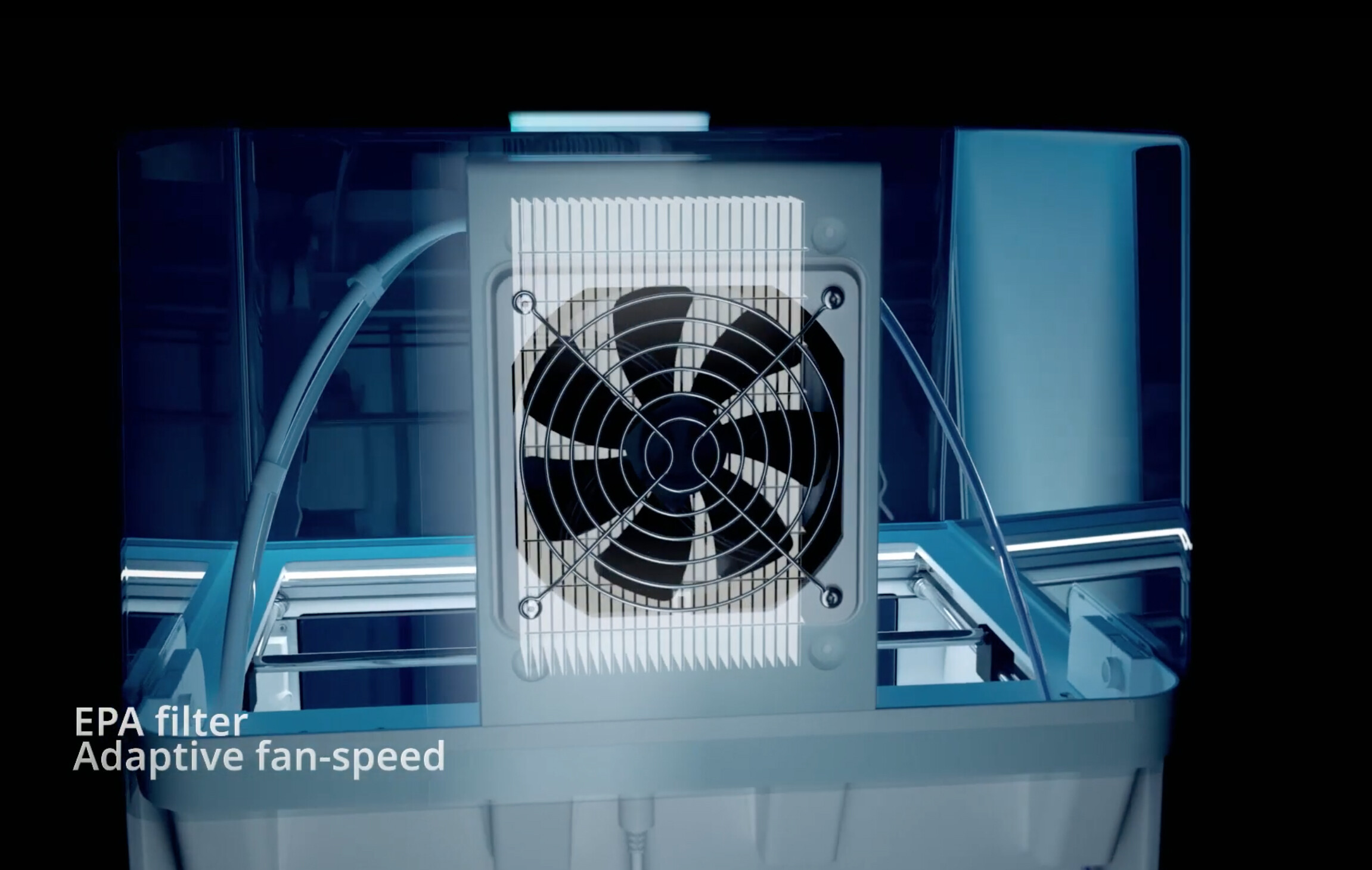

UltiMaker S5 Air Manager

With the Ultimaker S5 Air Manager, experience an enhanced 3D printing environment featuring a closed, inside-out airflow system throughout the entire printing process. This innovative design ensures superior control within the build chamber and effectively filters up to 95% of ultrafine particles generated during printing.

