- CAD Plotters

- Wide-Format Photo, Fine Art & Graphic Printers

- HP Latex, Outdoor, Signage, Wall Paper Printers & Cutters

- Wide Format Ink & Media Supplies

- Multi Functional Printers & Plan Copiers

- Large Format Scanners

- Finishing - Large Format Paper Folders, Trimmers, XY Cutters & Laminating

- Canon A4 and A3 Copier Paper

- Canvas, Stretcher Bars & Laminate

- Fabric Printers

- 3D Printers

- Bricsys BricsCAD® Software

- Colour Management & RIP Software

- Plotter Warranties

- Storage & Filing Systems

- OFFERS

Why use plot-IT?

- Est since 1965

- Group turnover - £15 million

- 5 UK offices with over 100 staff

- HP Designjet Warranty Provider

- Autodesk Gold reseller

- Canon Elite Partner

- Stratasys - Gold Partner

UltiMaker S-Series Breakaway Material White 750g Filament (200551)

-

Description

UltiMaker S-Series Breakaway Material White 750g Filament (200551): Ultimaker Breakaway support offers a hassle-free removal process, leaving behind a pristine surface finish unmatched by other support materials. No additional post-processing required for a smooth, high-quality result. This product is approximately 90m long.

Breakaway support enables printing intricate details and overhangs with materials like CPE or ABS, where PVA isn't suitable. It's not just efficient and cost-effective; it's also designed for extended usability and reliable adhesion to your prints, ensuring smooth, precise models with easy removal.

Like build material, Breakaway Material is removed manually. But like PVA, it is a separate material printed with dual extrusion. The result is a balance between the advantages of the other support material options. You can remove Breakaway by hand so there’s no need to wait hours for anything to dissolve, but it also peels away cleanly from the rest of your print so you have an accurate model and don’t need to post-process it.

However, for the smoothest surface finish we still recommend PVA. And the Breakaway material in your print needs to be accessible for you to remove it, so you do not have complete design freedom. Ultimaker Breakaway is optimised for use with ABS, Nylon, PLA, CPE, and CPE+.

KEY FEATURES:

- Good bonding to a variety of build materials

- Robust support while still weak and ductile enough to remove from the model

- Longer shelf life and less moisture sensitivity compared to water-soluble support materials

- High-quality surface finish

- No further post-processing required

APPLICATIONS:

- Breakaway support material for Ultimaker ABS, Nylon, PLA, CPE, and CPE+

-

Quick comparison: When to use...

BUILD MATERIAL SUPPORTS:

When you don’t need a print that is 100% accurate compared to the dimensions of your 3D design. Or if you only have a single extrusion 3D printer.

PVA:

Ideal if you’re printing a complex shape or when you want a really smooth surface finish beneath your supports, but takes several hours to dissolve .

BREAKAWAY:

If you’re short on time, Breakaway is quicker to remove than PVA and keeps the dimensional accuracy of your print, with a quality surface finish.

-

How to remove Breakaway

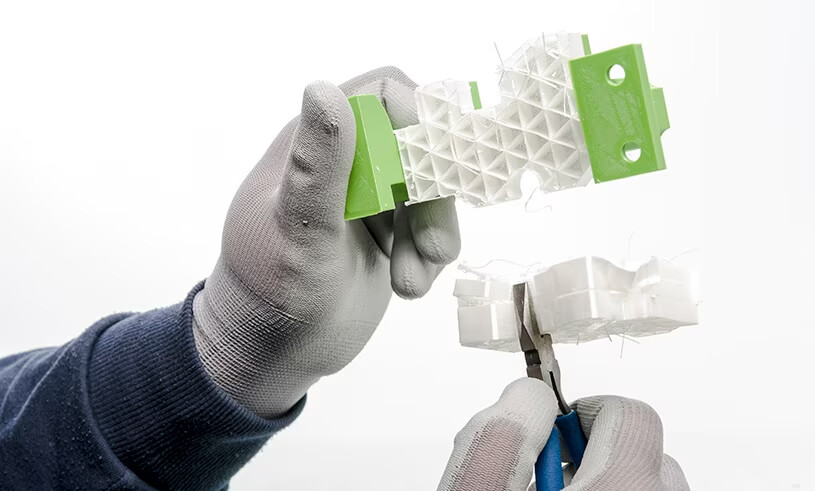

Prints using Ultimaker Breakaway as support material will require post-processing to remove the support structures. This can be achieved by breaking the support structures from the build material as described on this page.

**Note: It is advised to wear protective gloves when the support structure contains sharp corners or when working with bigger models.** TEAR THE INNER SUPPORT STRUCTURE:

Start by removing the walls of the support structure with a gripping plier. This allows you to quickly tear away the majority of the inner support structure.

PULL THE BREAKAWAY SUPPORT FROM THE BUILD MATERIAL:

After removing most of the support structure, the remaining part(s) can be pulled from the build material. Use cutting pliers to grab the Breakaway support in a corner and try to carefully get underneath it, then bend it upwards. Repeat this for several corners, so that you can loosen the support from the model around the corners. After this, pull the Breakaway support from the model.

PEEL THE LAST TRACES FROM THE MODEL:

Sometimes a final layer of the support material remains after pulling the Breakaway support from the build material. If this happens, use cutting pliers to peel it off from a loose edge. Any leftover traces on the model can be removed with a tweezer.