- CAD Plotters

- Wide-Format Photo, Fine Art & Graphic Printers

- HP Latex, Outdoor, Signage, Wall Paper Printers & Cutters

- Wide Format Ink & Media Supplies

- Multi Functional Printers & Plan Copiers

- Large Format Scanners

- Finishing - Large Format Paper Folders, Trimmers, XY Cutters & Laminating

- Canon A4 and A3 Copier Paper

- Canvas, Stretcher Bars & Laminate

- Fabric Printers

- 3D Printers

- Bricsys BricsCAD® Software

- Colour Management & RIP Software

- Plotter Warranties

- Storage & Filing Systems

- OFFERS

Why use plot-IT?

- Est since 1965

- Group turnover - £15 million

- 5 UK offices with over 100 staff

- HP Designjet Warranty Provider

- Autodesk Gold reseller

- Canon Elite Partner

- Stratasys - Gold Partner

Ultimaker Print Core BB 0.8mm (9532)

-

Description

Ultimaker Print Core BB 0.8mm (9532): Tailored to match specific materials, these Print Cores redefine efficiency, ensuring optimal print performance and uninterrupted machine operation.

**NOTE: The BB 0.8mm Print Core is ONLY intended for use with PVA water soluble support material. The internal shape of the nozzle on this print core is different, resulting in improved performance for the PVA material. **

The 0.8mm nozzle allows for faster printing by using thicker layers for printing PVA supports. Since the PVA supports will be removed after the print is completed, this is a good way to increase printing speed without sacrificing print quality for the printed object itself.

Since the PVA supports will be removed after the print is completed, this is a good way to increase printing speed without sacrificing print quality for the printed object itself.

MULTIPLE PRINT CORES, MAXIMUM FLEXIBILITY:

Two nozzle sizes – 0.4mm, enabling you to print detailed parts with higher visual quality, and 0.8mm, for shorter print times and improved efficiency – will result in easier optimisation of composite applications.

The Ultimaker print core BB 0.8 to print with bigger line widths, your composite applications will be ready as quickly as possible – saving you time in a busy, hardworking environment that requires efficiency and speed.

QUICK SWAP - NO TOOLS NECESSARY:

With a quick-swap design, the Ultimaker print core BB – like all Ultimaker print cores – can be quickly and easily changed, tool-free, to meet the requirements of any print job, increasing your efficiency and decreasing downtime.

Plus, the print core's EEPROM chip memorises the size and type of your nozzle, meaning fewer printing errors and an increased chance of success.

