- CAD Plotters

- Wide-Format Photo, Fine Art & Graphic Printers

- HP Latex, Outdoor, Signage, Wall Paper Printers & Cutters

- Wide Format Ink & Media Supplies

- Multi Functional Printers & Plan Copiers

- Large Format Scanners

- Finishing - Large Format Paper Folders, Trimmers, XY Cutters & Laminating

- Canon A4 and A3 Copier Paper

- Canvas, Stretcher Bars & Laminate

- Fabric Printers

- 3D Printers

- Bricsys® CAD Software

- Colour Management & RIP Software

- Plotter Warranties

- Storage & Filing Systems

- OFFERS

Why use plot-IT?

- Est since 1965

- Group turnover - £15 million

- 5 UK offices with over 100 staff

- HP Designjet Warranty Provider

- Autodesk Gold reseller

- Canon Elite Partner

- Stratasys - Gold Partner

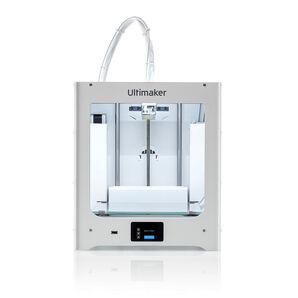

UltiMaker 2+ Connect 3D Printer (215810)

Click the yellow arrows to view multiple buying options...

-

Please contact us on 01905 454 598 for a quote

-

Description

UltiMaker 2+ Connect 3D Printer (215810): Effortlessly enter this new era by simply unboxing the printer, connecting three key components, and initiating your creative journey. The swift setup not only expedites your initial steps but also simplifies the process of installing multiple 3D printers, making scalability an effortless feat in the expansive landscape of innovative printing possibilities.

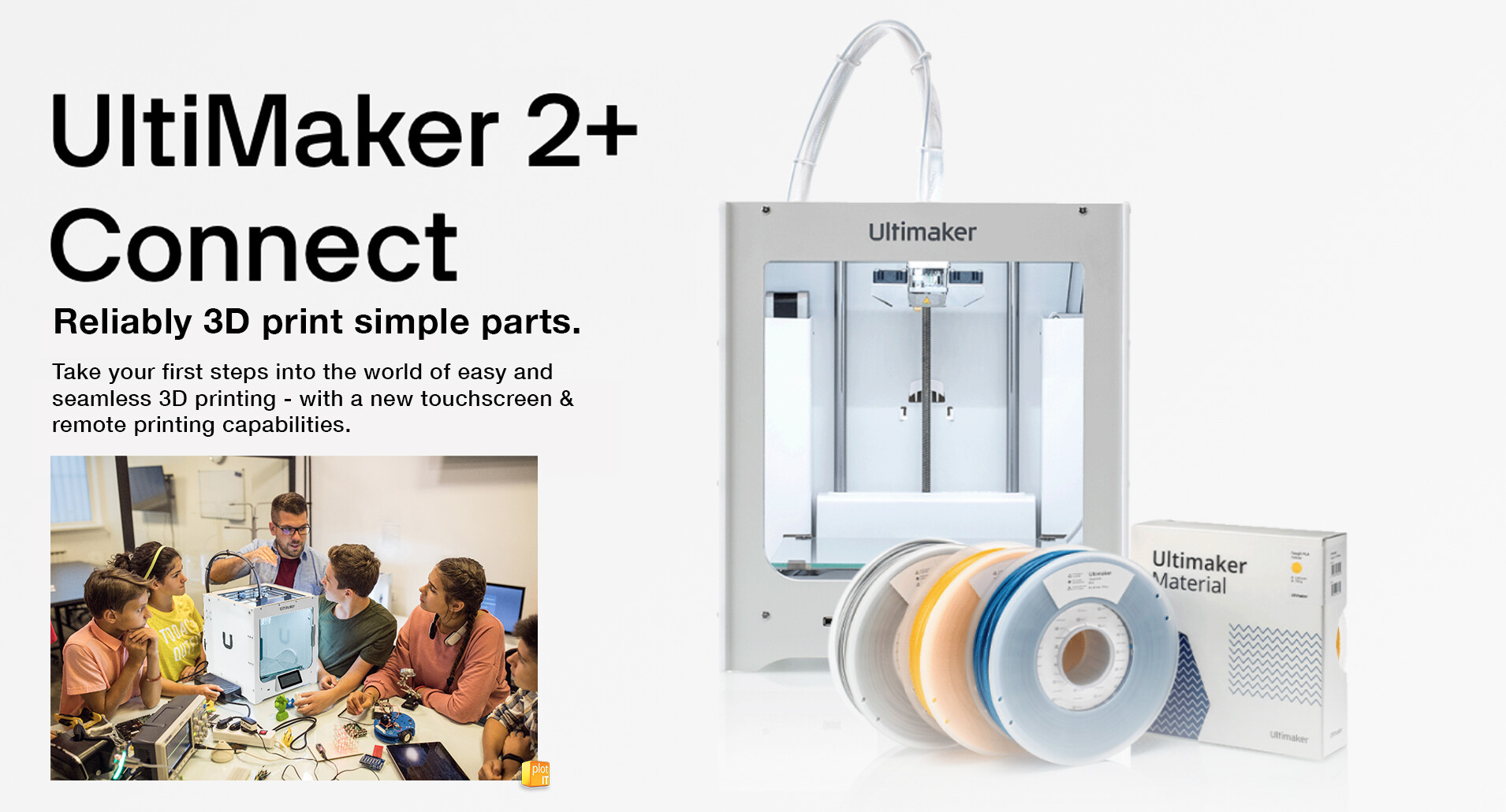

The Ultimaker 2+ Connect is your reliable first step into our world of easy, remote 3D printing. Featuring networking capabilities and a new touchscreen, the latest addition to the Ultimaker 3D printing portfolio will enable you to create a seamless 3D printing workflow that’s perfect for small enterprises and educators.

In the developmental stages, 3D printing serves as a catalyst, offering up to a 20x capability enhancement for iterating on new ideas and products. This transformative capability grants small enterprises unprecedented freedom and flexibility to experiment, fostering innovation. Additionally, by leveraging 3D printing to create prototypes using a variety of affordable materials, businesses can test their ideas without incurring exorbitant costs. On average, Ultimaker customers experience more than an 80% cost savings compared to outsourcing, making in-house 3D printing not just a technological advancement but a financially prudent strategy for bringing ideas to life.

