UltiMaker METHOD X ABS-R Filament Black (375-0071A):

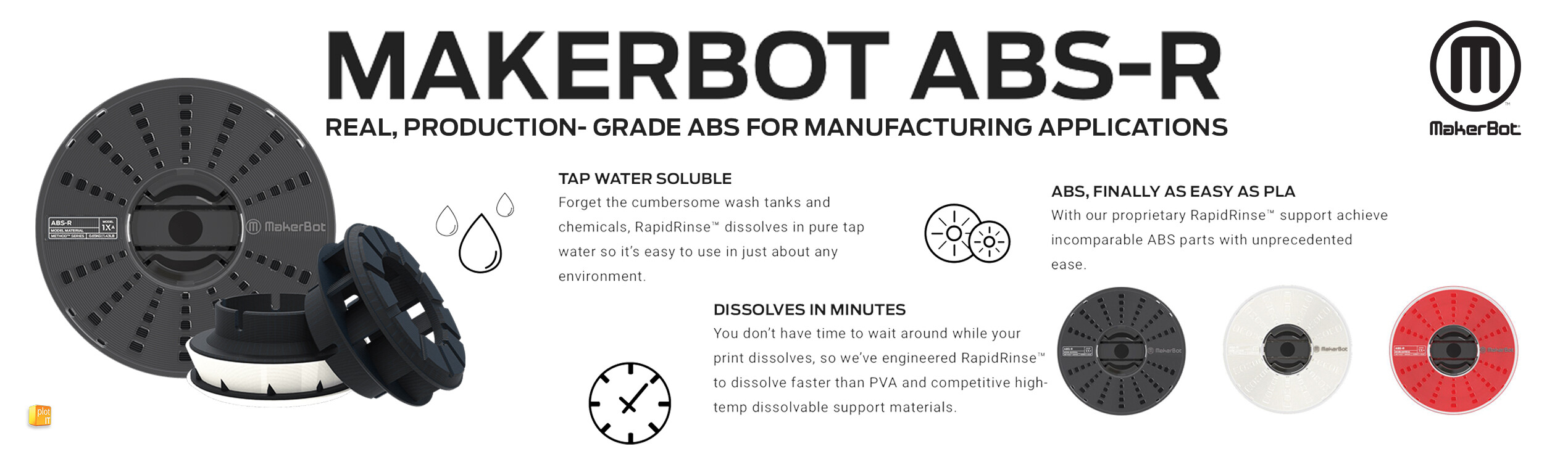

ABS-R is a new ABS formulation that provides superior printing reliability and performance with a 98% jam reduction for consistent, repeatable ABS prototypes, tools, and parts. Works with RapidRinse™ Fast Dissolving Support.

ABS is one of the most popular materials for injection molded consumer products due to its clean surface finish, durability, and heat resistance. METHOD X can print manufacturing-grade ABS without warping and without weakening additives thanks to its 100°C heated chamber.

AVAILABLE COLOURS:

APPLICATIONS:

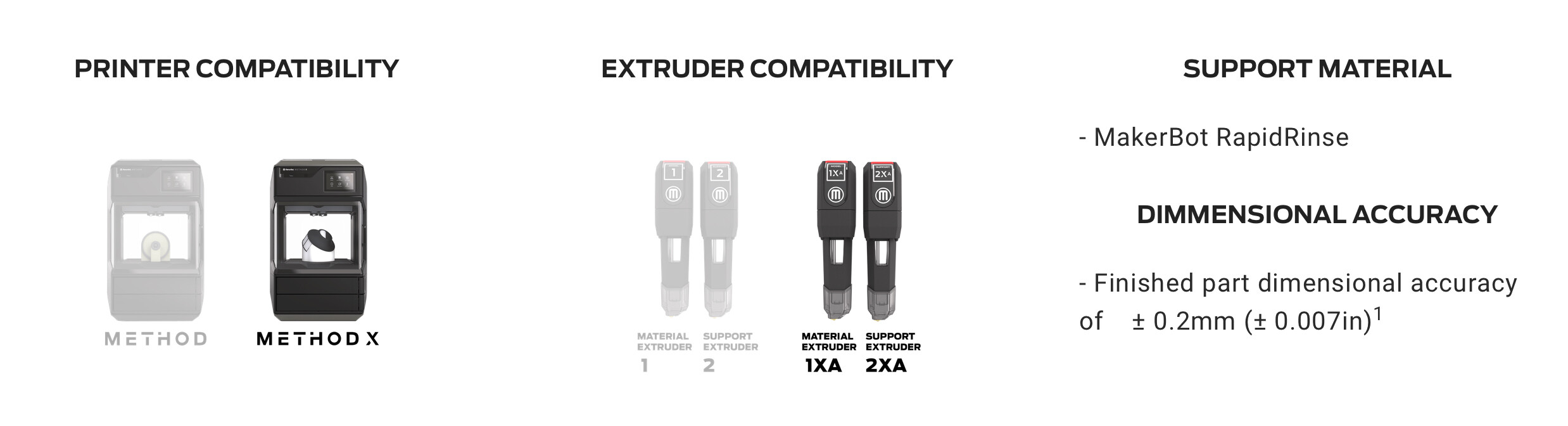

END OF USE PARTS: Get dimensionally-accurate, production-grade, real ABS end-use parts at a fraction of traditional manufacturing costs. METHOD reduces costs and saves time for small production manufacturing runs.

MANUFACTURING TOOLS: Prototype with production-grade ABS to achieve part properties close to injection molded parts. Print dimensionally accurate assemblies and validate your designs to get your products to market faster—all at a fraction of industrial 3D printing costs.

FUNCTIONAL PROTOTYPES: Create durable, real ABS parts for the production floor. Print dimensionally accurate jigs, fixtures, and end-effectors that fit seamlessly with existing components.