- CAD Plotters

- Wide-Format Photo, Fine Art & Graphic Printers

- HP Latex, Outdoor, Signage, Wall Paper Printers & Cutters

- Wide Format Ink & Media Supplies

- Multi Functional Printers & Plan Copiers

- Large Format Scanners

- Finishing - Large Format Paper Folders, Trimmers, XY Cutters & Laminating

- Canon A4 and A3 Copier Paper

- Canvas, Stretcher Bars & Laminate

- Fabric Printers

- 3D Printers

- Bricsys BricsCAD® Software

- Colour Management & RIP Software

- Plotter Warranties

- Storage & Filing Systems

- OFFERS

Why use plot-IT?

- Est since 1965

- Group turnover - £15 million

- 5 UK offices with over 100 staff

- HP Designjet Warranty Provider

- Autodesk Gold reseller

- Canon Elite Partner

- Stratasys - Gold Partner

Ultimaker Print Core CC+ 0.60mm (237384)

-

Description

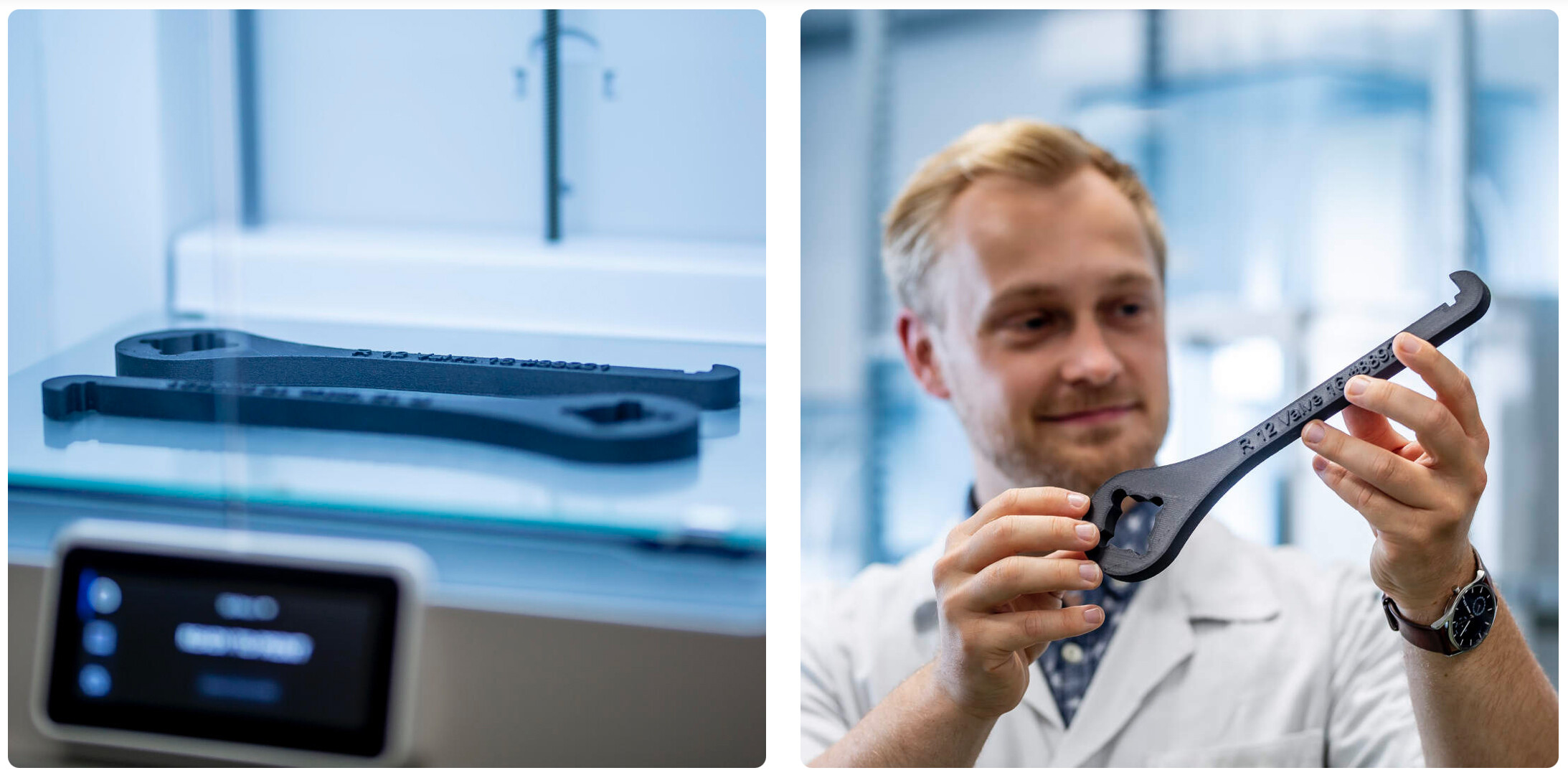

Ultimaker Print Core CC+ 0.60mm (237384): Precision-engineered specifically for printing with abrasive composite materials such as carbon fibre, glass fibre and metal-filled filaments. Built with a hardened steel nozzle and optimised internal geometry, it provides reliable extrusion of high-strength materials while reducing the risk of clogging. The 0.60mm nozzle size offers an ideal balance between strength and detail, making it suitable for both functional prototyping and end-use parts that demand high mechanical performance. The Print Core design allows for simple tool-free swapping, ensuring minimal downtime when changing materials or nozzles.

This CC+ variant is fully compatible with the UltiMaker S5, UltiMaker S7 and UltiMaker S8 3D printers. On the S8, it is one of only two officially supported cores—alongside the AA+ 0.40 mm—for high-speed printing using UltiMaker's quad-core high-flow system. The CC+ 0.60 mm core ensures seamless integration with UltiMaker Cura software, offering preconfigured profiles optimised for composites and supporting features like print core recognition and active levelling. It is also backward-compatible with the S5 and S7, making it a versatile solution for professionals seeking consistent composite performance across UltiMaker’s latest generation of machines.

-

Print Core Compatibility

PRINT CORE TYPE COMPATIBLE MATERIAL TYPES AVAILABLE SIZES COMPATIBLE PRINTERS AA Build materials and Breakaway support 0.25mm

0.4mm

0.8mmUltimaker 3

Ultimaker S3

Ultimaker S5

Ultimaker S6

Ultimaker S7

Factor 4BB Water-soluble (PVA) support material. On the S8, also used for Breakaway support 0.4mm

0.8mmUltimaker 3

Ultimaker S3

Ultimaker S5

Ultimaker S6

Ultimaker S7

Ultimaker S8

Factor 4CC Composite (glass or carbon-filled) materials 0.4mm

0.6mmUltimaker S3

Ultimaker S5

Ultimaker S6

Ultimaker S7

Factor 4DD* Ultrafuse Support Layer material (Metal Expansion kit) 0.4mm Ultimaker S3