MAIN FEATURES:

- START PRINTING QUICKLY: Install the printer in minutes

- EASY MAINTENANCE: Efficient design keeps maintenance needs to around 20 minutes per month

- WIDE MATERIAL CHOICE: With the Ultimaker open filament system, you can always find the right material

- TOUCHSCREEN: Effortless, intuitive operation via a touchscreen interface

- NEXT GEN COMPONENTS: Ergonomic feeder lever, stiffer build platform, and improved manual levelling

- NETWORK CONNECTIVITY: Via Wi-Fi or Ethernet, print remotely over the cloud with added security

- ENHANCED SAFETY: Add the Ultimaker 2+ Connect Air Manager (sold separately)

- ULTIMAKER ESSENTIALS: Unending access to security-assessed software – with remote printing, user management, and e-learning

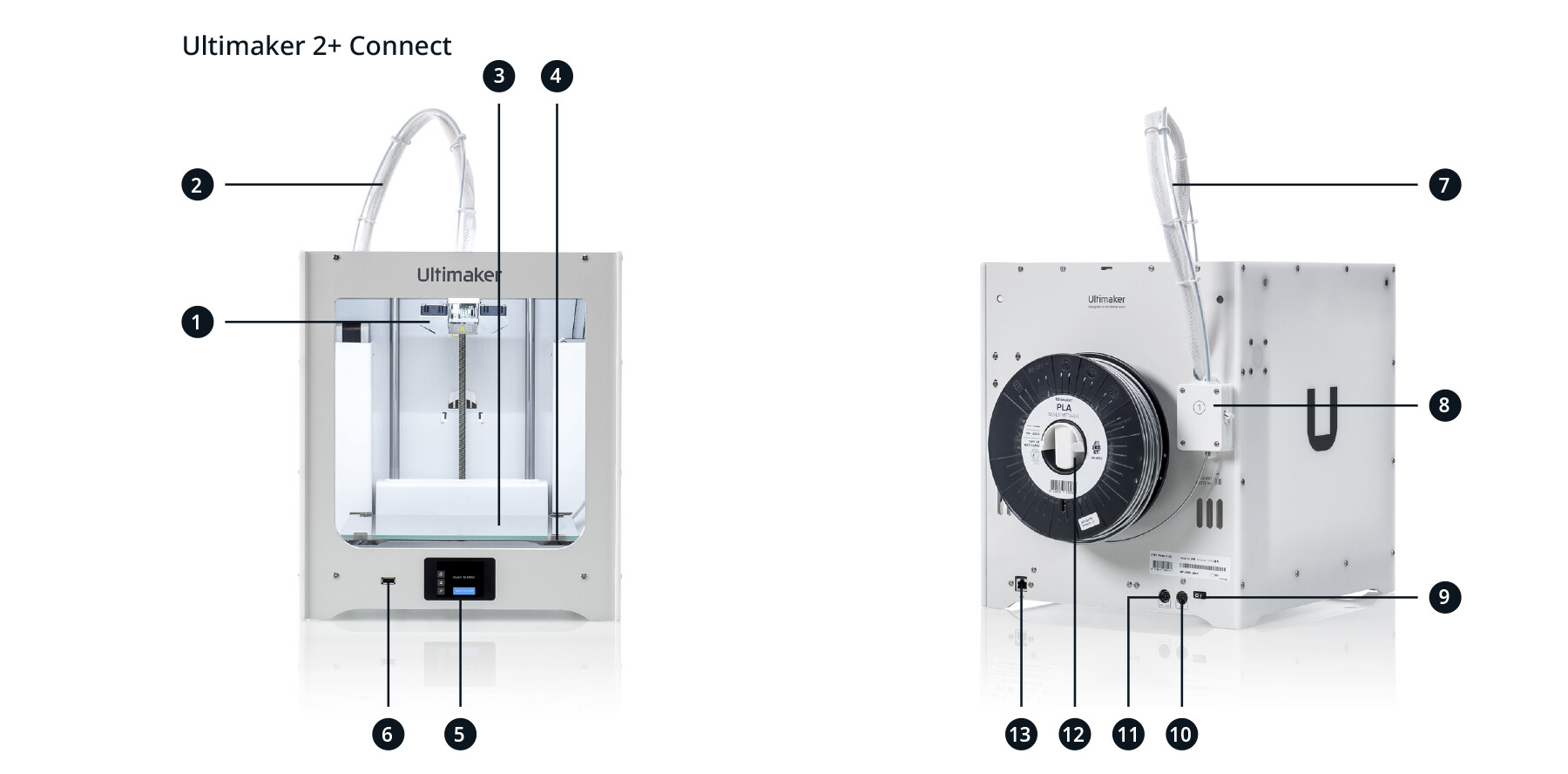

COMPONENT BREAKDOWN:

1. Print head 2. Print head cable 3. Build plate 4. Build plate clamps 5. Touchscreen display 6. USB port 7. Bowden tube 8. Feeder 9. On/off button 10. OUT port 11. Power socket 12. Spool holder 13. Ethernet port

Award-winning line of 3D printers stands as a testament to Ultimaker's robust, reliable, and user-friendly nature. These printers consistently deliver high-quality parts with unwavering precision. Meticulously designed and rigorously tested for continuous operation 24/7, they provide a seamless and efficient workflow, allowing you to achieve your desired results with speed and ease.

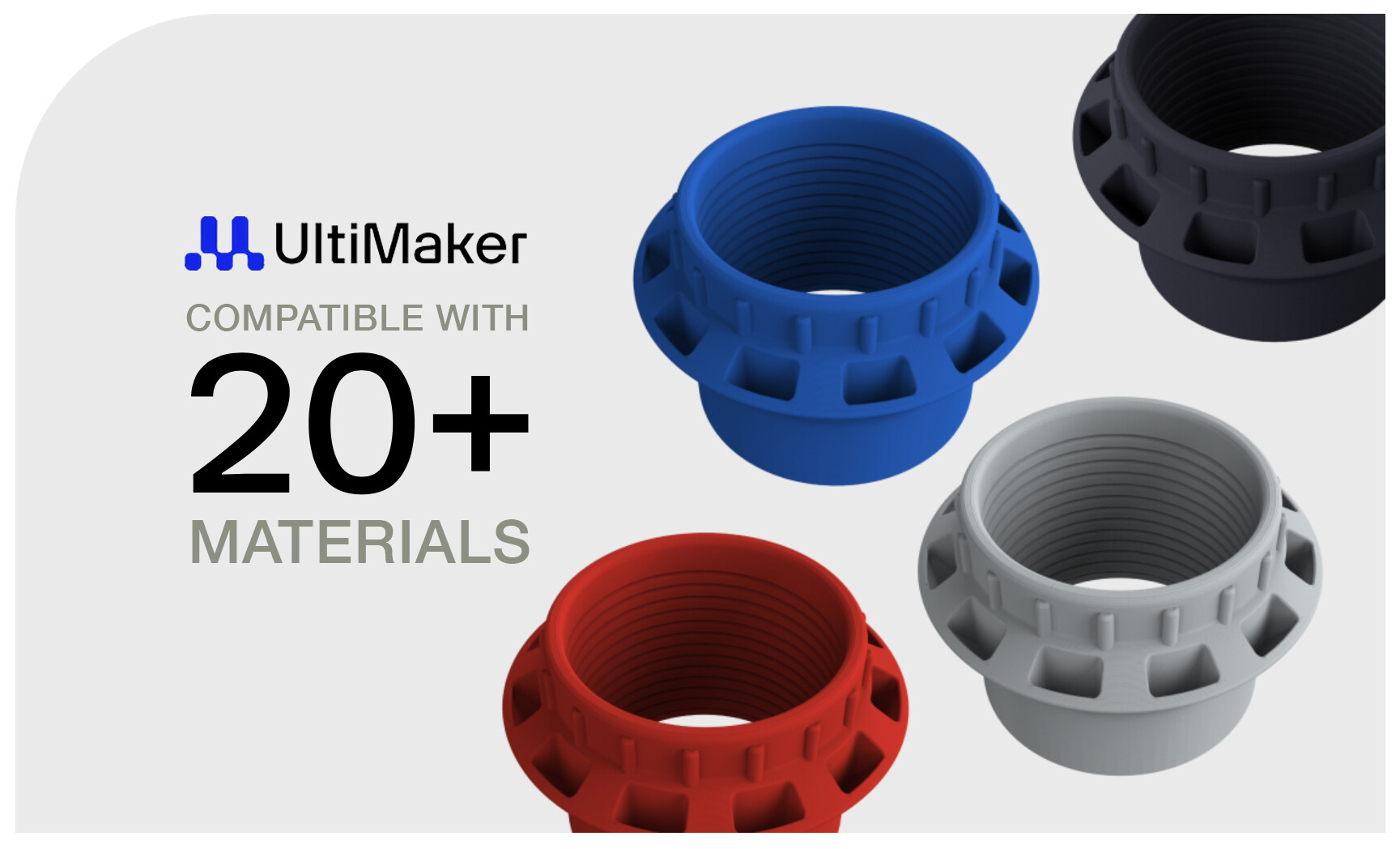

Featuring an open filament system, Ultimaker allows users to explore and select materials tailored precisely to their application needs. Whether seeking heat resistance, chemical resilience, wear resistance, or flexibility, Ultimaker's extensive material options empower users to fine-tune and optimize the properties of their prints.

