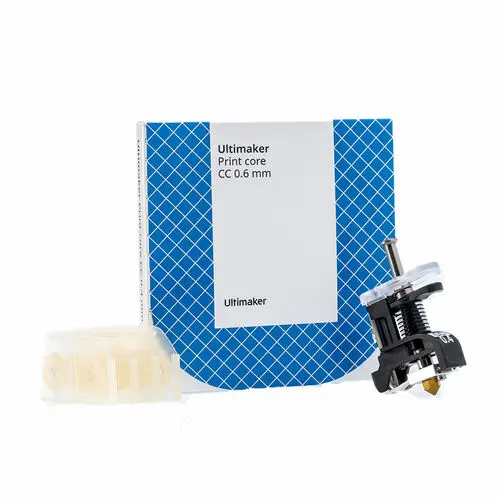

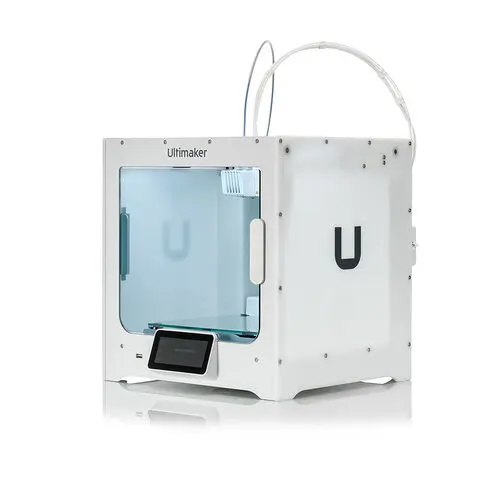

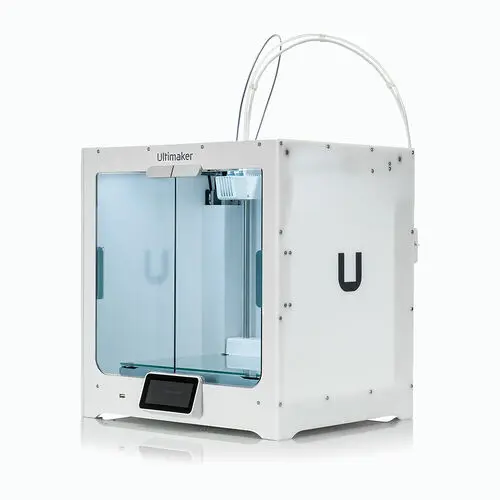

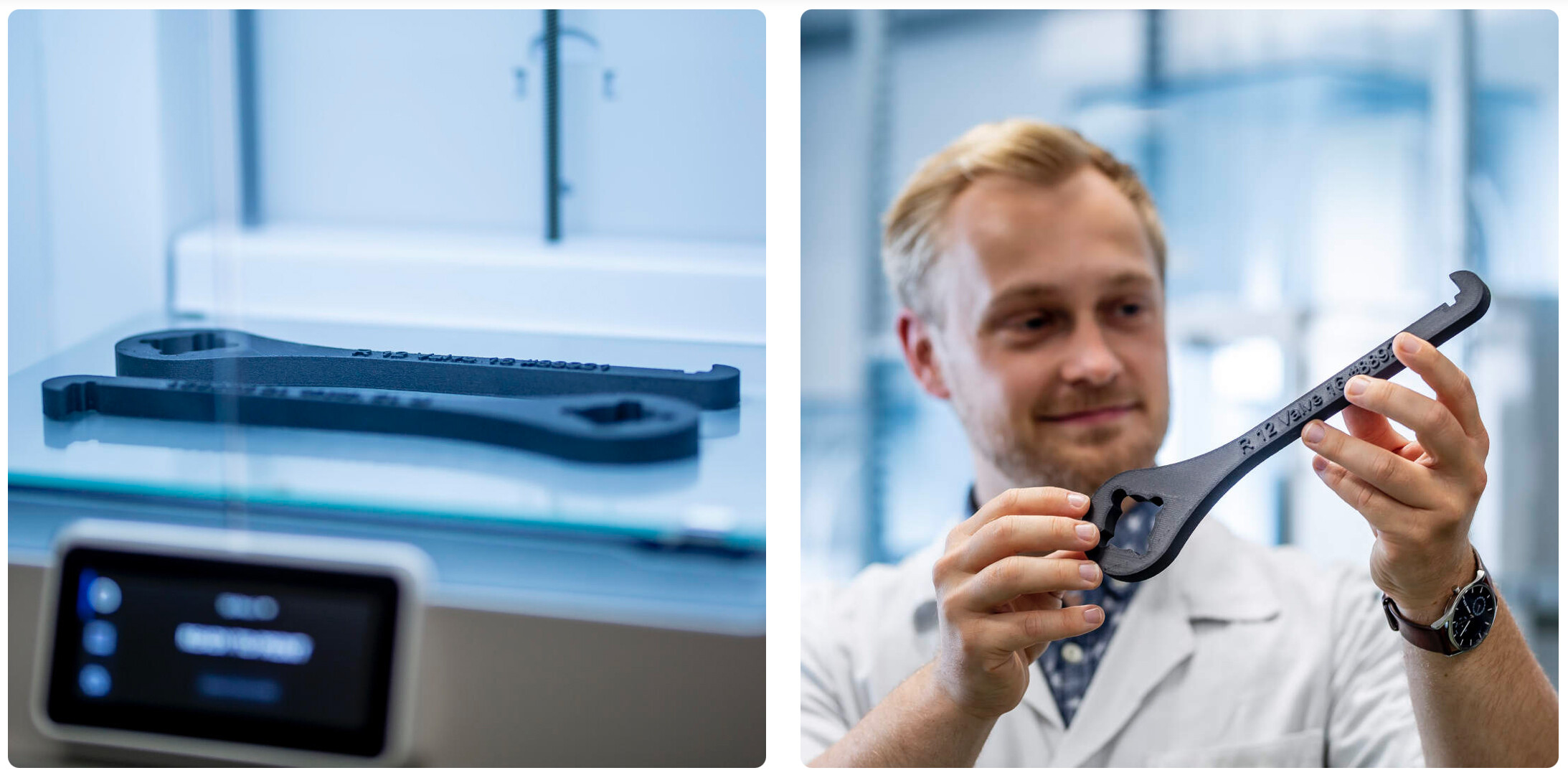

Ultimaker Print Core AA 0.8mm (9531): Tap into the potential of high-strength printing with the Ultimaker print core AA, compatible with a variety of composite materials available on the Ultimaker Marketplace. Featuring a durable, wear-resistant hardened steel nozzle and offering multiple sizes. Opt for 0.25mm or 0.4mm for superior visual precision or 0.8mm for faster print times with the added advantage of dual extrusion – enabling two-colour prints, or various material combinations with extra-fine detail.

The Print Core AA 0.8mm is a good option for high-speed printing. Using this print core, you can configure the layer height to be as much as 0.6mm, resulting in fewer layers and a significantly reduced printing speed. When using thicker layers, the layers will be more visible in the final print, so use this approach when the highest quality isn't needed.

MULTIPLE PRINT CORES, MAXIMUM FLEXIBILITY:

Three nozzle sizes – 0.25mm and 0.4mm, enabling you to print detailed parts, tools, or prototypes with higher visual quality, and 0.8mm, for shorter print times and improved efficiency – will result in easier optimisation of composite applications.

The Ultimaker print core AA 0.25's smaller nozzle size means your prints will feature extra fine levels of detail, thinner line widths, and a smooth surface finish when printing build materials including Nylon, PLA, CPE, ABS, TPU95A, Breakaway support and PP.