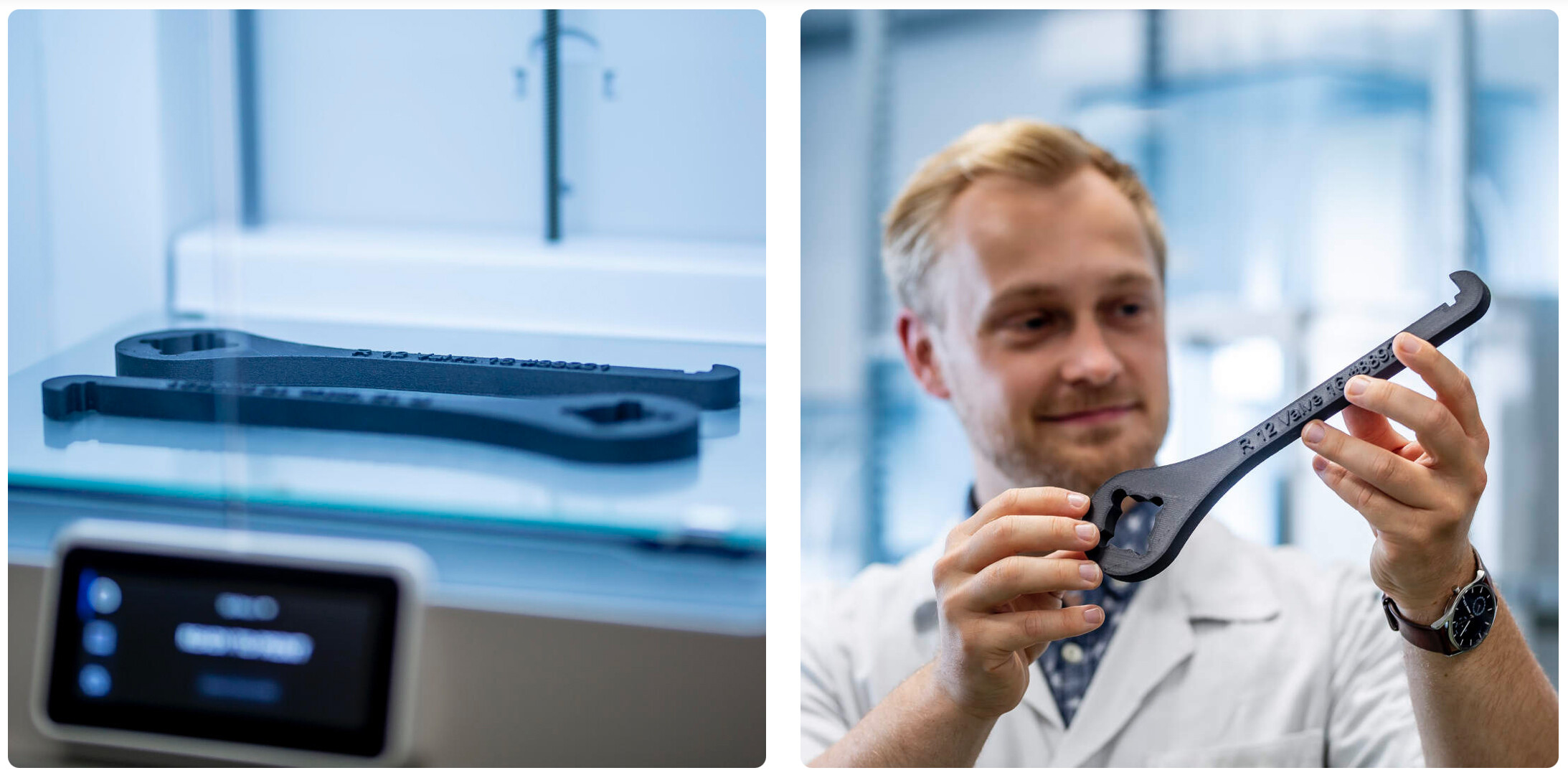

Experience quicker and easier post-processing when using PVA support material for complex parts or stunning visual prototypes, with the Ultimaker PVA Removal Station. Part of UltiMaker's start-to-finish 3D printing platform, it ensures quicker design iterations with minimal operator time and no mess.

A rinsing basket keeps your print in place and completely submerged while dissolving, then lifts up for mess-free draining and print removal.

MAIN FEATURES:

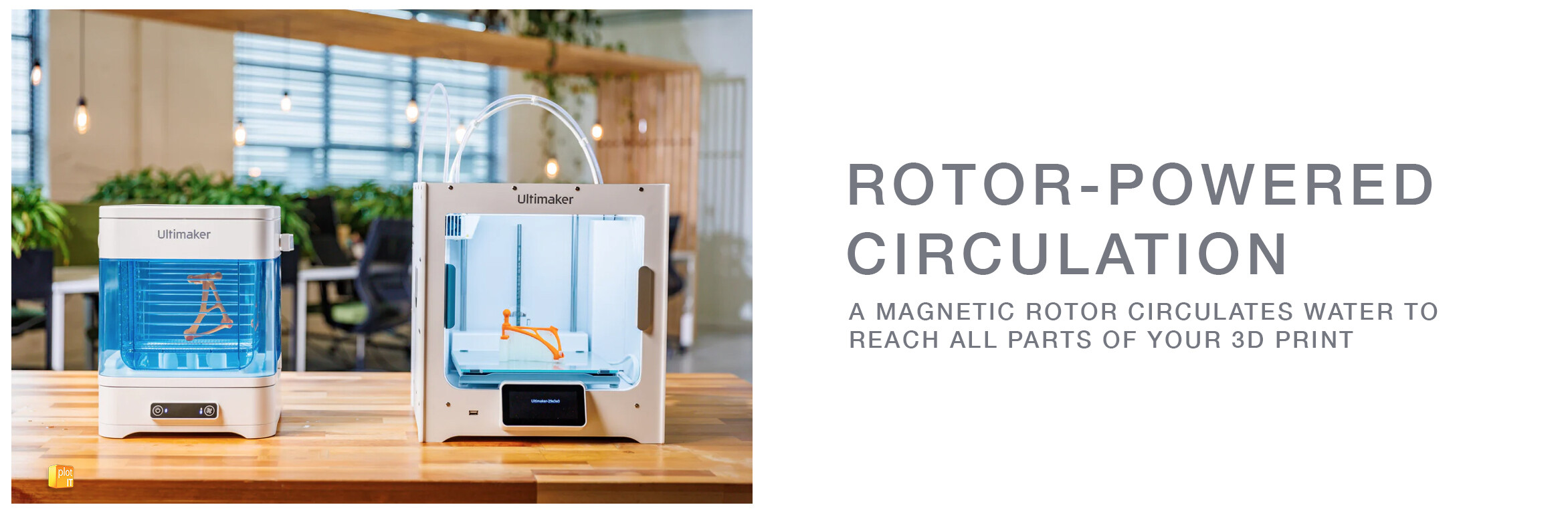

- ROTOR-POWERED CIRCULATION: A magnetic rotor circulates water to reach all parts of your 3D print

- ADJUSTABLE ROTOR SPEED: Adjust for faster dissolving or to protect fragile parts

- KEEPS PRINTS SECURED: A rinsing basket keeps prints in place and submerged

- EASY TO FOLLOW PROGRESS: A transparent, illuminated container makes it easy to know exactly when your part is ready

- LOW MAINTENANCE: Ergonomically designed for easy cleaning

- NO CHEMICALS NEEDED: Just fill with regular tap water, which can be safely disposed of when finished

- CLEAN & NO MESS: Ergonomic design features help keep your workspace clean and tidy

A transparent, illuminated container lets you easily follow the PVA removal process and see when your part is ready. Plus, a saturation indicator shows when to refresh the water.

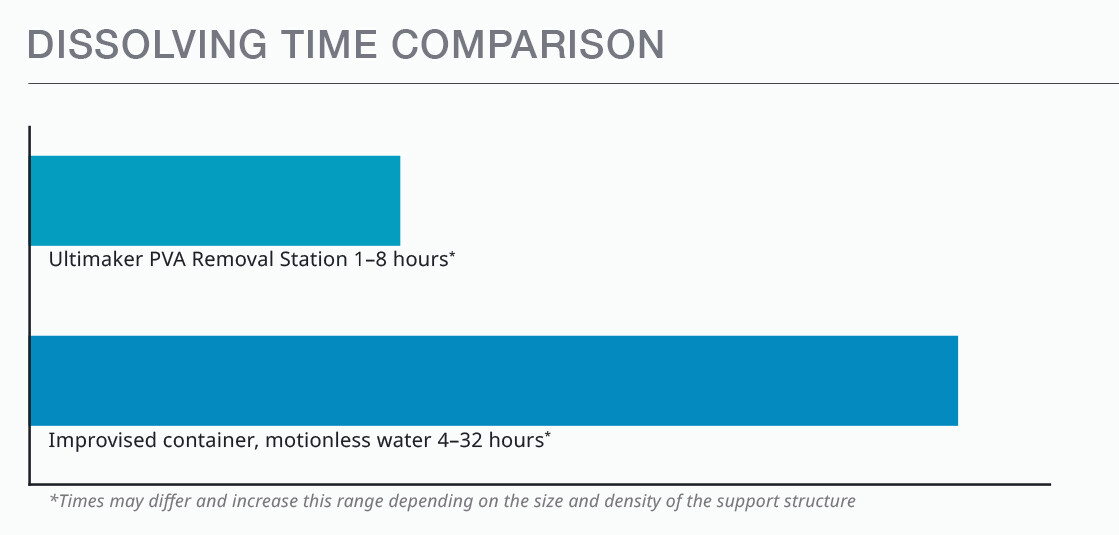

The Ultimaker PVA Removal Station features a high-speed dissolving process driven by a magnetic rotor. Compared with motionless water in an improvised container, it removes PVA up to four times faster – even from hard-to-reach cavities in complex designs. So you have parts ready as soon as possible.