Ultimaker Cura seamlessly integrates into any workflow, providing unparalleled flexibility through the utilization of Ultimaker Marketplace plugins. These plugins serve as dynamic extensions, allowing users to tailor their 3D printing processes to specific needs and preferences.

Ultimaker's extensive global network of service partners is dedicated to providing professional assistance, offering services such as installation, training, and maintenance in your preferred language and time zone. This ensures Ultimaker users around the world have access to localised support, making the experience of setting up, learning, and maintaining your 3D printer both convenient and tailored to your specific needs.

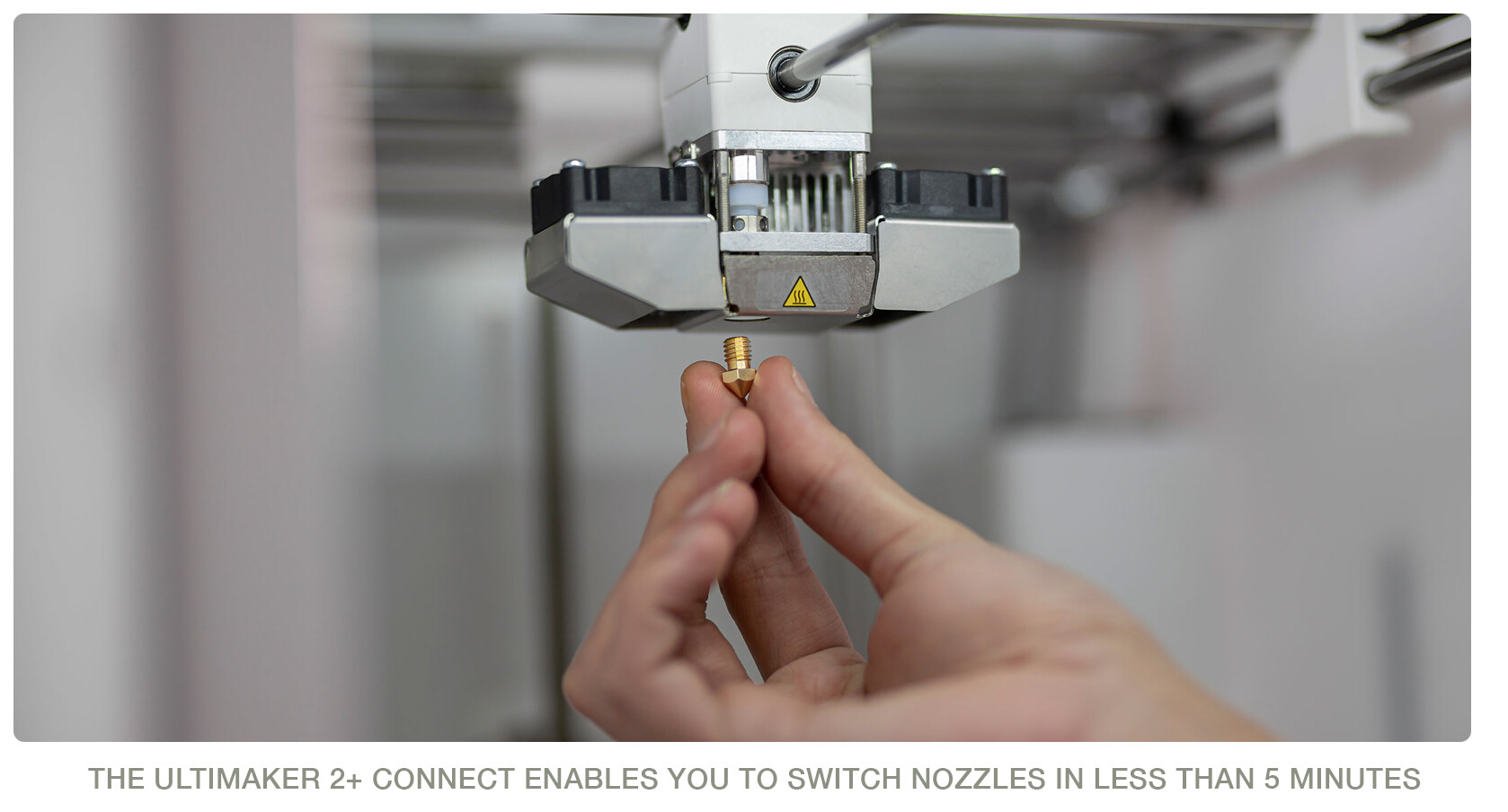

The UltiMaker 2+ Connect has a heater block with easily swappable nozzles. A 0.4 mm nozzle is already installed, and an extra 0.4 mm nozzle is included in the accessory box. Other compatible nozzle sizes include 0.25 mm, 0.6 mm, and 0.8 mm and can be purchased separately. Install a different nozzle size for faster prints, or to achieve more detail. To change the nozzle, use the 7 mm wrench that is included in the accessory box.