IMPROVED QUALITY, SAFER WORKPLACE:

The Ultimaker S5 Air Manager ensures a safer working environment, providing a closed, inside-out airflow for the Ultimaker S5 3D printer. It filters up to 95% of all ultrafine particles (UFPs) emitted during 3D printing and forms a safe, physical barrier to the print area.

MORE MATERIALS, LESS HASSLE:

Optimised software profiles precisely control filtering for every Ultimaker material and over 40 third-party filaments. So you can focus on creating the perfect 3D printed part with any material you choose. No worries about UFPs, and no extra time configuring your printer.

KEY FEATURES:

- EPA FILTER: Removes up to 95% of UFPs

- CONTROLLED EXTRACTION: Inside-out airflow optimised for filtering and print quality

- ENHANCED SAFETY: Physical barrier prevents reaching inside the printer

- OPTIMISED FOR YOUR APPLICATIONS: Detects material being used and adjusts airflow

- EASY SETUP: Printer detects when the Air Manager is connected

- SMART MONITORING: Printer tracks filter usage and prompts replacement

WHAT'S IN THE BOX:

- Mounting bracket

- Filter housing

- Filter

- Cover

- Air Manager cable

- Cable clips (3x)

- Hex key 2.5 mm*

- Hex bolts M4 x 16 mm (4x)*

- Removal tools*

*Not required for installation

-

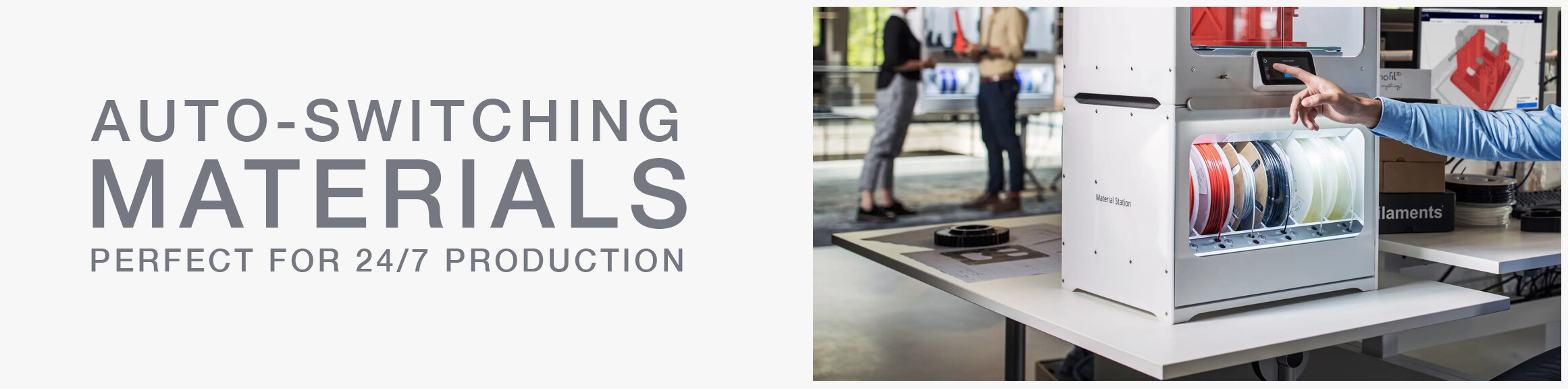

UltiMaker S5 Material Station

The Ultimaker S5/S7 Material Station marks an important contribution to a ‘no-hassle’ office solution. As part of the Ultimaker S5 Pro Bundle, it features easy front loading for up to six spools of filament, end-of-filament detection, NFC recognition with compatible materials, and automatic material switching.

The Ultimaker S5 Material Station stands as an advanced humidity-controlled chamber designed to accommodate six material spools, allowing flexible loading of up to 4.5kg of material in any order. Boasting cutting-edge features, each bay within the station incorporates automatic material switching, composite-ready feeder wheels, and filament flow sensors.

