- CAD Plotters

- Wide-Format Photo, Fine Art & Graphic Printers

- HP Latex, Outdoor, Signage, Wall Paper Printers & Cutters

- Wide Format Ink & Media Supplies

- Multi Functional Printers & Plan Copiers

- Large Format Scanners

- Finishing - Large Format Paper Folders, Trimmers, XY Cutters & Laminating

- Canon A4 and A3 Copier Paper

- Canvas, Stretcher Bars & Laminate

- Fabric Printers

- 3D Printers

- Bricsys BricsCAD® Software

- Colour Management & RIP Software

- Plotter Warranties

- Storage & Filing Systems

- OFFERS

Why use plot-IT?

- Est since 1965

- Group turnover - £15 million

- 5 UK offices with over 100 staff

- HP Designjet Warranty Provider

- Autodesk Gold reseller

- Canon Elite Partner

- Stratasys - Gold Partner

Summa V-Cut Tool - 45 deg (up to 18mm Thick) for F Series Flatbed Cutters (500-9344)

- Description

- F-series Modules & Tools

- Tech specs

- Suitable Materials

- Other related products

- Compatibility

-

Description

Summa V-Cut Tool - 45 deg (up to 18mm Thick) for F Series Flatbed Cutters (500-9344):

Designed to deliver precise bevelled cuts at a 45° angle in materials up to 18mm thick. This tool is ideal for creating sharp bevelled edges and deep cuts in a range of materials, providing excellent structural integrity for applications such as signage, packaging and custom displays. The 45° angle ensures smooth and professional results, allowing businesses to create seamless joints and folded structures with ease.

Optimised for Summa F Series Flatbed Cutters, the V-Cut Tool - 45° performs exceptionally well on a variety of materials including foam board, corrugated plastic, honeycomb panels and rigid display boards. These materials are frequently used in the signage, packaging and display industries where strong bevelled edges are needed for efficient assembly and durability. The V-Cut Tool - 45° ensures clean cuts with minimal effort, reducing material waste and increasing overall productivity in professional production environments.

The Summa V-Cut Tool - 45° features a high-quality, durable blade that ensures consistently sharp cuts and long-lasting performance. Its robust construction makes it ideal for high-volume production, providing reliable and accurate cutting every time. By integrating seamlessly with Summa’s advanced cutting systems, the tool enhances overall cutting accuracy and efficiency, helping businesses meet tight production deadlines without compromising on quality.

Designed for quick and easy tool changes, the Summa V-Cut Tool - 45° allows operators to efficiently switch between different cutting tasks, maximising productivity. Whether used for creating intricate display elements, custom packaging designs or durable structural pieces, this tool ensures precision and flexibility, making it a valuable asset for businesses in need of versatile cutting solutions.

KEY FEATURES:

- PRECISE 30° CUTTING ANGLE: Ideal for creating deep bevelled cuts that ensure strong structural joints and enhanced interlocking designs.

- SUPPORTS MATERIALS UP TO 23MM THICK: Suitable for foam board, corrugated plastic, honeycomb panels and rigid display boards.

- SEAMLESS F SERIES INTEGRATION: Fully compatible with Summa F Series Flatbed Cutters, delivering high cutting precision and efficient workflow.

- DURABLE BLADE MECHANISM: Offers consistent sharp cuts with reduced material waste and less maintenance required.

- FAST & EASY TOOL CHANGES: Quick-swap design allows for seamless transitions between different cutting tasks, optimising production efficiency.

- IDEAL FOR STRUCTURAL DISPLAY & PACKAGING: Perfect for creating high-quality structural displays, signage and packaging with deep bevelled edges.