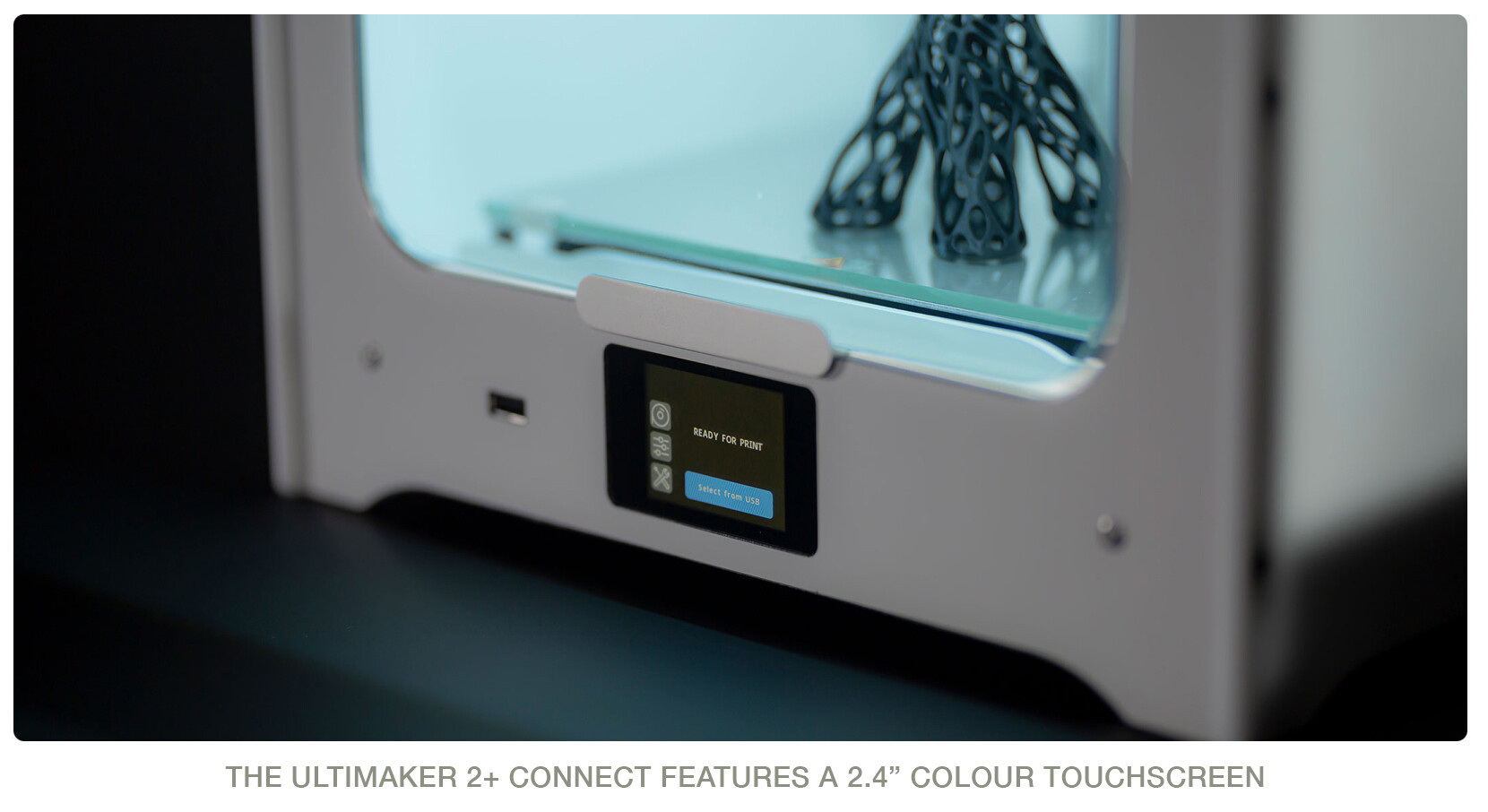

The 2.4" colour touchscreen accompanying our system provides an intuitive interface for seamless control and step-by-step guidance with every action. Whether you're changing materials, adjusting the build plate, or checking the status of your print, these operations are just a tap away. The user-friendly interface enhances the overall experience, offering a straightforward and interactive platform that empowers users to navigate through functions effortlessly, ensuring efficient and hassle-free 3D printing.

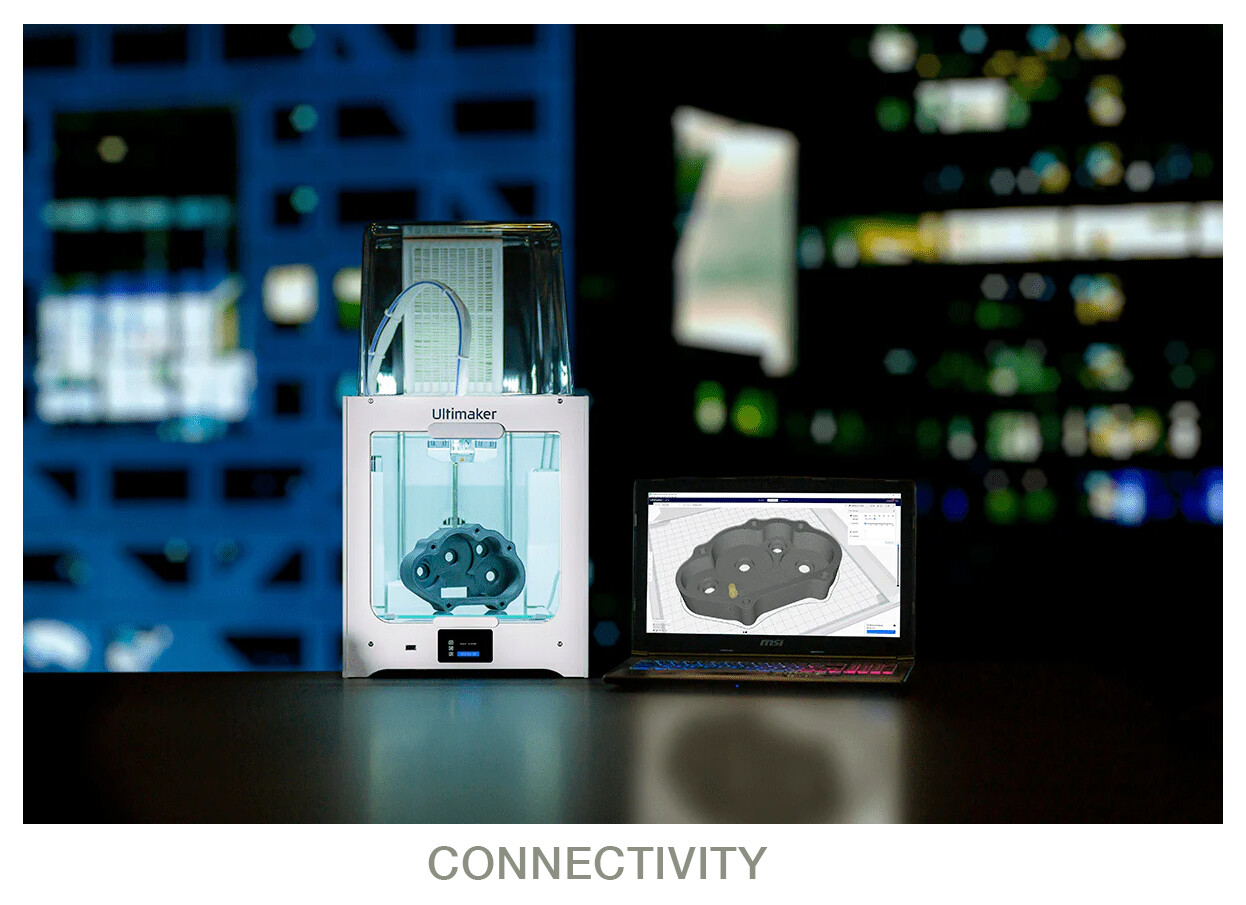

Connect the printer with Wi-Fi or an Ethernet cable and print remotely via cloud! The Ultimaker 2+ Connect printer can connect to a local area network using either Wi-Fi or Ethernet. To connect to the network, you can always navigate to the network setting on your printer to view network information or to set up a wireless connection. The printer will also prompt you to connect to a network during the welcome setup.