KEY FEATURES:

- FAST & EASY LOADING: Front-facing bay for up to six materials reduces loading time to a few seconds

- UNINTERRUPTED PRINTING: Sensors detect when one material spool ends and automatically loads the next

- HUMIDITY CONTROL: Intelligent atmospheric management keeps relative humidity below 40%

- EASY SET-UP & MONITORING: NFC material auto- recognition and seamless integration with Ultimaker software

- COMPOSITE MATERIALS COMPATIBLE: Print parts with high strength and unique properties

- LIMITLESS CONFIGURATIONS: Keep your most-used materials ready to print when you need – Ultimaker and third-party filaments

-

Consumables

Unlock a wide range of applications with Ultimaker materials or use almost any 2.85mm filament available on the market.

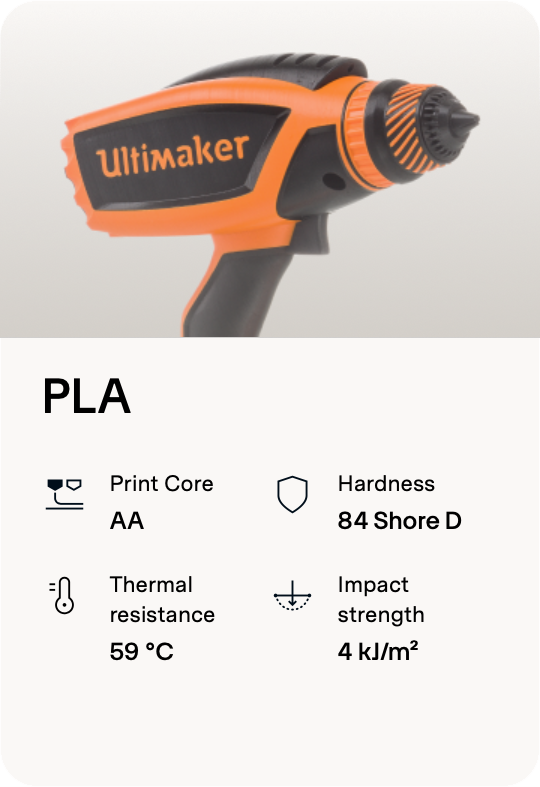

EASY TO PRINT:

Ultimaker PLA (750g)

- PLA - Green - 750g (1608)

- PLA - Black -750g (1609)

- PLA - Silver Metallic - 750g (1612)

- PLA - White - 750g (1613)

- PLA - Transparent - 750g (1614)

- PLA - Orange - 750g (1615)

- PLA - Blue - 750g (1616)

- PLA - Magenta - 750g (1617)

- PLA - Red - 750g (1618)

- PLA - Yellow - 750g (1619)

- PLA - Pearl White - 750g (1620)

Ultimaker Tough PLA (750g)

- Tough PLA - Black - 750g (202300)

- Tough PLA - White - 750g (202301)

- Tough PLA - Red - 750g (202302)

- Tough PLA - Green - 750g (202303)

- Tough PLA - Grey - 750g (202304)

- Tough PLA - Yellow - 750g (202305)

- Tough PLA - Blue - 750g (202306)

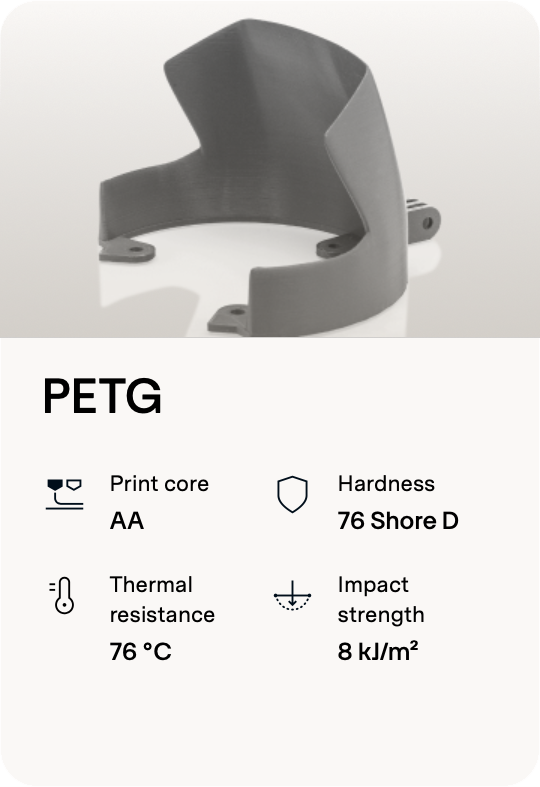

Ultimaker PETG (750g)

