- CAD Plotters

- Wide-Format Photo, Fine Art & Graphic Printers

- HP Latex, Outdoor, Signage, Wall Paper Printers & Cutters

- Wide Format Ink & Media Supplies

- Multi Functional Printers & Plan Copiers

- Large Format Scanners

- Finishing - Large Format Paper Folders, Trimmers, XY Cutters & Laminating

- Canon A4 and A3 Copier Paper

- Canvas, Stretcher Bars & Laminate

- Fabric Printers

- 3D Printers

- Bricsys BricsCAD® Software

- Colour Management & RIP Software

- Plotter Warranties

- Storage & Filing Systems

- OFFERS

Why use plot-IT?

- Est since 1965

- Group turnover - £15 million

- 5 UK offices with over 100 staff

- HP Designjet Warranty Provider

- Autodesk Gold reseller

- Canon Elite Partner

- Stratasys - Gold Partner

Ultimaker Print Core DD 0.4mm (9550)

-

Description

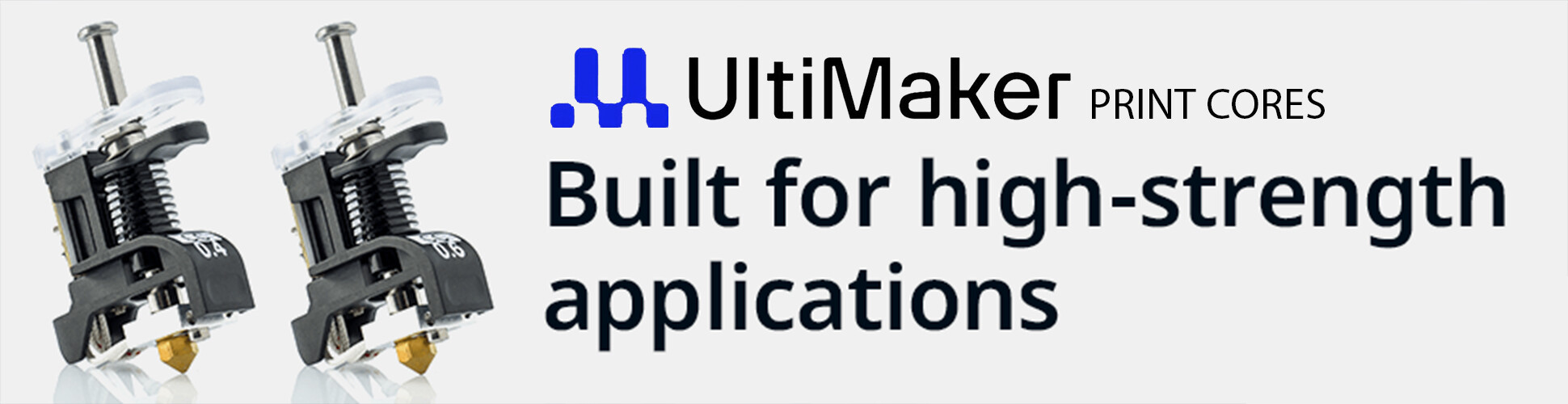

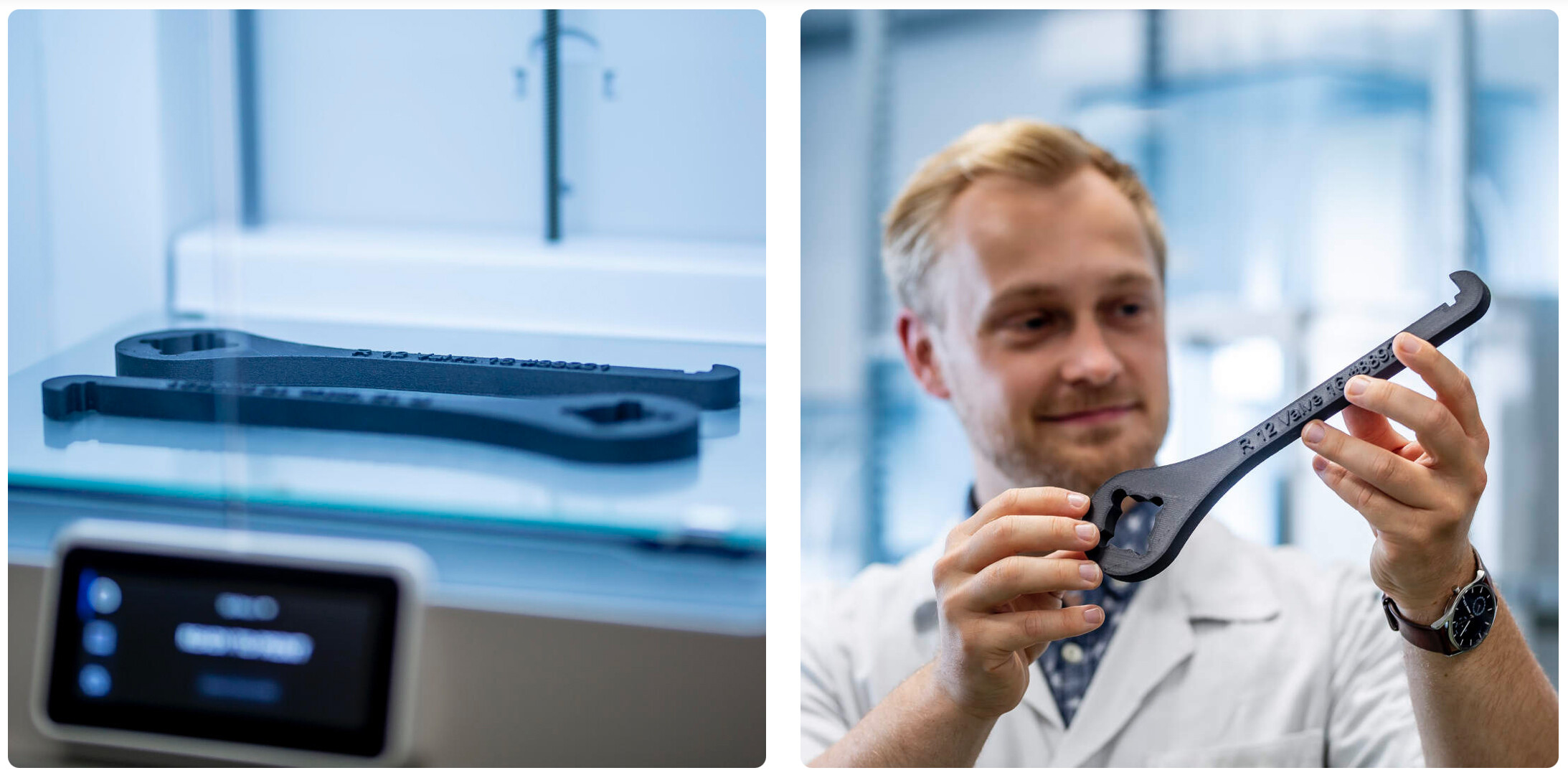

Ultimaker Print Core DD 0.4mm (9550): The print core DD 0.4 is specially designed for printing support interface layers in combination with metal materials on S series printers. This print core is optimised to withstand abrasive materials, such as the ceramic support layer filament used for metal FFF printing.

The DD print cores are used for Ultrafuse® Support Layer material. This print core is included in the UltiMaker Metal Expansion Kit and can also be purchased separately. Requires UltiMaker Cura version 5.1 or later, and S series firmware 7.0.4 or later.

The DD print core is compatible with S series printers, including the UltiMaker S3, UltiMaker S5, and UltiMaker S7. These printers are prepared for printing abrasive materials; the knurled wheels in the S series feeders are made of a hard material with a special coating to minimise wear due to composite materials.

Note that the DD core is specifically intended for Ultrafuse® Support Layer material. This is NOT supported in combination with a Material Station.

It is recommended to use an Air Manager while printing Ultrafuse® 17-4PH and Ultrafuse® Support Layer materials. The Air Manager is an integrated component of the UltiMaker S7 and an optional add-on for the UltiMaker S5.