-

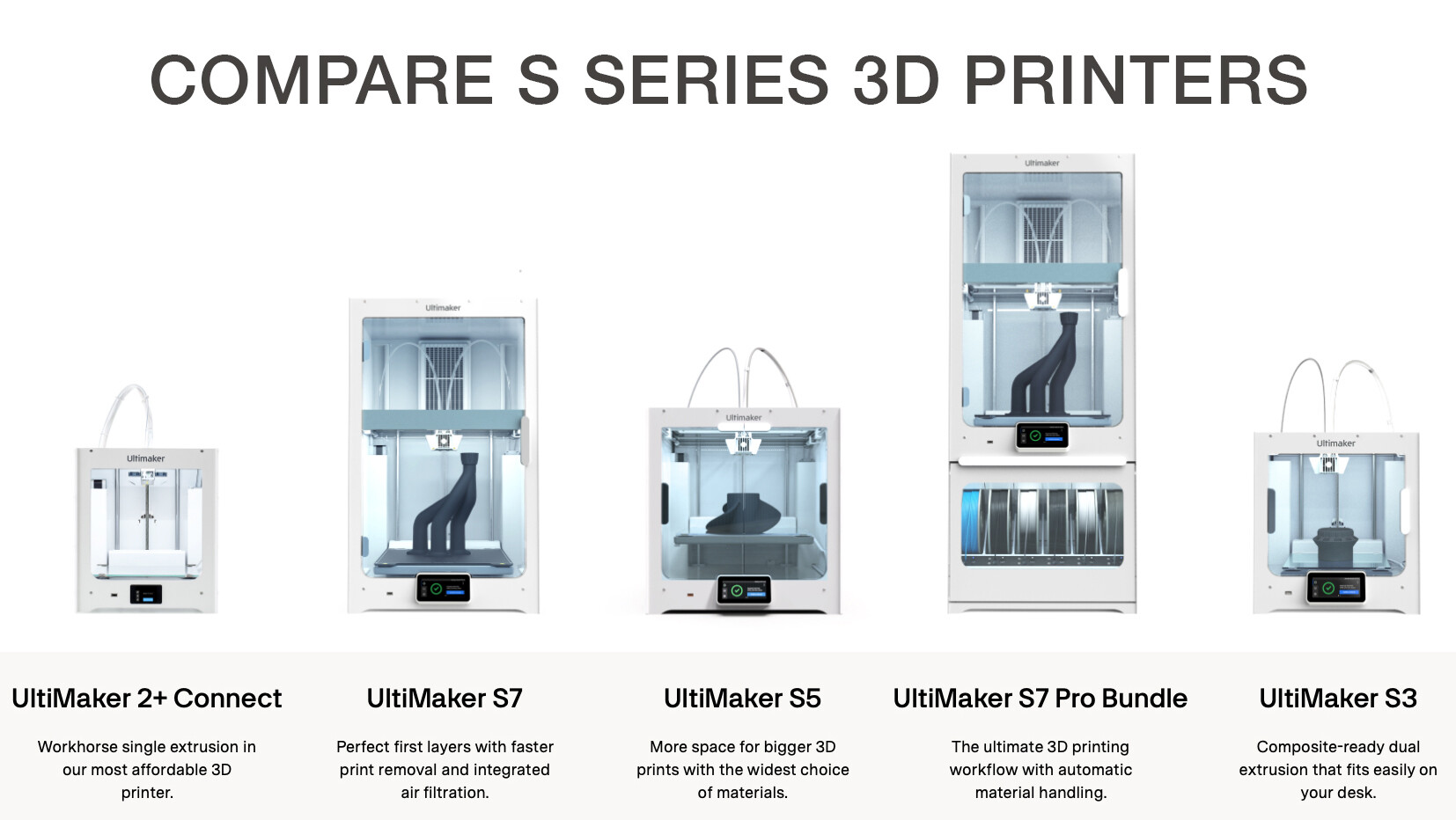

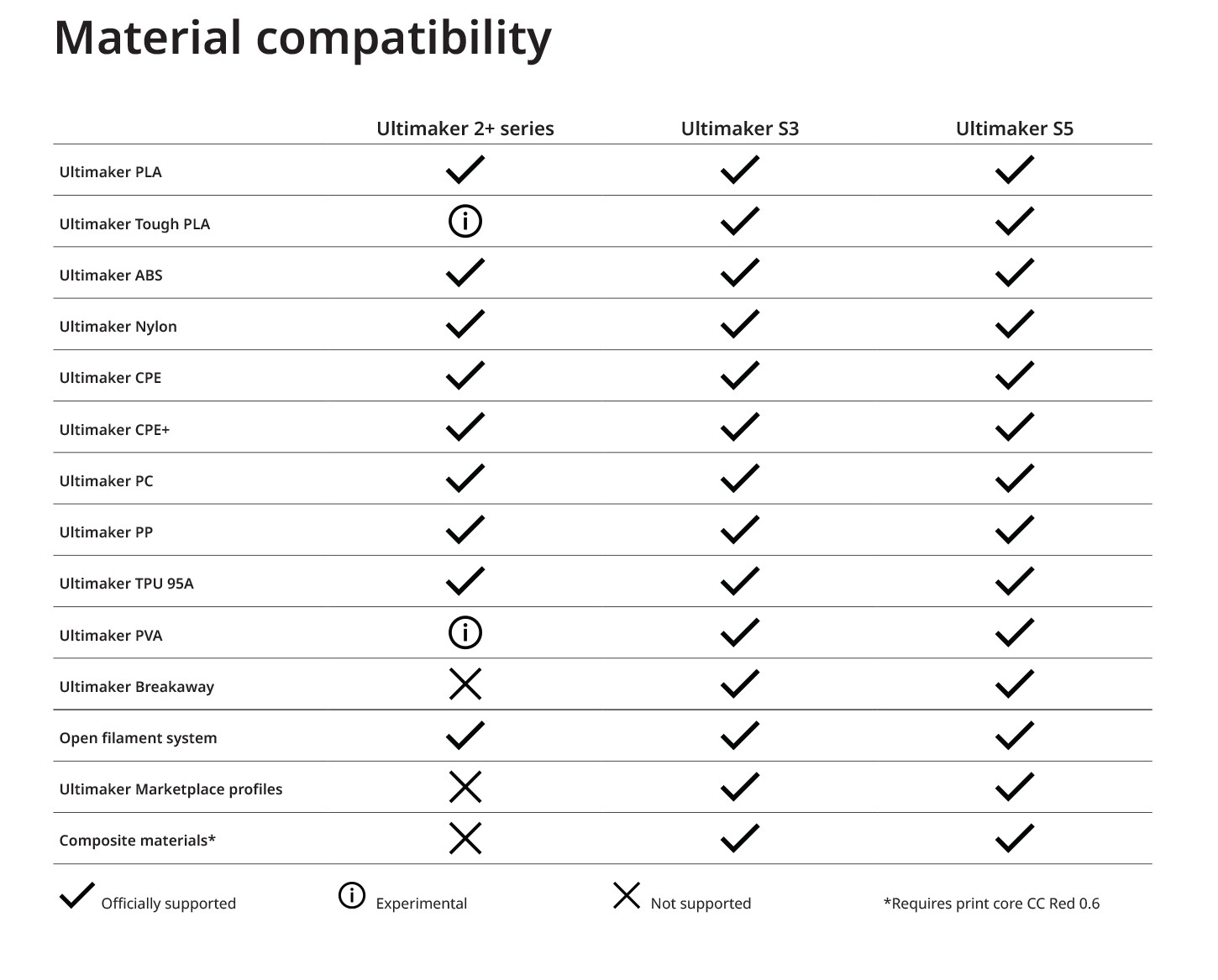

Material Compatibility Chart

-

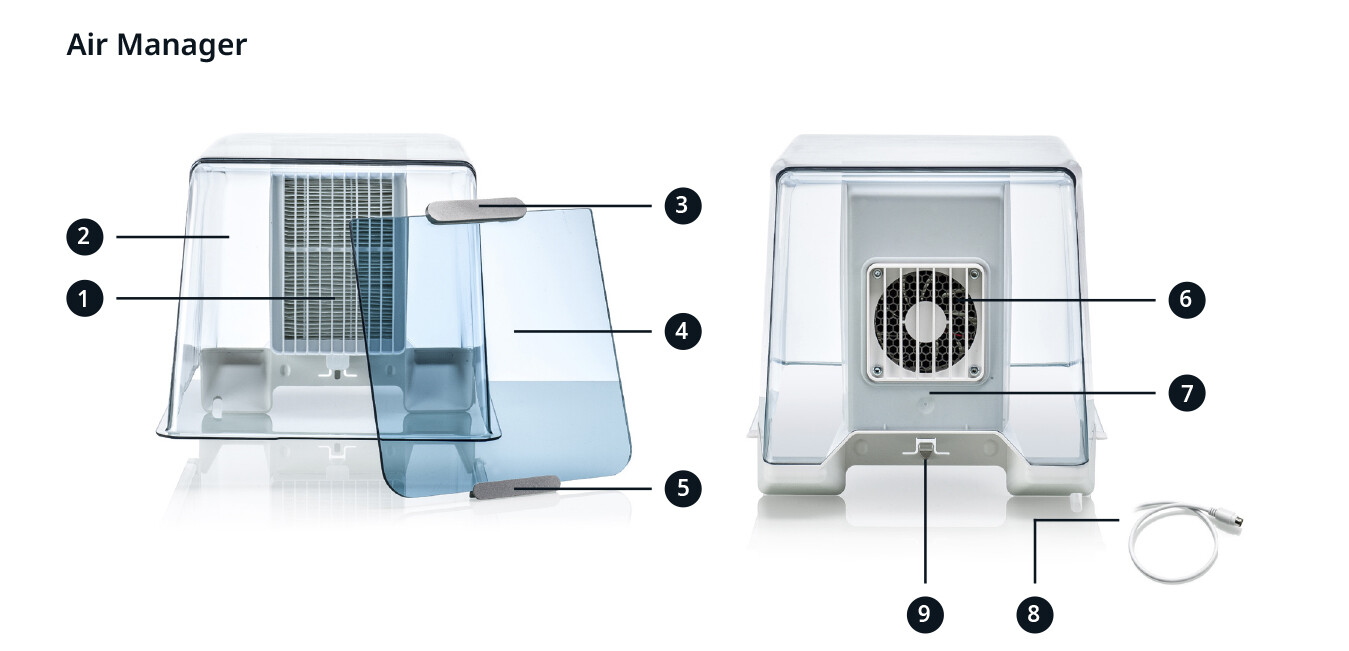

Ultimaker Air Manager (Optional)

The optional Ultimaker 2+ Connect Air Manager gives you more confidence and setup flexibility. Designed to simply and effectively increase user safety, it removes up to 95% of ultrafine particles (UFPs) and shields users from hot and moving components.

Enhance user safety effortlessly with the optional Ultimaker 2+ Connect Air Manager, a purpose-built solution designed for simplicity and effectiveness. Comprising the top cover, filter, and front enclosure, the Air Manager ensures a comprehensive approach to minimizing emission hazards associated with ultrafine particles (UFPs) from 3D printing materials.

1. Filter 2. Air Manager cover 3. Handle 4. Front enclosure 5. Hinge profile 6. Fan 7. Filter housing 8. Air Manager cable 9. Air Manager release clip

By using the Air Manager in conjunction with your Ultimaker 2+ Connect, you not only prioritise safety but also create a conducive environment for responsible and worry-free 3D printing. Highly recommended in classrooms, when printing with materials that emit significant amounts of UFPs, or in locations with multiple 3D printers.