- PETG - Black - 750g (227282)

- PETG - White - 750g (227293)

- PETG - Silver - 750g (227326)

- PETG - Grey - 750g (227329)

- PETG - Green - 750g (227330)

- PETG - Transparent - 750g (227332)

- PETG - Blue - 750g (227333)

- PETG - Blue Translucent - 750g (227335)

- PETG - Red - 750g (227336)

- PETG - Red Translucent - 750g (227337)

- PETG - Green Translucent - 750g (227338)

- PETG - Yellow - 750g (227340)

- PETG - Yellow Fluorescent - 750g (227342)

- PETG - Orange - 750g (227343)

MECHANICAL STRENGTH:

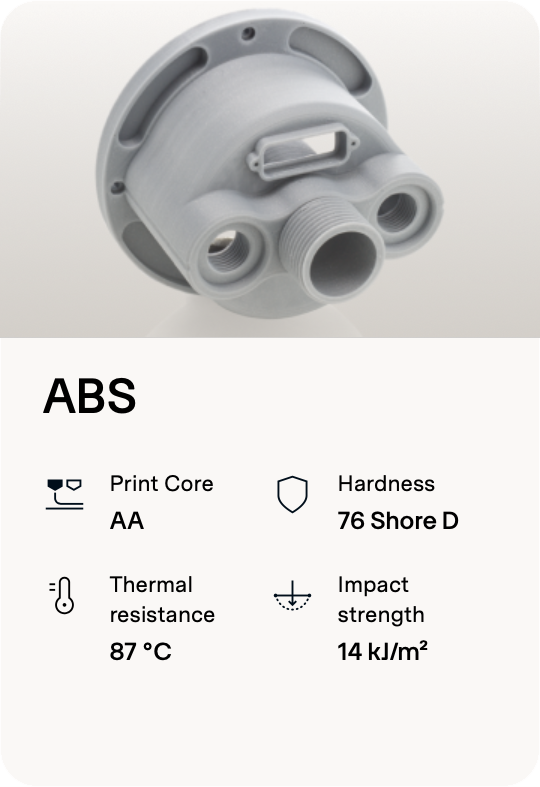

Ultimaker ABS (750g)

- ABS -Black - 750g (1621)

- ABS -White - 750g (1622)

- ABS -Red- 750g (1623)

- ABS -Blue- 750g (1624)

- ABS -Silver- 750g (1625)

- ABS -Pearl Gold - 750g (1626)

- ABS -Green - 750g (1627)

- ABS -Orange - 750g (1628)

- ABS -Yellow - 750g (1629)

- ABS -Grey - 750g (1630)

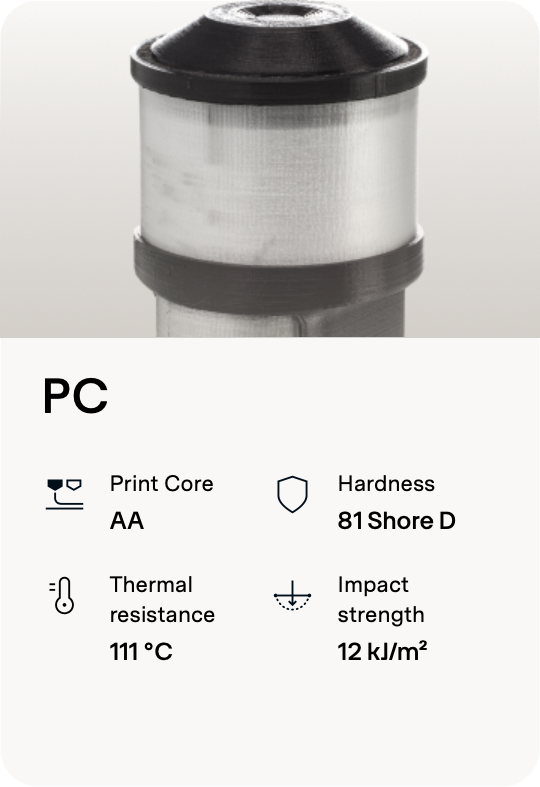

Ultimaker PC (Polycarbonate) (750g)