-

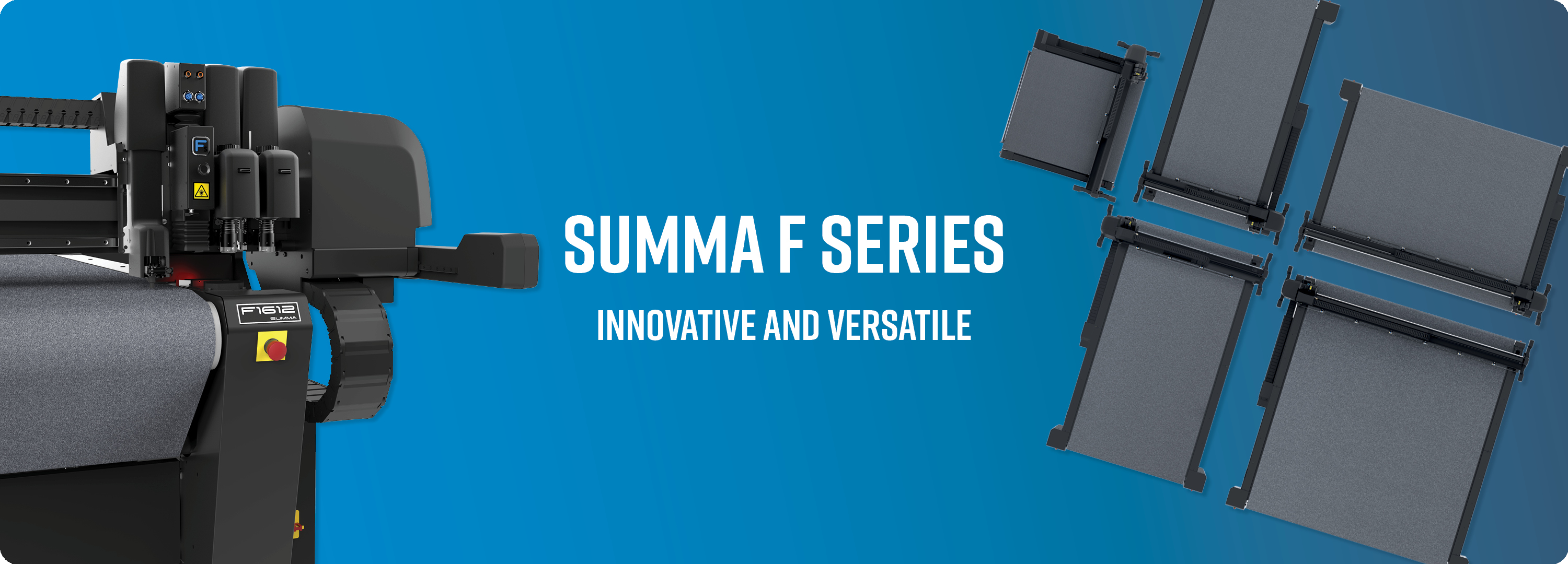

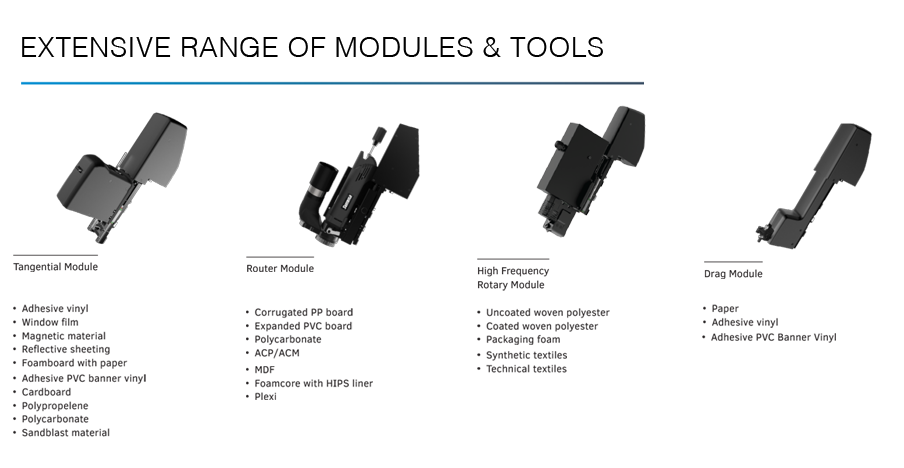

F-series Modules & Tools

The F Series models feature a multi-functional cutting head capable of holding up to three cutting modules simultaneously. This allows the system to efficiently handle cutting jobs that require multiple techniques or to switch quickly between tasks involving different materials. The integrated camera system and LED pointer in the central unit ensure precise and rapid mark recognition for flawless operation.