Ultimaker S5

Ultimaker S6

Ultimaker S7

Factor 4HT High-temperature materials such as UltiMaker PPS CF 0.6mm Factor 4 AA+ High-flow, high-speed printing with (non-composite) build materials 0.4mm Ultimaker S5

Ultimaker S6

Ultimaker S7

Ultimaker S8CC+ High-flow, high-speed printing with composite materials 0.4mm(Obsolete)

0.6mmUltimaker S5

Ultimaker S6

Ultimaker S7

Ultimaker S8*The DD print core and Ultrafuse Support Layer material are only available in selected regions.

COMPATIBILITY EXPLANATION: The AA and BB print cores are compatible with all UltiMaker printers that use print cores (UltiMaker 3, S series, and Factor 4). These print cores are not intended for use with abrasive materials. The CC print cores are only compatible with UltiMaker printers with abrasion-resistant feeders (S series and Factor 4). These print cores are intended for use with abrasive or composite materials. These print cores cannot be used on the UltiMaker 3, because the UltiMaker 3 feeders are not compatible with composite materials. See more information about the AA and CC cores on the UltiMaker S8 below. The CC print cores can also be used in combination with the Material Station. The Material Station has abrasion-resistant prefeeders in all material bays. However, the Material Station is not compatible with all composite materials. Please check the latest profiles in the UltiMaker Marketplace to determine if the material can be used with the Material Station. The DD cores are not recommended for use with the S series Material Station. The DD print cores currently only support Ultrafuse Support Layer filament, which is used when printing metal. This is not recommended with the S series Material Station due to the curves in the internal filament path. On Factor 4, the filament path is different (smoother) so this does not affect the Ultrafuse material as much. The HT print cores are only compatible with Factor 4. This print core type is optimized for high-temperature materials, such as UltiMaker PPS CF. This material requires a high printing and build volume temperature to print reliably; only Factor 4 features a heated build chamber. The AA+ and CC+ print cores feature redesigned nozzles optimised for faster material melting and deposition, ensuring seamless compatibility with UltiMaker Cheetah motion planning. This advanced motion planner is exclusive to the UltiMaker S8. Regular AA and CC print cores can be used on the S8, but this workflow is not fully supported. These cores are not designed for the high-speed capabilities of the S8. The AA and CC cannot be selected for S8 in Cura; no profiles are developed for this configuration. To use the regular AA and CC cores on the S8, you can slice the print job for UltiMaker S7 instead and print it on S8.