- Polycarbonate - Transparent - 750g (1640)

- Polycarbonate - Black - 750g (1641)

- Polycarbonate - White - 750g (1642)

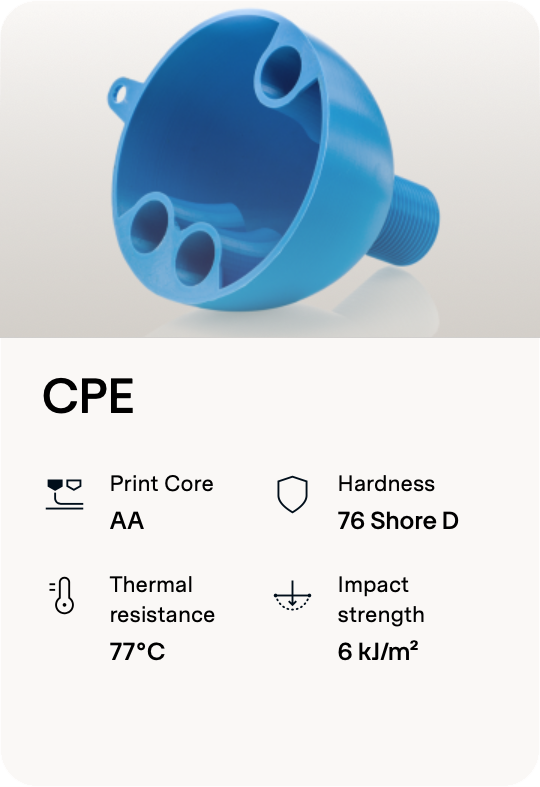

Ultimaker CPE (750g)

- CPE - Black - 750g (1631)

- CPE - White - 750g (1632)

- CPE - Light Grey - 750g (1633)

- CPE - Dark Grey - 750g (1634)

- CPE - Red - 750g (1635)

- CPE - Blue - 750g (1636)

- CPE - Yellow - 750g (1637)

- CPE - Green - 750g (1638)

- CPE - Transparent - 750g (1639)

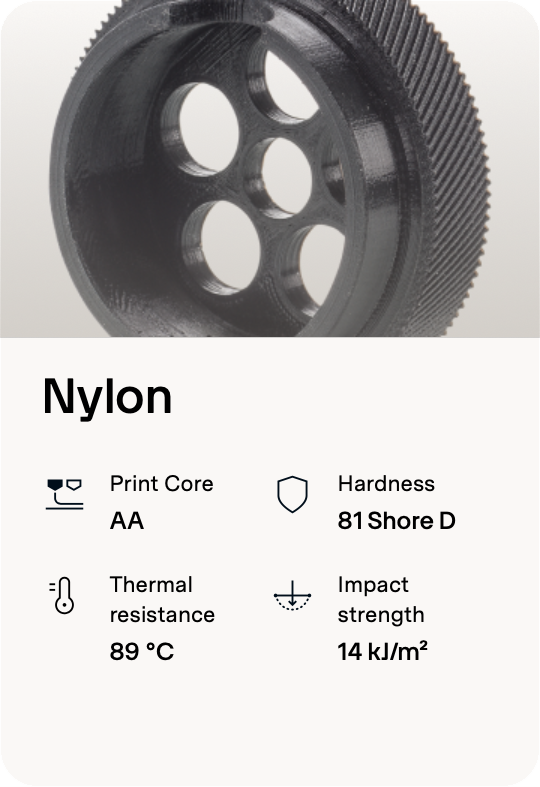

WEAR RESISTANCE:

Ultimaker Nylon (750g)

- Nylon - Black - 750g (1646)

- Nylon -Transparent - 750g (1647)