Each module can accommodate a variety of tools, blades and bits, allowing you to select the ideal tool for cutting your specific material and achieving the highest quality results. Every tool features a barcode ID for automatic recognition and parameter pre-sets. As your business expands, you can easily extend your tool range to meet new production demands.

AUTOMATIC DEPTH CONTROL:

The Automated Depth Control (ADC) simplifies tool, knife or bit changes significantly. The ADC measures the tip of the knife or bit accurately and sets the down position of the tool to the table’s level, thus guaranteeing a flawless cut.

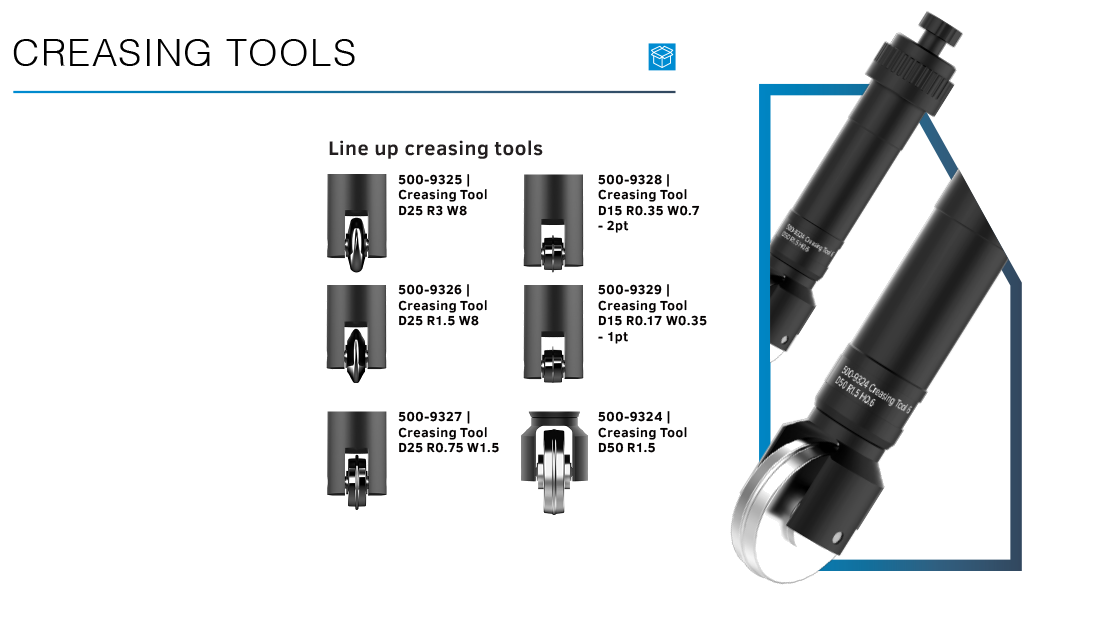

Several creasing wheels, designed in different depths and radius sizes, are available for creasing and scoring paper, cartons, polypropylene and PVC material.

Several creasing wheels, designed in different depths and radius sizes, are available for creasing and scoring paper, cartons, polypropylene and PVC material.FEATURES:

- Clean creases without tearing

- Directional pressure adjustments

IDEAL FOR CREASING:

- Corrugated B-C-A-EE-BC flute (3 - 6mm)

- Corrugated C Flute (4mm)

- Corrugated E Flute (1.5mm)

- Paper < 200gr • Cardboard 300 - 500g/m²

- Polypropelene sheets <= 1.2mm

- Corrugated B-C-A-EE- BC flute (3-6mm)

