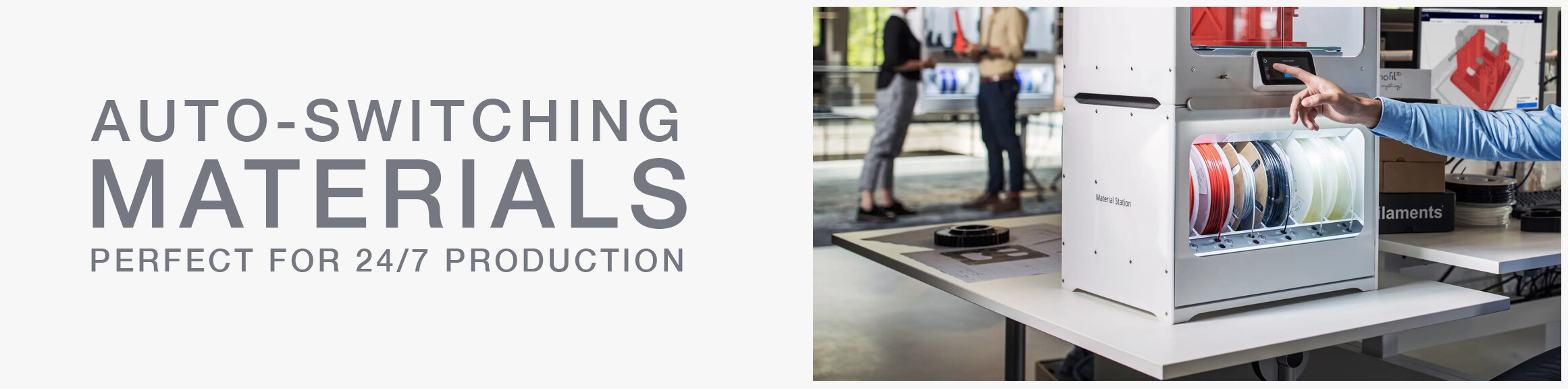

Seamlessly integarating with the Ultimaker S5/S6/S7 and S8, the Material Station redefines material handling – to unlock truly 24/7 production. Load up to six material spools inside the humidity- controlled chamber and smart features take care of the rest: Composite-ready feeder wheels, filament flow sensors, and automatic switching when a material runs out. Now you can achieve increased productivity and higher-quality production.

The Ultimaker S5/S6/S7/S8 Material Station marks an important contribution to a ‘no-hassle’ office solution. As part of the Ultimaker S5 Pro Bundle, it features easy front loading for up to six spools of filament, end-of-filament detection, NFC recognition with compatible materials, and automatic material switching.

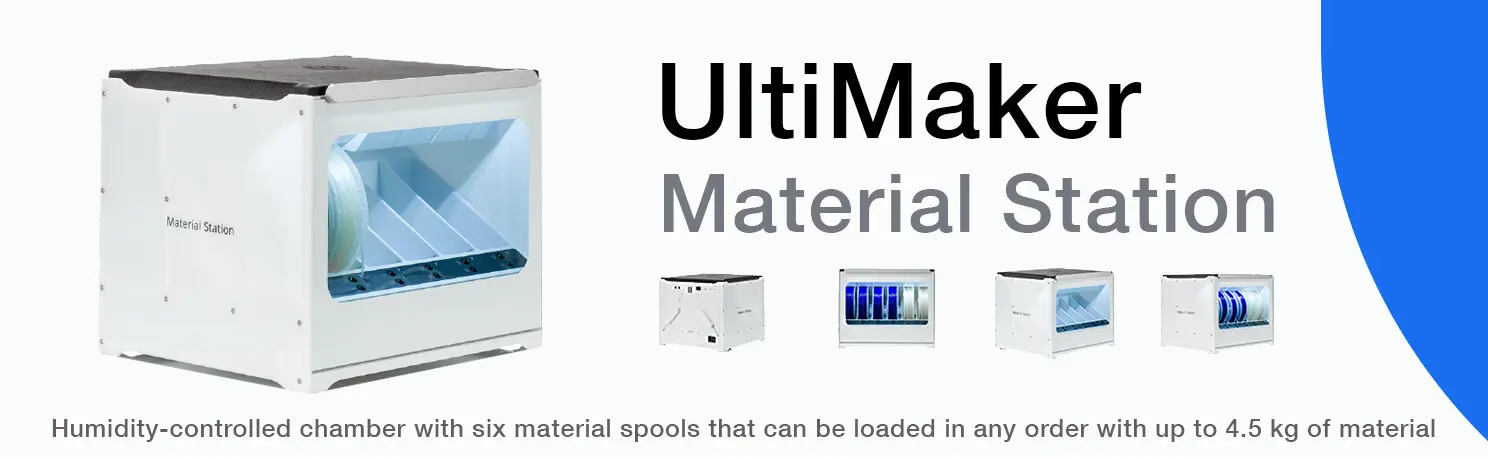

The Ultimaker S5/S7/S8 Material Station Material Station stands as an advanced humidity-controlled chamber designed to accommodate six material spools, allowing flexible loading of up to 4.5kg of material in any order. Boasting cutting-edge features, each bay within the station incorporates automatic material switching, composite-ready feeder wheels, and filament flow sensors.