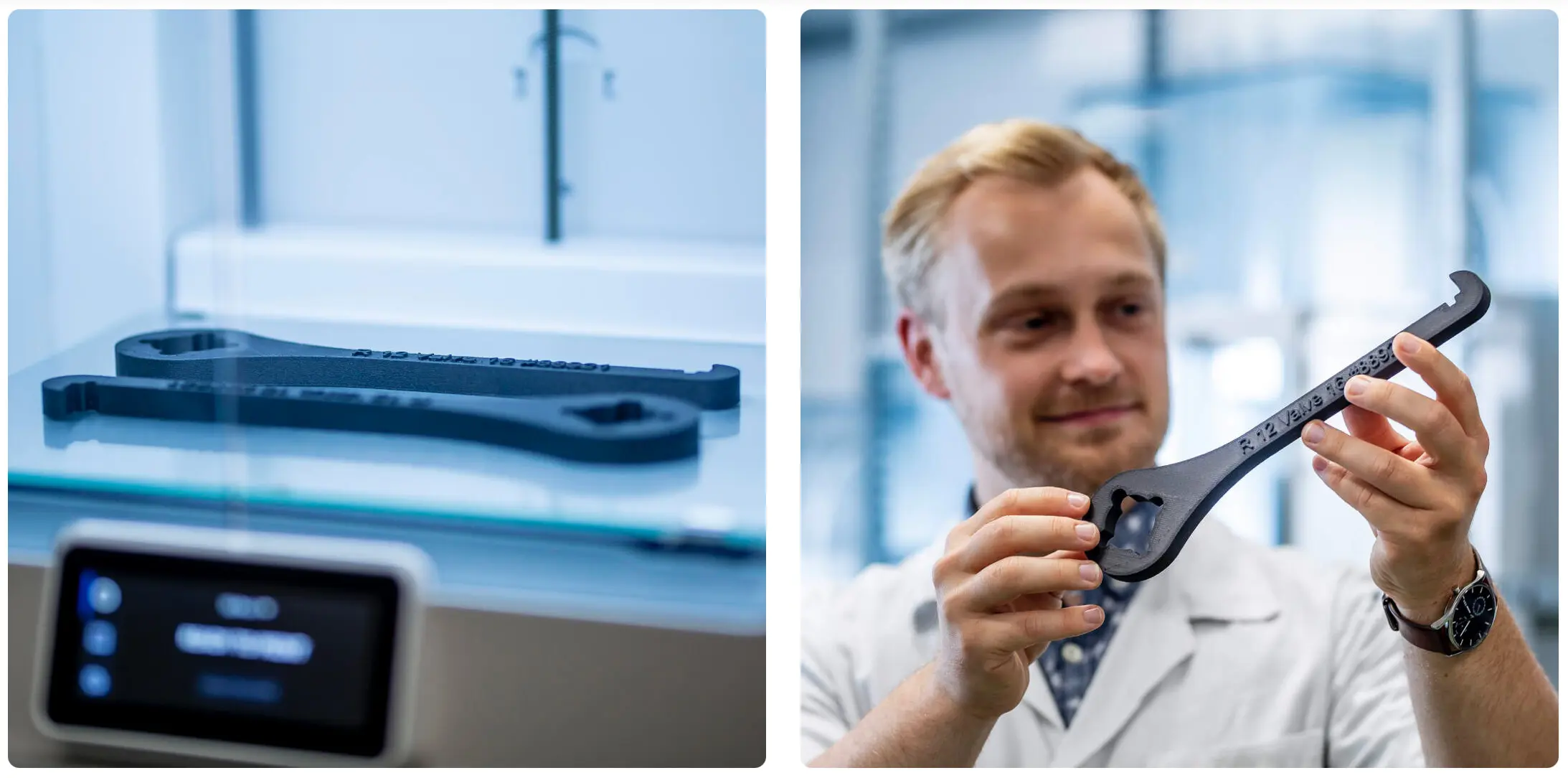

And by using the Ultimaker print core AA 0.8 to print with bigger line widths, your composite applications will be ready as quickly as possible – saving you time in a busy, hardworking environment that requires efficiency and speed.

RELIABLE, ROBUST, READY FOR WORK:

The Ultimaker print core AA features an all-new design with an abrasion-resistant, hardened steel nozzle and titanium heat break. Reliable, robust, and compatible with a wide range of composite 3D printing materials, you'll unlock the power to print high-strength applications that are ready for work.

QUICK SWAP – NO TOOLS NECESSARY:

With a quick-swap design, the Ultimaker print core AA – like all Ultimaker print cores – can be quickly and easily changed, tool-free, to meet the requirements of any print job, increasing your efficiency and decreasing downtime.

Plus, the print core's EEPROM chip memorises the size and type of your nozzle, meaning fewer printing errors and an increased chance of success.