The PVA Removal Station requires only a few minutes of operator time per print, and almost zero maintenance. Just press the start button. Leave it to spin. And collect your print when it’s ready.

Choose 100 or 225 RPM circulation depending on the fragility of your part. Every two minutes, the rotor changes direction to push water evenly against the model. A rinsing basket keeps your print in place and completely submerged while dissolving, then lifts up for mess-free draining and print removal.

-

Print Core Compatibility

PRINT CORE TYPE COMPATIBLE MATERIAL TYPES AVAILABLE SIZES COMPATIBLE PRINTERS AA Build materials and Breakaway support 0.25mm

0.4mm

0.8mmUltimaker 3

Ultimaker S3

Ultimaker S5

Ultimaker S6

Ultimaker S7

Factor 4BB Water-soluble (PVA) support material. On the S8, also used for Breakaway support 0.4mm

0.8mmUltimaker 3

Ultimaker S3

Ultimaker S5

Ultimaker S6

Ultimaker S7

Ultimaker S8

Factor 4CC Composite (glass or carbon-filled) materials 0.4mm

0.6mmUltimaker S3

Ultimaker S5

Ultimaker S6

Ultimaker S7

Factor 4DD* Ultrafuse Support Layer material (Metal Expansion kit) 0.4mm Ultimaker S3

Ultimaker S5

Ultimaker S6

Ultimaker S7

Factor 4HT High-temperature materials such as UltiMaker PPS CF 0.6mm Factor 4 AA+ High-flow, high-speed printing with (non-composite) build materials 0.4mm Ultimaker S5

Ultimaker S6

Ultimaker S7

Ultimaker S8CC+ High-flow, high-speed printing with composite materials 0.4mm Ultimaker S5

Ultimaker S6

Ultimaker S7

Ultimaker S8*The DD print core and Ultrafuse Support Layer material are only available in selected regions.

COMPATIBILITY EXPLANATION:

The AA and BB print cores are compatible with all UltiMaker printers that use print cores (UltiMaker 3, S series, and Factor 4). These print cores are not intended for use with abrasive materials.

The CC print cores are only compatible with UltiMaker printers with abrasion-resistant feeders (S series and Factor 4). These print cores are intended for use with abrasive or composite materials. These print cores cannot be used on the UltiMaker 3, because the UltiMaker 3 feeders are not compatible with composite materials.

See more information about the AA and CC cores on the UltiMaker S8 below.

The CC print cores can also be used in combination with the Material Station. The Material Station has abrasion-resistant prefeeders in all material bays. However, the Material Station is not compatible with all composite materials. Please check the latest profiles in the UltiMaker Marketplace to determine if the material can be used with the Material Station.

The DD cores are not recommended for use with the S series Material Station. The DD print cores currently only support Ultrafuse Support Layer filament, which is used when printing metal. This is not recommended with the S series Material Station due to the curves in the internal filament path. On Factor 4, the filament path is different (smoother) so this does not affect the Ultrafuse material as much.

The HT print cores are only compatible with Factor 4. This print core type is optimized for high-temperature materials, such as UltiMaker PPS CF. This material requires a high printing and build volume temperature to print reliably; only Factor 4 features a heated build chamber.

The AA+ and CC+ print cores feature redesigned nozzles optimised for faster material melting and deposition, ensuring seamless compatibility with UltiMaker Cheetah motion planning. This advanced motion planner is exclusive to the UltiMaker S8.

Regular AA and CC print cores can be used on the S8, but this workflow is not fully supported. These cores are not designed for the high-speed capabilities of the S8. The AA and CC cannot be selected for S8 in Cura; no profiles are developed for this configuration. To use the regular AA and CC cores on the S8, you can slice the print job for UltiMaker S7 instead and print it on S8.

-

Other available sizes