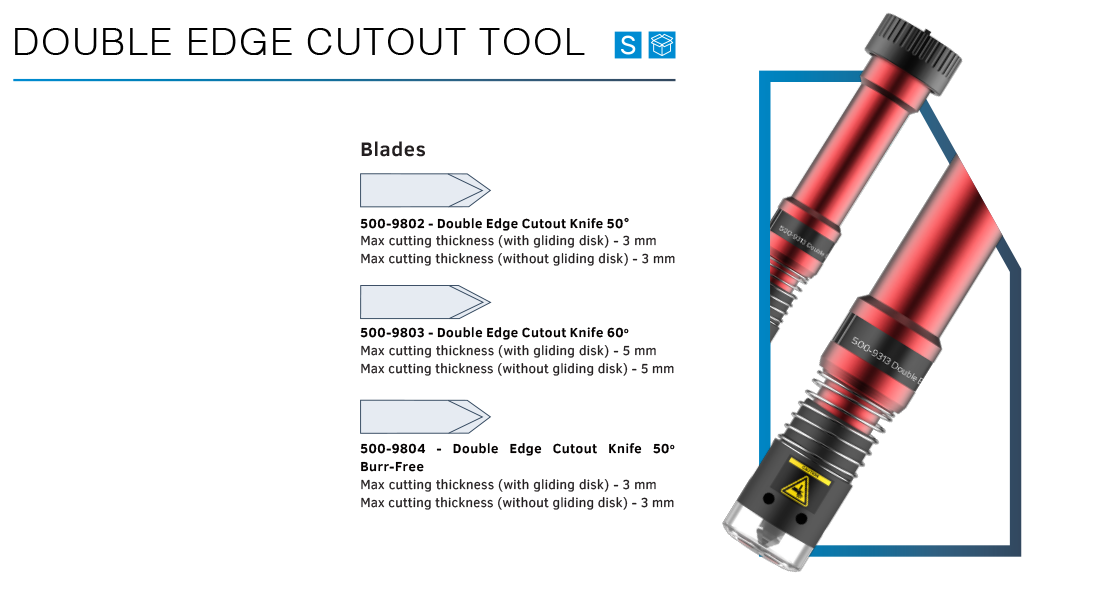

The Double Edge Cutout Tool ensures minimal wear when cutting through rigid material up to 5mm thick. Here also, a spring-loaded gliding disk allows cutting of very precise details and can be fixed at a set depth.

FEATURES:

- Precise cutting of details

- Cuts at both knife sides

- Minimal knife wear

- Ideal to cut rigid material

IDEAL FOR CUTTING:

- Paper < 200g/m²

- Cardboard 300-500g/m²

- Adhesive vinyl

- Adhesive PVC

- PVC Banner

- Reflectivesheeting

- Expanded PVC board <= 1.2mm

- Polypropelene <= 1.2mm

- Polycarbonate <= 0.6mm

- Magnetic material

Ideal for cutting soft and medium density materials such as corrugated board and foam up to 18mm thick. The Electronic Oscillating Tool is driven by an electric motor, producing up to 12,000 rpm and moves a knife up and down over a stroke of 1mm.

Ideal for cutting soft and medium density materials such as corrugated board and foam up to 18mm thick. The Electronic Oscillating Tool is driven by an electric motor, producing up to 12,000 rpm and moves a knife up and down over a stroke of 1mm.FEATURES:

- Powerful cutting tool

- High processing speeds

- Low maintenance

IDEAL FOR CUTTING:

- Corrugated B-C-E Flute (1.5-4 mm)

- Foamcore with paper liner <= 10mm

- Foamcore with pa- per liner > 5mm

- Honeycomb board < 10mm

- Gasket

The Heavy-Duty Cutout Tool is suitable for cutting through thicker materials up to 15mm thick.

The Heavy-Duty Cutout Tool is suitable for cutting through thicker materials up to 15mm thick.FEATURES:

- Ideal to cut very thick material

IDEAL FOR CUTTING:

- Cardboard 300-500g/m²

- Adhesive vinyl

- Adhesive PVC

- PVC Banner

- Corrugated PP board <= 5mm

- Expanded PVC board <= 1.2mm

- Polypropelene <= 1.0mm

- Polycarbonate <= 0.6mm

- Foamcore with paper liner <= 5mm

- Varnish blankets

With mechanically-controlled knife pressure, this tool is specifically designed for kiss-cutting material down to its liner up to 1.2mm thick. This tool also includes an adjustable nose piece for precise depth control.