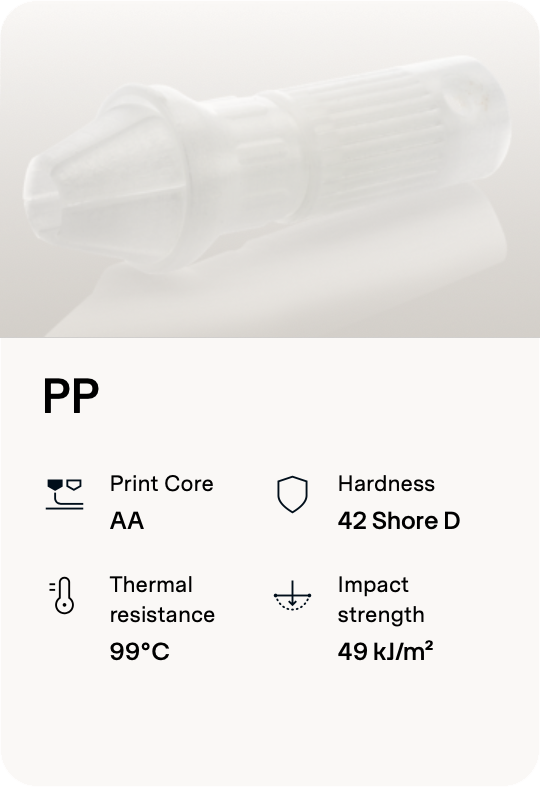

Ultimaker PP (500g)

- Polypropylene – Natural - 500g (1785)

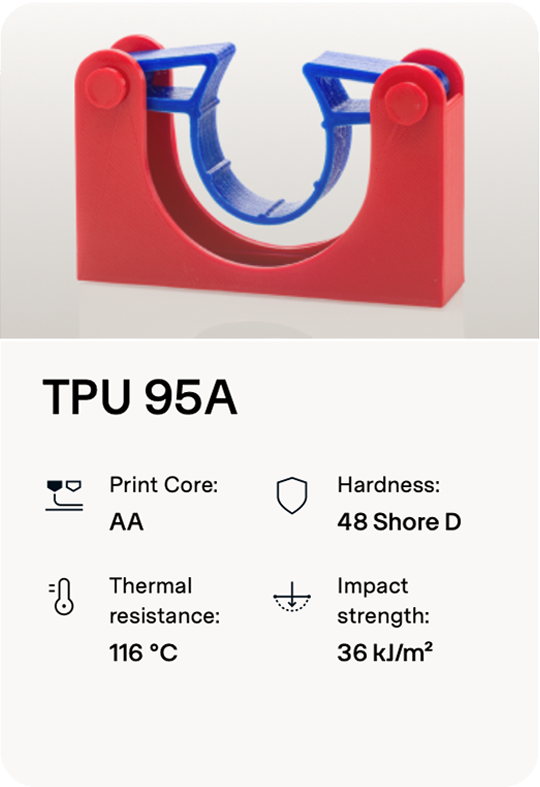

Ultimaker TPU 96A

- Ultimaker TPU 95A Blue Filament 750g (1334)

- Ultimaker TPU 95A Red Filament 750g (1731)

- Ultimaker TPU 95A White Filament 750g (1755)

- Ultimaker TPU 95A Black Filament 750g (1756)

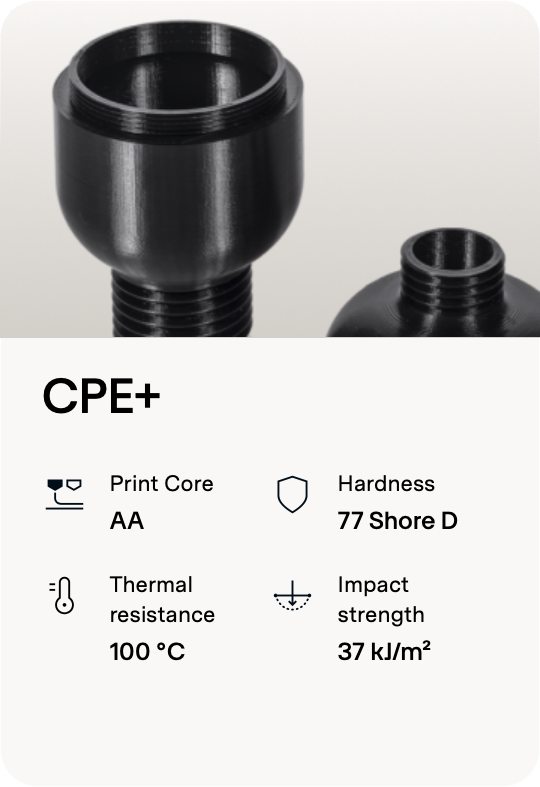

HEAT RESISTANCE:

CPE (co-polyester) materials stand out for their exceptional qualities, showcasing chemical resistance, toughness, and impressive dimensional stability. This makes CPE a preferred material for a wide range of applications, including both functional prototypes and mechanical parts. While both CPE and CPE+ share similar performance characteristics, CPE+ offers additional advantages. Notably, it boasts higher temperature resistance and increased impact strength, making it an excellent choice for applications where these specific attributes are crucial. Whether opting for CPE or CPE+, users can rely on these co-polyester materials to deliver durability and reliability in the creation of functional and robust 3D-printed components.

CPE VS CPE+

- CPE offers a diverse selection of colors, providing users with a broad palette to choose from. This includes the sophisticated greyscale option, which adds a professional touch to 3D-printed models.

- CPE exhibits notable strength with higher tensile and flexural strength. On the other hand, CPE+ takes toughness to the next level. Formulated to be up to 10 times tougher than standard CPE, CPE+ is engineered to provide enhanced durability and resilience.

- CPE+ features a temperature resistance of up to 100ºC when compared to CPE, which is only resistant up to 70ºC

Ultimaker CPE+

- Ultimaker CPE+ Transparent Filament 700g (1643)

- Ultimaker CPE+ Black Filament 700g (1644)

- Ultimaker CPE+ White Filament 700g (1645)

-

Q & A: Benefits & Intended use

BENEFITS:

What is the added value of the Air Manager and Material Station to the Ultimaker S5?

By boosting the award-winning Ultimaker S5 with the custom-engineered Material Station and Air Manager, you can now transform your office 3D printing workflow with automated material handling, optimised air filtration, and filament humidity control. Together, the Ultimaker S5 Pro Bundle boosts productivity, flexibility, and confidence to unlock demanding applications with an extended range of materials.

How does the Ultimaker S5 Pro Bundle enable more applications?

The Ultimaker S5 Pro Bundle’s Air Manager and Material Station enable more applications in two ways. Because of its ultrafine particle filtering of up to 95%, the Air Manager allows safe use of more materials. Extending the range of materials automatically leads to a wider application range that the product can be used for. The Material Station brings flexibility to applications because of its optimised material handling benefits. This allows for optimised and more efficient creation of parts for more applications.

For what applications is the Ultimaker S5 Pro Bundle suitable?

The Ultimaker S5 Pro Bundle can be used for a wide range of applications. Although the individual products were initially designed for desktop applications (visual models, prototypes, and concept models), the Ultimaker S5 Pro Bundle stretches the application range also towards industrial applications, such as manufacturing aids, functional prototypes and even end-use parts. These are applications that some customers have already printed on the Ultimaker S5 and Ultimaker 3, but the Ultimaker S5 Pro Bundle will enhance and optimise the creation of these applications even more.

For what markets is the Ultimaker S5 Pro Bundle most suitable?

The full S-line is designed to meet the needs of a wide range of professionals, industries and markets. The Ultimaker S5 has already been proven to be successfully used in segments such as automotive, architecture, product design, manufacturing, and education. The Ultimaker S5 Pro Bundle expands the possibilities even more so, by allowing use in more industrial markets as well.

How does the Ultimaker S5 Pro Bundle contribute to higher productivity?

The Material Station and Air Manager empower the Ultimaker S5 to deliver high-quality 3D printed parts and models at maximum output. Together, the Ultimaker S5 Pro Bundle’s material capacity and end-to-end material handling, including automatic switching to a new spool when one runs out, increases print success rate, print quality, and uptime to 24/7 reliable production – while minimizing human error, print job time, and operator time.

Who are the primary target users for the Ultimaker S5 Pro Bundle?