-

Consumables

Unlock a wide range of applications with Ultimaker materials or use almost any 2.85mm filament available on the market.

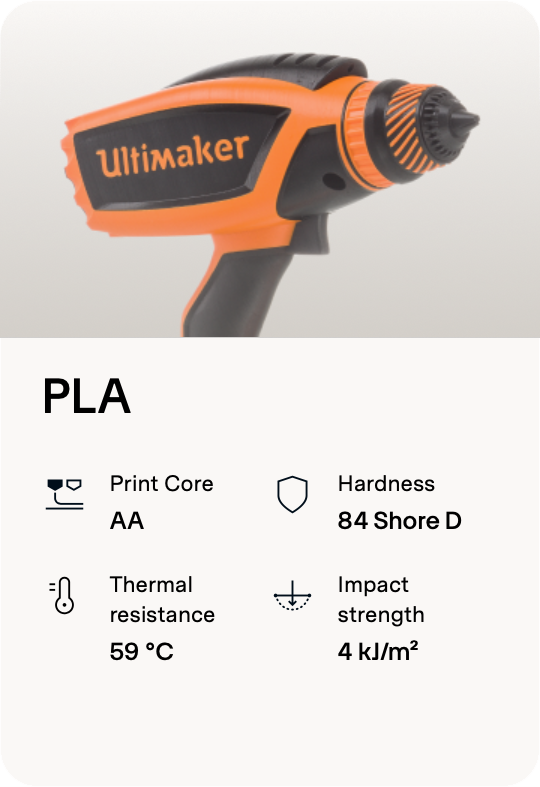

EASY TO PRINT:

Ultimaker PLA (750g)

- PLA - Green - 750g (1608)

- PLA - Black -750g (1609)

- PLA - Silver Metallic - 750g (1612)

- PLA - White - 750g (1613)

- PLA - Transparent - 750g (1614)

- PLA - Orange - 750g (1615)

- PLA - Blue - 750g (1616)

- PLA - Magenta - 750g (1617)

- PLA - Red - 750g (1618)

- PLA - Yellow - 750g (1619)

- PLA - Pearl White - 750g (1620)

Ultimaker Tough PLA (750g)

- Tough PLA - Black - 750g (202300)

- Tough PLA - White - 750g (202301)

- Tough PLA - Red - 750g (202302)

- Tough PLA - Green - 750g (202303)

- Tough PLA - Grey - 750g (202304)

- Tough PLA - Yellow - 750g (202305)

- Tough PLA - Blue - 750g (202306)

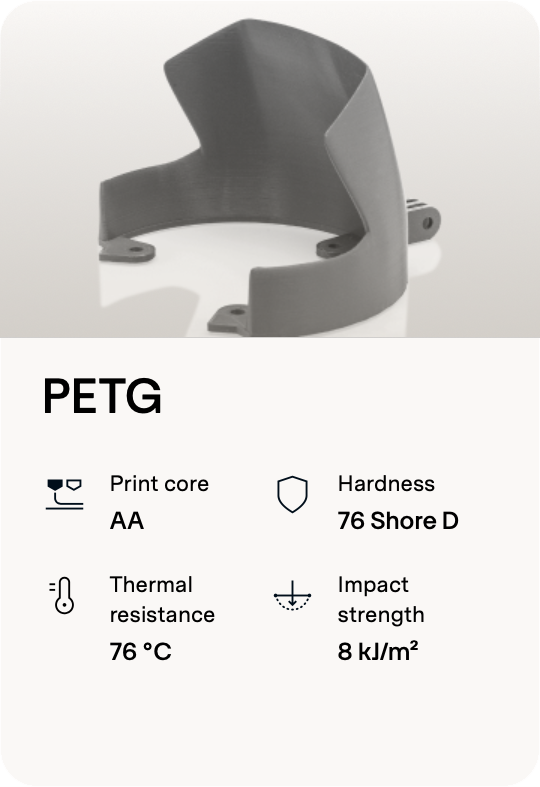

Ultimaker PETG (750g)

- PETG - Black - 750g (227282)

- PETG - White - 750g (227293)

- PETG - Silver - 750g (227326)

- PETG - Grey - 750g (227329)

- PETG - Green - 750g (227330)

- PETG - Transparent - 750g (227332)