FEATURES:

- Precise depth control

- Clean cuts for easy weeding

- Cuts a wide variety of vinyl and film

IDEAL FOR CUTTING:

- Paper < 200g/m²

- Adhesive vinyl

- Sandblast material

- Window film

- Magnetic material

- Adhesive PVC Banner material

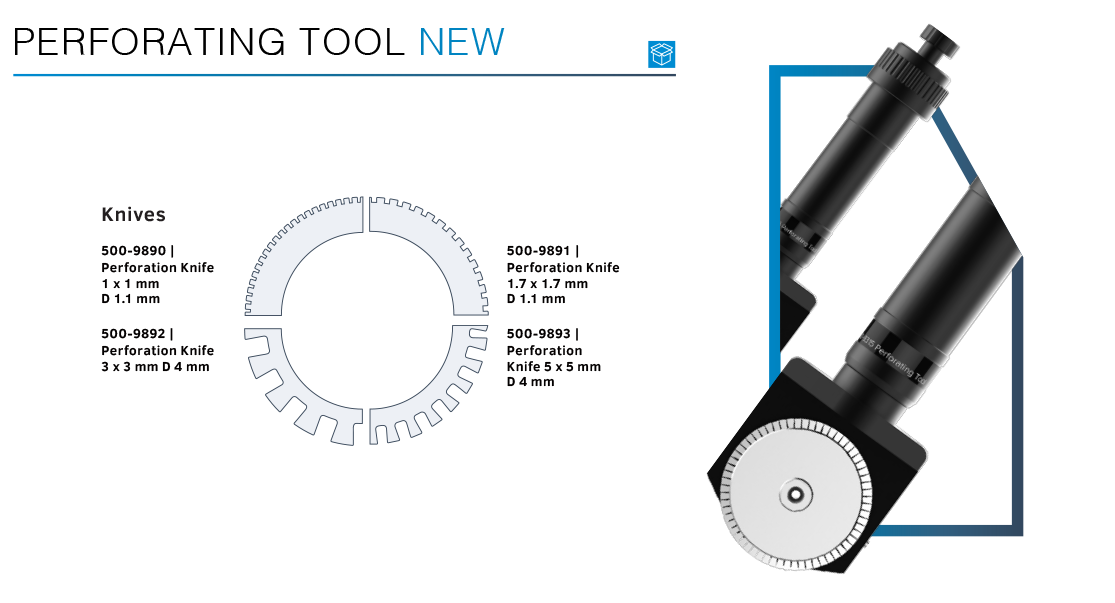

The new Summa perforating tool for the F Series is used to make perforations in a very efficient and fast way. By using this tool, the perforated materials will be a lot easier to bend or fold. Then, the folds will have sharper 90° edges resulting in a nicer finish. This will save considerable time in the assembling of, for instance, cardboard or polypropylene boxes.

The new Summa perforating tool for the F Series is used to make perforations in a very efficient and fast way. By using this tool, the perforated materials will be a lot easier to bend or fold. Then, the folds will have sharper 90° edges resulting in a nicer finish. This will save considerable time in the assembling of, for instance, cardboard or polypropylene boxes.FEATURES:

- Up to 25 times faster cutting of perforation lines (versus EOT tool)

- Alternative for creasing. Folding and bending lines into cardboard

- High-quality perforated cuts

- Several knives available

IDEAL FOR CUTTING:

- Solid cardboard

- Corrugated board

- Polypropylene film

The standard Pneumatic Oscillating Tool, powered by compressed air, moves its knife up and down over a stroke of 8mm. The robust construction of the tool makes it suitable to cut thick material, such as honeycomb board, corrugated board and foam board.