The Ultimaker S5 Pro Bundle enables designers, engineers, manufacturers, architects, and innovators getting the most out of their business by boosting productivity, flexibility, and confidence to unlock demanding applications with an extended range of materials.

Why did Ultimaker develop the Material Station?

The development of the Material Station is based on customer research performed by Ultimaker’s Product Management department. Ultimaker discovered that material handling was not fit for actual use (e.g. users experienced humidity problems and the filament loading process was experienced as not convenient). With the Material Station, Ultimaker wants to take the usability and material handling of the Ultimaker S5 to the next level.

What are the main features of the Material Station?

The Ultimaker S5 Material Station boosts and simplifies the 3D printing workflow, while delivering a more efficient, utterly reliable solution for material handling and storage. The main features are listed here:

- Fast and easy loading: Front-facing bay for up to six materials reduces loading time to a few seconds

- Uninterrupted printing: Sensors detect when one material spool ends and automatically loads the next

- Humidity control: Intelligent atmospheric management keeps relative humidity below 40%

- Easy setup and monitoring: NFC material auto-recognition and seamless integration with Ultimaker software

- Composite materials compatible: Print parts with high strength and unique properties

- Limitless configurations: Keep your most-used materials ready to print when you need – Ultimaker and third-party filaments

Why did Ultimaker develop an Air Manager?

Ultimaker identified an increasing concern about the emission of ultrafine particles in the 3D printing market and saw that this is perceived as a serious health risk. The Air Manager was developed to take away these concerns and to facilitate 3D printing with greater peace of mind.

What are the main features of the Air Manager?

The Ultimaker S5 Air Manager is designed to ensure a safer working environment by filtering up to 95% of all ultrafine particles (UFPs) emitted during 3D printing and creating a safe barrier around the build chamber. In short, these are the main features:

- EPA filter: Removes up to 95% of UFPs

- Controlled extraction: Inside-out airflow optimised for filtering and print quality

- Enhanced safety: Physical barrier prevents reaching inside the printer

- Optimized for your application: Detects material being used and adjusts airflow

- Easy setup: Printer detects when Air Manager is connected

- Smart monitoring: Printer tracks filter usage and prompts replacement

Is printing with the Air Manager automatically safe? And if so, does that mean it’s not safe to print without the Air Manager?

Exactly how safe printing is depends on various factors, such as the material being used, room size, ventilation rate, amount of printers, or other sources of emissions in the room. Nonetheless, we can say that for Ultimaker materials the ultrafine particle emissions stay below an acceptable limit based on one printer in a room of 30 m³ with an air exchange rate of 1.8, even without an Air Manager. When an Air Manager is installed ultrafine particles will be eliminated to a large extent, which would enable more printers in one room. How many exactly depends on the customer’s specific situation. For more information on this topic we would like to refer (users) to a white paper that will be released alongside the new products.

-

Training

Ultimaker 3D Printer training is available to cover all aspects of your new 3D printer including advanced level with the “Design for Additive” half day extension course, training is for up to 3 people on site with delivery of your new Ultimaker & we also run regular training courses at our Stoke Offices and for larger groups at our Worcester HQ , Bristol or Derby facilities.

INST002 INSTALLATION & TRAINING PACKAGES *

* INSTALLATION (IN CONJUNCTION WITH CUSTOMER):

Unboxing of printer and material station – connect units together Setup of Printer onto the network Setup of the printer into Cura and the Digital factory

* TRAINING (SOFTWARE & HARDWARE):

- Using Cura Slicing software to prepare parts for printing

- Cura setting

- Preview of time to print and cost to print

- Submitting prints

- Monitoring prints

- Loading and unloading of material on the printer

- Changing Cores

- Maintenance of the printer

- Tips and tricks

DfAM002 DESIGN FOR ADDITIVE (½ DAY) * & **

** DESIGN FOR ADDITIVE MANUFACTURING COURSE:

- Design rules for manufacturing

- Designing for FDM

- Exporting from CAD

- Orientation considerations

- Walls and Ribs

- Slice height and toolpaths

- Self-supporting designs

- Sectioning parts

- Assemblies / Moving parts

- Threads / Inserts

- Infills Tolerances

- Design samples discussed

- Various exercises to be completed though out the session