- PETG - Blue - 750g (227333)

- PETG - Blue Translucent - 750g (227335)

- PETG - Red - 750g (227336)

- PETG - Red Translucent - 750g (227337)

- PETG - Green Translucent - 750g (227338)

- PETG - Yellow - 750g (227340)

- PETG - Yellow Fluorescent - 750g (227342)

- PETG - Orange - 750g (227343)

MECHANICAL STRENGTH:

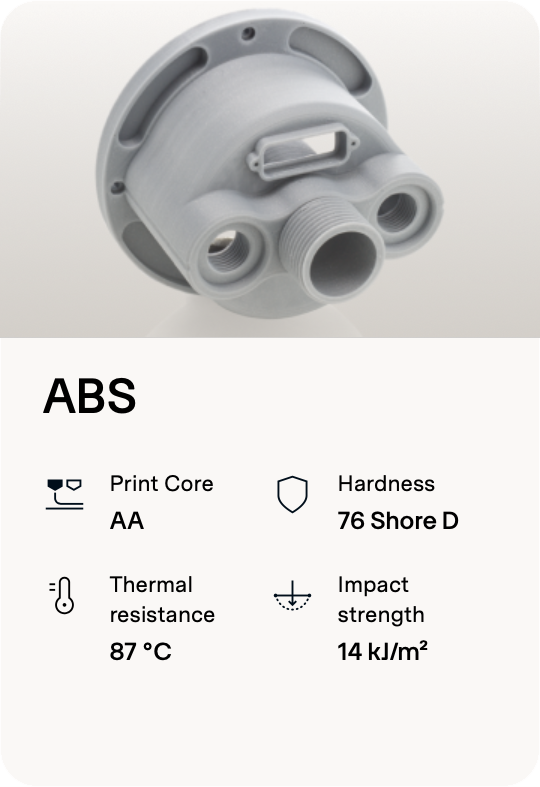

Ultimaker ABS (750g)

- ABS -Black - 750g (1621)

- ABS -White - 750g (1622)

- ABS -Red- 750g (1623)

- ABS -Blue- 750g (1624)

- ABS -Silver- 750g (1625)

- ABS -Pearl Gold - 750g (1626)

- ABS -Green - 750g (1627)

- ABS -Orange - 750g (1628)

- ABS -Yellow - 750g (1629)

- ABS -Grey - 750g (1630)

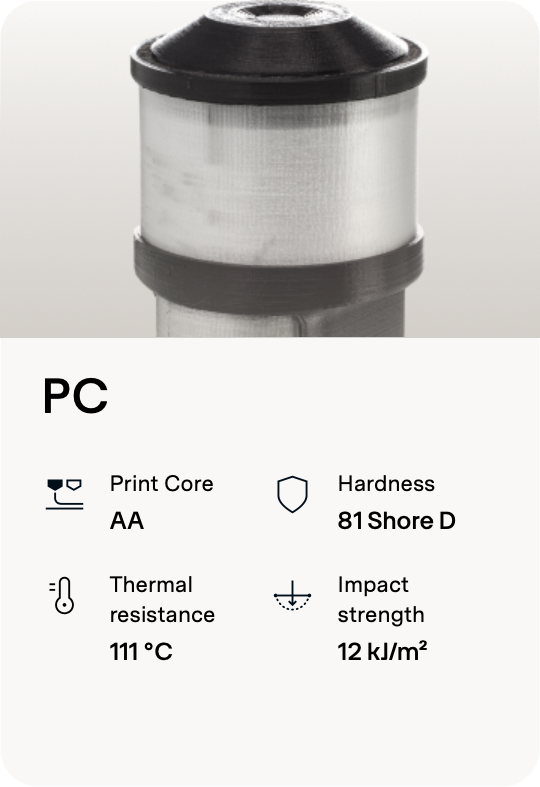

Ultimaker PC (Polycarbonate) (750g)

- Polycarbonate - Transparent - 750g (1640)

- Polycarbonate - Black - 750g (1641)

- Polycarbonate - White - 750g (1642)

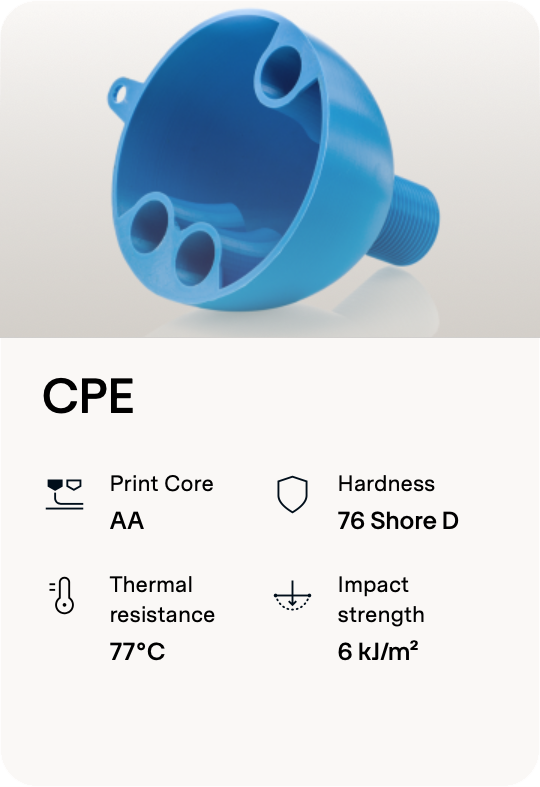

Ultimaker CPE (750g)

- CPE - Black - 750g (1631)

- CPE - White - 750g (1632)

- CPE - Light Grey - 750g (1633)

- CPE - Dark Grey - 750g (1634)

- CPE - Red - 750g (1635)

- CPE - Blue - 750g (1636)

- CPE - Yellow - 750g (1637)

- CPE - Green - 750g (1638)

- CPE - Transparent - 750g (1639)

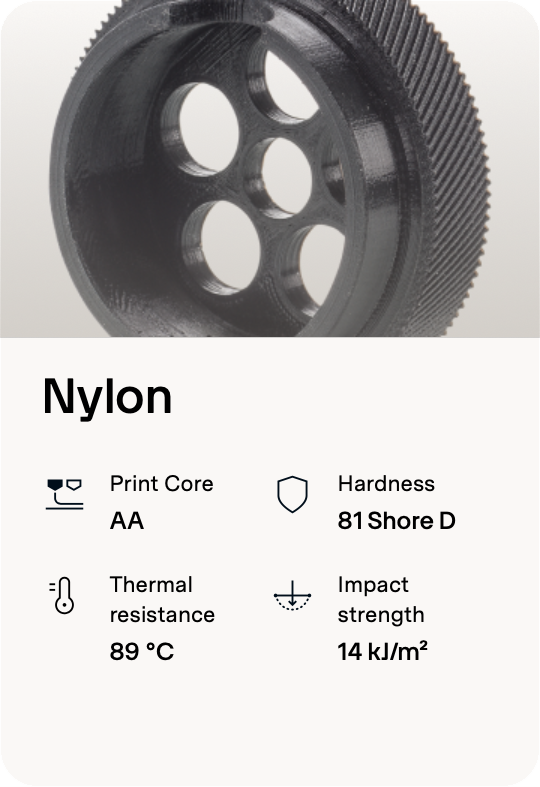

WEAR RESISTANCE:

Ultimaker Nylon (750g)

- Nylon - Black - 750g (1646)

- Nylon -Transparent - 750g (1647)