KEY FEATURES:

- FAST & EASY LOADING: Front-facing bay for up to six materials reduces loading time to a few seconds

- UNINTERRUPTED PRINTING: Sensors detect when one material spool ends and automatically loads the next

- HUMIDITY CONTROL: Intelligent atmospheric management keeps relative humidity below 40%

- EASY SET-UP & MONITORING: NFC material auto- recognition and seamless integration with Ultimaker software

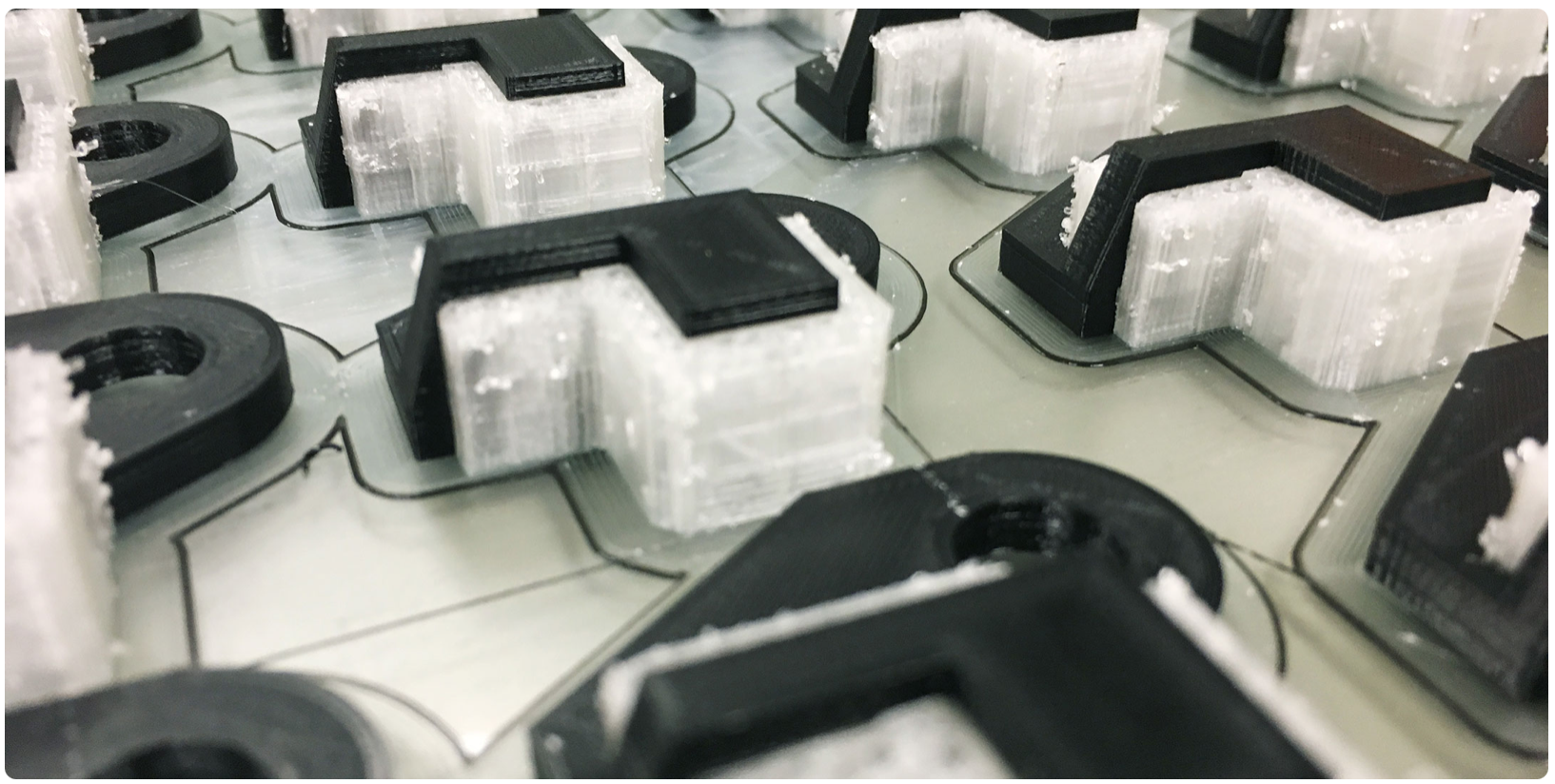

- COMPOSITE MATERIALS COMPATIBLE: Print parts with high strength and unique properties

- LIMITLESS CONFIGURATIONS: Keep your most-used materials ready to print when you need – Ultimaker and third-party filaments