MAINTENANCE:

Due to the material properties of Ultrafuse® Support Layer, more frequent maintenance is required for the DD core than for other print cores. For the DD core, it is recommended to clean it using the hot and cold pull method after each print, unless another print job is started again immediately. Always clean the print core if it will not be used again for a longer period of time, or before unloading it from the print head.

UltiMaker S-Series Cleaning Filament (20cm strips x 10) (2297) infos can be found HERE.

-

Print Core Compatibility

PRINT CORE TYPE COMPATIBLE MATERIAL TYPES AVAILABLE SIZES COMPATIBLE PRINTERS AA Build materials and Breakaway support 0.25mm

0.4mm

0.8mmUltimaker 3

Ultimaker S3

Ultimaker S5

Ultimaker S6

Ultimaker S7

Factor 4BB Water-soluble (PVA) support material. On the S8, also used for Breakaway support 0.4mm

0.8mmUltimaker 3

Ultimaker S3

Ultimaker S5

Ultimaker S6

Ultimaker S7

Ultimaker S8

Factor 4CC Composite (glass or carbon-filled) materials 0.4mm

0.6mmUltimaker S3

Ultimaker S5

Ultimaker S6

Ultimaker S7

Factor 4DD* Ultrafuse Support Layer material (Metal Expansion kit) 0.4mm Ultimaker S3

Ultimaker S5

Ultimaker S6

Ultimaker S7

Factor 4HT High-temperature materials such as UltiMaker PPS CF 0.6mm Factor 4 AA+ High-flow, high-speed printing with (non-composite) build materials 0.4mm Ultimaker S5

Ultimaker S6

Ultimaker S7

Ultimaker S8CC+ High-flow, high-speed printing with composite materials 0.4mm Ultimaker S5

Ultimaker S6

Ultimaker S7

Ultimaker S8*The DD print core and Ultrafuse Support Layer material are only available in selected regions.

COMPATIBILITY EXPLANATION:

The AA and BB print cores are compatible with all UltiMaker printers that use print cores (UltiMaker 3, S series, and Factor 4). These print cores are not intended for use with abrasive materials.

The CC print cores are only compatible with UltiMaker printers with abrasion-resistant feeders (S series and Factor 4). These print cores are intended for use with abrasive or composite materials. These print cores cannot be used on the UltiMaker 3, because the UltiMaker 3 feeders are not compatible with composite materials.

See more information about the AA and CC cores on the UltiMaker S8 below.

The CC print cores can also be used in combination with the Material Station. The Material Station has abrasion-resistant prefeeders in all material bays. However, the Material Station is not compatible with all composite materials. Please check the latest profiles in the UltiMaker Marketplace to determine if the material can be used with the Material Station.

The DD cores are not recommended for use with the S series Material Station. The DD print cores currently only support Ultrafuse Support Layer filament, which is used when printing metal. This is not recommended with the S series Material Station due to the curves in the internal filament path. On Factor 4, the filament path is different (smoother) so this does not affect the Ultrafuse material as much.

The HT print cores are only compatible with Factor 4. This print core type is optimized for high-temperature materials, such as UltiMaker PPS CF. This material requires a high printing and build volume temperature to print reliably; only Factor 4 features a heated build chamber.

The AA+ and CC+ print cores feature redesigned nozzles optimised for faster material melting and deposition, ensuring seamless compatibility with UltiMaker Cheetah motion planning. This advanced motion planner is exclusive to the UltiMaker S8.

Regular AA and CC print cores can be used on the S8, but this workflow is not fully supported. These cores are not designed for the high-speed capabilities of the S8. The AA and CC cannot be selected for S8 in Cura; no profiles are developed for this configuration. To use the regular AA and CC cores on the S8, you can slice the print job for UltiMaker S7 instead and print it on S8.

