- CAD Plotters

- Wide-Format Photo, Fine Art & Graphic Printers

- HP Latex, Outdoor, Signage, Wall Paper Printers & Cutters

- Wide Format Ink & Media Supplies

- Multi Functional Printers & Plan Copiers

- Large Format Scanners

- Finishing - Large Format Paper Folders, Trimmers, XY Cutters & Laminating

- Canon A4 and A3 Copier Paper

- Canvas, Stretcher Bars & Laminate

- Fabric Printers

- 3D Printers

- Bricsys BricsCAD® Software

- Colour Management & RIP Software

- Plotter Warranties

- Storage & Filing Systems

- OFFERS

Why use plot-IT?

- Est since 1965

- Group turnover - £15 million

- 5 UK offices with over 100 staff

- HP Designjet Warranty Provider

- Autodesk Gold reseller

- Canon Elite Partner

- Stratasys - Gold Partner

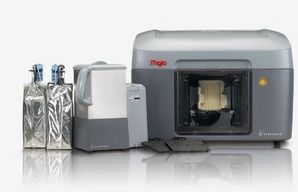

Mojo 3D Printer by Stratays

Stratasys Mojo 3D Printer

Click the yellow arrows to view multiple buying options...

-

Please contact us on 01905 454 598 for a quote

-

Description

Stratasys Mojo 3D Printer allows you to print professional 3D models right at your desk. It is easy to setup and is simplistic to operate – as easy as changing the ink in an inkjet printer. The Mojo 3D Printer is powered by Stratasys " Fused Deposition Modeling " (FDM) Technology, building accurate functional concept models, rapid prototypes & product mockups in ivory ABSplus thermoplastic.

QuickPack Print Engines contain the model & support materials that build your 3D printed parts. With every material change, the Mojo Print Engine installs a fresh print head to ensure optimum print quality which is also easy to use & fast to change. Each foil bag contains 80 cubic inches of material, which means fewer material changes & more uninterrupted printing.

The stratasys wash station the WaveWash 55 lets you quickly remove support material hands-free. The Mojo 3D Printer uses Soluble Support Technology (SST) so that the support material dissolves away in a water-based solution. You just pop your completed concept model off the modeling base & place it in the WaveWash 55. The WaveWash 55 maintains the right solution temperature & agitation for efficient support removal. No plumbing is required & the coffee pot like design simply allows you to pour away the solution through a standard domestic drain / sink - the solution can be used mulitple times prior to disposal.

-

Specifications

Model material:

P430 ABSplus in ivory

Support material:

SR-30 Soluble

Build size:

12.7 x 12.7 x 12.7 cm (5 x 5 x 5 in)

Layer thickness:

.178 mm (.007 in)

Workstation compatibility:

Windows XP/ Windows 7

Size and weight:

Mojo 3D Printer:

63 x 45 x 53 cm (25 x 18 x 21 in)

27 kgWaveWash 55 Support Cleaning System:

33.5 x 33.5 x 33.5 (13.2 x 13.2 x 13.2 in)

5 kgMaximum Size Part(s): 127 x 127 x 127 mm / (5 x 5 x 5 in)

Volume Capacity: 3.78 L (1 gallon)Power requirements:

Mojo 3D Printer: 220-240 VAC, 2.5A, 50 Hz

WaveWash 55 Support Cleaning System: 220-240 VAC, 4A, 50 Hz

Regulatory compliance:

Mojo 3D Printer:

CE / TUV / KCC / RoHS / WEEEWaveWash 55 Support Cleaning System:

CE / TUV / RoHS / WEEE -

How Does Mojo work?

From the CAD drawing on your screen to the 3D concept model in your hand, the Mojo 3D Printer will improve your workflow, fitting seamlessly into your workday.

How to print with Mojo

Printing with Mojo in just three easy steps:

Prepare your CAD file. If you can design in CAD software, you can print your design with Mojo. The remarkably easy-to-use Print Wizard software that comes with your Mojo 3D Printer converts the STL output from your CAD software into precise deposition paths that guide the extrusion head, printing your model one layer at a time. The Print Wizard automatically slices and orients your concept model and creates any necessary support structures, too. All you have to do is click "print."

Print your concept model. The Mojo 3D Printer uses patented Stratasys FDM (Fused Deposition Modeling) technology to print your 3D concept model and its support material, layer by layer, into an ABSplus model. Mojo 3D Printers precisely deposit layers as fine as 0.007" thick – as thin as a postcard.

Remove the support. Remove your concept model from the Mojo build chamber, pop it off the modeling base and remove the soluble support material using the WaveWash 55 Support Cleaning System. It's a hands-free way to remove support material, and its eco-friendly, too. After the support material is removed, you can put the durable ABSplus plastic model through just about any post-processing you need: drilling, painting or even plating.

ABSplus for accuracy and durability

The ABSplus material used by the Mojo 3D Printer gives your ideas the shape and durability they need, whether your concept models are being passed around a conference table or subjected to functional testing. A true industrial thermoplastic, ABS is widely used in thousands of applications. ABSplus is tough enough to withstand even rigorous functional and field testing, including high-performance automotive, military and medical requirements.

FDM makes it all happen

The Mojo 3D Printer is FDM Technology at its best. In fact, Mojo is the tenth generation of Stratasys 3D Printers, which means it's backed by years of innovation and field experience.

FDM is a two-material process. As part of the QuickPack Print Engines, filaments of ABSplus thermoplastic modeling material and soluble support material are fed into print heads. The Mojo print heads glide quickly and quietly in X-Y coordinates above the build chamber and the modeling base moves down the Z-axis to build your 3D model and its support material, layer by layer. After your model is built, the soluble supports can be simply dissolved away.

-

Our Opinion

Great Value 3D printer that provides small functional parts & is placeable in any office. A small engineering change, which could cost £100 or less in the concept phase, could balloon to thousands of pounds if the same design change needs to be made once the product is in the field. Mojo 3D Printers help you to reduce those costs with better collaboration and design verification throughout the process. Mojo is able to produce quick, inexpensive functional prototypes made of ABSplus plastic, allowing you to see any possible design flaws right away. With the Mojo 3D printer right at your desk, making that small iteration to improve your functional prototype can now be completed in mere hours. Your Mojo 3D Printer could pay for itself on its first project.

Unlie other entry level devices Mojo uses stratasys ABS print material providing you with strong useable models.