- CAD Plotters

- Wide-Format Photo, Fine Art & Graphic Printers

- HP Latex, Outdoor, Signage, Wall Paper Printers & Cutters

- Wide Format Ink & Media Supplies

- Multi Functional Printers & Plan Copiers

- Large Format Scanners

- Finishing - Large Format Paper Folders, Trimmers, XY Cutters & Laminating

- Canon A4 and A3 Copier Paper

- Canvas, Stretcher Bars & Laminate

- Fabric Printers

- 3D Printers

- Autodesk Subscription & HP CAD Workstations

- Colour Management & RIP Software

- Plotter Warranties

- Storage & Filing Systems

- OFFERS

Why use plot-IT?

- Est since 1965

- Group turnover - £15 million

- 5 UK offices with over 100 staff

- HP Designjet Warranty Provider

- Autodesk Gold reseller

- Canon Elite Partner

- Stratasys - Gold Partner

Canon IJM667 Scrim Banner Light, Matt M1 (Black Back) 325g/mē 97001283 63" 1600mm x 25m roll **LATEX / UV (GEL) / (ECO) SOLVENT**

-

Please contact us on 01905 454 598 for a quote

-

Description

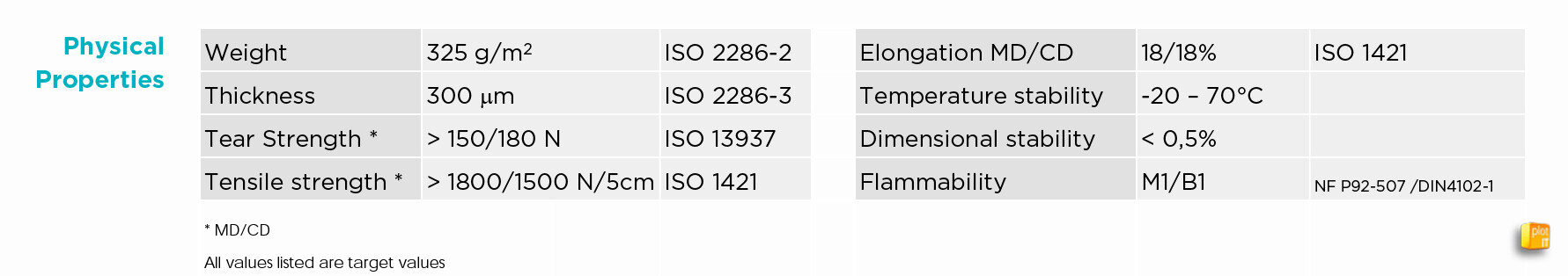

Canon IJM667 Scrim Banner Light, Matt M1 (Black Back) 325g/m²: High-quality, ultra flat, white scrim banner with M1 certification. The black reverse side offer full opacity together with a distinct look. This media has fantastic dimensional stability with no curling and is suitable for indoor and outdoor banners and high quality displays. Optimised for use with latex (eco) solvent and UV (gel) printers.

APPLICATIONS:

- High-quality displays

- Roll-ups

- Point of sale

- Indoor/outdoor banners

FEATURES:

- Fire retardant M1/B1

- Smooth, high-quality matt surface

- Opaque black coating on the reverse side

- Ultra flat, does not curl

- 3" core

-

Other available sizes

Canon | IJM667 | Scrim Banner Light, Matt M1 (Black Back) 325g/m² | 97001282 | 900mm x 25m roll

Canon | IJM667 | Scrim Banner Light, Matt M1 (Black Back) 325g/m² | 97004143 | 1100mm x 25m roll

Canon | IJM667 | Scrim Banner Light, Matt M1 (Black Back) 325g/m² | 97001283 | 63" 1600mm x 25m roll

-

Printing Guidelines

Allow material to adapt to room conditions for 24 hours before printing. It is recommended to handle the media with cotton gloves. Make sure that the media comes not into contact with grease, oil, silicon, and dirt to avoid printing defects. Load the media with care in the printers. Incorrect loading can cause skewing or creasing. Use a take- up device to prevent wrinkling.

It is recommended to calibrate the printer before printing and to make a test print. Print results will vary for different printer/ink combinations. Canon media profiles include recommended settings for ink restrictions and printer parameters. Depending on fluctuations in environment, printer, ink, media and applications, printer parameters may have to be adjusted slightly, in order to obtain the best results.

For high-speed production printing, using an external drying unit is recommended. IJM667 has a black coating on the reverse side. Some inkjet printers check the presence of media in the printer, detecting the reverse side of the media by means of an optical sensor. In some cases this optical sensor is not able to detect the reverse side of IJM667 because it is completely black. The printer will not accept this media when loading. The coating of IJM667 is especially developed for digital inkjet printing. However IJM667 also can be screen-printed. It is recommended to do a test on a small area, because every machine and ink can have different properties.

Fibres of the scrim may fray at edges of the banner. Remove frays or use edge guides for preventing fibres touching the printheads. Frays can be removed by fire, using a gaslighter or torch

-

Application Guidelines

Avoid folding a printed banner. Hard creases may not flatten out during installations. When used for banners or other hanging applications, hemming the edges is recommended. Standard high-tack banner tape can be used as well as sewing.

If sewn, it is recommended that the banners are stitched hem side up so that the sewing machine comes into contact only with the reverse surface of the banner. When applying grommets, they should be inserted in double-hemmed edges. Corner grommets should be placed where the length and width hems cross, so that the grommet goes through four layers.

For the manufacture of large surface area posters, individual lengths are overlapped by 2-3 cm and best joined up by means of a high frequency welding system. However, such overlap seam welding can also be carried out by means of a hot air welding unit.

Download a Brochure

-

Canon IJM667 Scrim Banner Light, Matt M1 (Black Back) 325g/mē 97001283 63" 1600mm x 25m roll **LATEX / UV (GEL) / (ECO) SOLVENT** - DATA SHEET

Download