-

When, Why & How to use Cleaning Filament

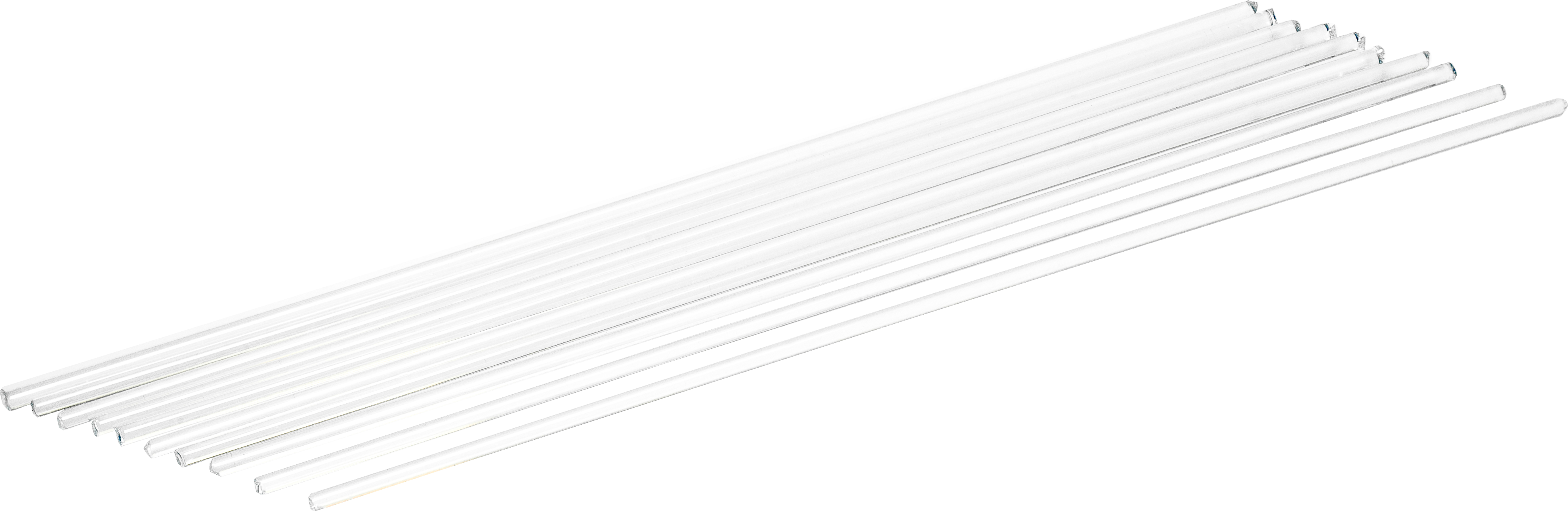

UltiMaker S-Series Cleaning Filament (20cm strips x 10) (2297): UltiMaker cleaning filament is a pack of precut, straightened pieces of material. They are ideal for cleaning the inside of the print cores and removing any blockages. It is the most effective material for the hot and cold pull procedure. This pack of ten 20 cm long cleaning filament pieces to ensure your Ultimaker print cores are always in optimal condition. Especially effective for cleaning a print core BB.

WHY USE CLEANING FILAMENT:

Cleaning filament are sticks of 2.85 mm material. These sticks are straight, for easy insertion into the print head during the hot and cold pull procedure. They are precut to an optimised length. One stick of cleaning filament is easy to handle and is sufficient to clean one severely blocked print core, or even multiple cores with minor blockages.

UltiMaker cleaning filament is transparent polycarbonate (PC) material. If you need to learn more about the material specifications, please take a look at the UltiMaker PC safety data sheet.

The cleaning filament sticks are optimised for easy handling. Also, this material (PC) is most effective for clearing any blockages inside the print core and removing any material residue left inside the nozzle. You can also use other materials, such as PLA, for cleaning the print core by cutting off a length from the spool of filament, but this may not be as effective or efficient.

WHEN TO USE CLEANING FILAMENT:

You can use cleaning filament both as preventive and corrective maintenance. It is recommended to apply preventive maintenance to the print cores. This is based on a number of printing hours or prints, depending on the type of print core.