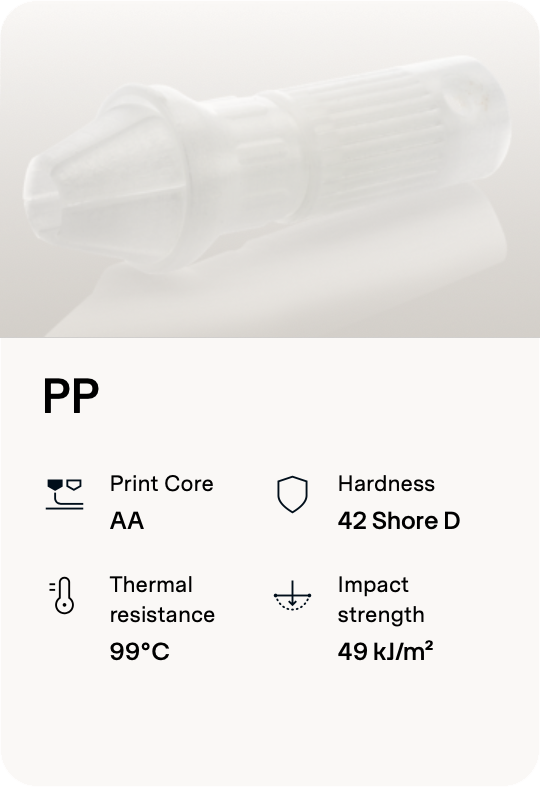

Ultimaker PP (500g)

- Polypropylene – Natural - 500g (1785)

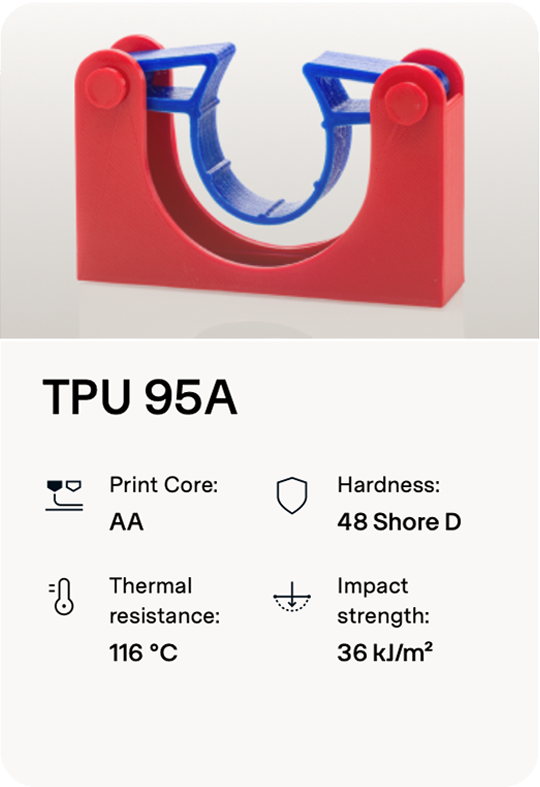

Ultimaker TPU 95A

- Ultimaker TPU 95A Blue Filament 700g (236593)

- Ultimaker TPU 95A Red Filament 700g (236590)

- Ultimaker TPU 95A White Filament 700g (236591)

- Ultimaker TPU 95A Black Filament 700g (236592)

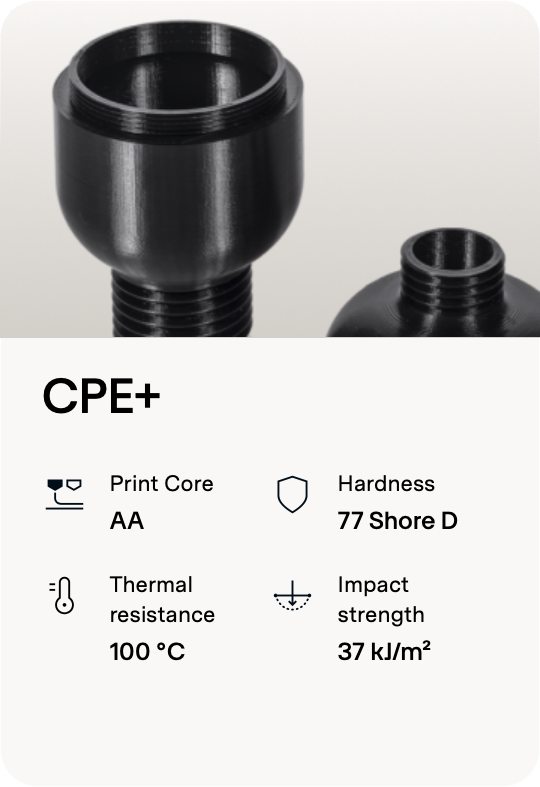

HEAT RESISTANCE:

CPE (co-polyester) materials stand out for their exceptional qualities, showcasing chemical resistance, toughness, and impressive dimensional stability. This makes CPE a preferred material for a wide range of applications, including both functional prototypes and mechanical parts. While both CPE and CPE+ share similar performance characteristics, CPE+ offers additional advantages. Notably, it boasts higher temperature resistance and increased impact strength, making it an excellent choice for applications where these specific attributes are crucial. Whether opting for CPE or CPE+, users can rely on these co-polyester materials to deliver durability and reliability in the creation of functional and robust 3D-printed components.

CPE VS CPE+

- CPE offers a diverse selection of colors, providing users with a broad palette to choose from. This includes the sophisticated greyscale option, which adds a professional touch to 3D-printed models.

- CPE exhibits notable strength with higher tensile and flexural strength. On the other hand, CPE+ takes toughness to the next level. Formulated to be up to 10 times tougher than standard CPE, CPE+ is engineered to provide enhanced durability and resilience.

- CPE+ features a temperature resistance of up to 100ºC when compared to CPE, which is only resistant up to 70ºC

Ultimaker CPE+

- Ultimaker CPE+ Transparent Filament 700g (1643)

- Ultimaker CPE+ Black Filament 700g (1644)

- Ultimaker CPE+ White Filament 700g (1645)

-

Training

Ultimaker 3D Printer training is available to cover all aspects of your new 3D printer including advanced level with the “Design for Additive” half day extension course, training is for up to 3 people on site with delivery of your new Ultimaker & we also run regular training courses at our Stoke Offices and for larger groups at our Worcester HQ , Bristol or Derby facilities.

INST002 INSTALLATION & TRAINING PACKAGES *

* INSTALLATION (IN CONJUNCTION WITH CUSTOMER):

Unboxing of printer and material station – connect units together Setup of Printer onto the network Setup of the printer into Cura and the Digital factory

* TRAINING (SOFTWARE & HARDWARE):

- Using Cura Slicing software to prepare parts for printing

- Cura setting

- Preview of time to print and cost to print

- Submitting prints

- Monitoring prints

- Loading and unloading of material on the printer

- Changing Cores

- Maintenance of the printer

- Tips and tricks

DfAM002 DESIGN FOR ADDITIVE (½ DAY) * & **

** DESIGN FOR ADDITIVE MANUFACTURING COURSE:

- Design rules for manufacturing

- Designing for FDM

- Exporting from CAD

- Orientation considerations

- Walls and Ribs

- Slice height and toolpaths

- Self-supporting designs

- Sectioning parts

- Assemblies / Moving parts

- Threads / Inserts

- Infills Tolerances

- Design samples discussed

- Various exercises to be completed though out the session

Download a Brochure

-

UltiMaker 2+ Connect 3D Printer (215810) Brochure

Download