The standard Pneumatic Oscillating Tool, powered by compressed air, moves its knife up and down over a stroke of 8mm. The robust construction of the tool makes it suitable to cut thick material, such as honeycomb board, corrugated board and foam board.FEATURES:

- High-performance cutting tool

- High processing speeds

- Availability of longer knife

IDEAL FOR CUTTING:

- Triple walled cardboard

- Double walled cardboard

- Packaging Foam

- Honeycomb board >= 10mm

- Foamcore with paper liner> 5mm

- Re-board®

- Foamboard with plastic

- Rubber

The Pneumatic Oscillating Tool-L (POT-L) is an addition to the standard POT and is used with a Longer type of knife. The POT-L is able to process thick, soft foams with a maximum thickness up to 42mm. The robust construction of the tool makes it suitable to cut thick material, such as honeycomb board, corrugated board and foam board.

The Pneumatic Oscillating Tool-L (POT-L) is an addition to the standard POT and is used with a Longer type of knife. The POT-L is able to process thick, soft foams with a maximum thickness up to 42mm. The robust construction of the tool makes it suitable to cut thick material, such as honeycomb board, corrugated board and foam board.FEATURES:

- High-performance cutting tool

- High processing speeds

- Availability of longer knife

IDEAL FOR CUTTING:

- Triple walled cardboard

- Double walled cardboard

- Packaging Foam

- Honeycomb board >= 10mm

- Foamcore with paper liner> 5mm

- Re-board®

- Foamboard with plastic

- Rubber

The Single Edge Cutout Tool is designed for detailed cutting through materials up to 6mm thick. A spring-loaded gliding disk allows cutting of very precise details and can be fixed at a set depth.

FEATURES:

- Precise cutting of details

- Cuts material up to 6mm thick

- Fixed depth setting

IDEAL FOR CUTTING:

- Paper < 200g/m²

- Cardboard 300-500g/m²

- Adhesive vinyl

- Foamboard <= 2mm

- Polypropelene <= 1.2mm

- Polycarbonate <= 0.6mm

- Adhesive PVC

- Magnetic material

The V-Cut Tools are available in 5 angles and are designed to cut a V-shaped groove in rigid sandwich and foam composite boards up to 27mm thick, depending on the material’s density.

The V-Cut Tools are available in 5 angles and are designed to cut a V-shaped groove in rigid sandwich and foam composite boards up to 27mm thick, depending on the material’s density.FEATURES:

- Precise angle adjustment

- Very fast blade changes

IDEAL FOR CUTTING:

- Honeycomb board

- Foamcore with paper liner

-

Tech specs

- CUTTING ANGLE: 45° (bevel cut)

- MAXIMUM MATERIAL THICKNESS: Up to 18mm

- TOOL CHANGING: Quick and easy swap mechanism

-

Suitable Materials

- Foam board

- Corrugated plastic

- Honeycomb panels

- Rigid display boards

-

Other related products

-

Summa V-Cut Tool - 0° (Up to 27mm Thick) (500-9340)

Designed for vertical cuts in thick materials up to 27mm. Ideal for creating rigid displays, signage and packaging prototypes with clean, straight edges. -

Summa V-Cut Tool - 15° (Up to 26mm Thick) (500-9341)

Provides precise bevelled cuts at a 15° angle, allowing for interlocking and foldable designs in packaging, display and structural applications. -

Summa V-Cut Tool - 22.5° (Up to 22mm Thick) (500-9342)

Optimised for angled cuts at 22.5°, this tool is suitable for creating complex structures and 3D elements in foam board, honeycomb panels and rigid display materials. -

Summa V-Cut Tool - 30° (Up to 18mm Thick) (500-9343)

Designed for deeper bevelled cuts at a 30° angle, allowing for precise folding applications in packaging, display and model construction projects. -

Summa V-Cut Tool - 45° (Up to 16mm Thick) (500-9344)

Provides a sharp 45° angle cut, perfect for deep bevelled edges and creating seamless joints in thick materials used for signage and three-dimensional structures.

-

-

Compatibility

- Summa F1612 Flatbed Cutter

- Summa F1432 Flatbed Cutter

- Summa F1832 Flatbed Cutter

- Summa F3220 Flatbed Cutter

- Summa F3232 Flatbed Cutter

- Summa F3330 Flatbed Cutter

Download a Brochure

-

Summa V-Cut Tool - 45 deg (up to 18mm Thick) for F Series Flatbed Cutters (500-9344) - SUMMA F SERIES BROCHURE

Download