UltiMaker print cores should be cleaned periodically for optimal print results. Material can sometimes get stuck inside the nozzle and degrade. This can cause extrusion problems, or even completely block the print core. Some materials are more prone to degradation and blocking the nozzle, such as PVA and composite materials. To prevent problems, you can perform the print core cleaning procedure according to the recommended maintenance schedule below:

PRINT CORE TYPE: RECOMMENDED CLEANING FREQUENCY: Print Core AA No scheduled preventive maintenance required. Note that cleaning the print core is recommended when switching to a material with a very different printing temperature. Print Core BB Every three months, or ~ 400 printing hours. Print Core CC Every month, or ~ 100 printing hours. Note that when printing metal filaments, it is recommended to clean the print cores after every print for the highest reliability. Print Core DD After every print, or when the print core is not going to be used for > 24 hours. Using the UltiMaker cleaning filament is the most effective way to clean and unclog print cores. If you do not have UltiMaker cleaning filament at your disposal, you could use PLA instead.

HOW TO USE CLEANING FILAMENT:

This filament can be used to clean the print cores of the UltiMaker 3 and S series by applying hot and cold pulls. Hot pulls are used to get the biggest parts of carbonized material out of the print core and are highly recommended when the print core is clogged. With a cold pull, the remaining small particles will be removed, ensuring the print core is completely clean.

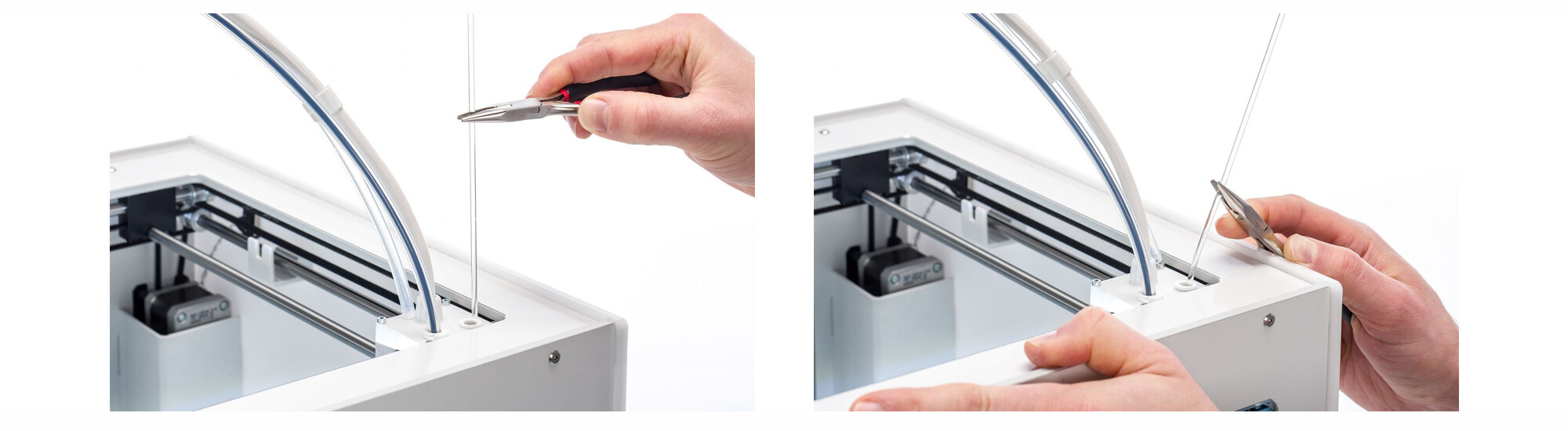

The UltiMaker 3 and S series printers contain a guided process for cleaning the print cores. You will need a stick of cleaning filament and a pair of pliers. Detailed instructions on how to perform the hot and cold pull procedure with UltiMaker cleaning filament can be found HERE.

PRINTER COMPATIBILITY:

UltiMaker cleaning filament is intended and optimized for cleaning the print cores. This means it is officially compatible with the UltiMaker S series (including S7, S5, and S3) and the UltiMaker 3 series (including the 3 and 3 Extended).

However, the cleaning filament sticks can also be used to apply a similar cleaning process for the nozzles of other UltiMaker printers, including the UltiMaker 2+ Connect, 2+ series, 2 series, and even the Original. Note that these printers do not have a guided cleaning procedure built into the firmware, but you can set the temperatures manually. Cleaning filament requires a high temperature, so set the nozzle temperature to 260 °C.

**Note: UltiMaker cleaning filament is not compatible with the Method, Sketch, and Replicator series printers, as these are designed for 1.75 mm filament.**