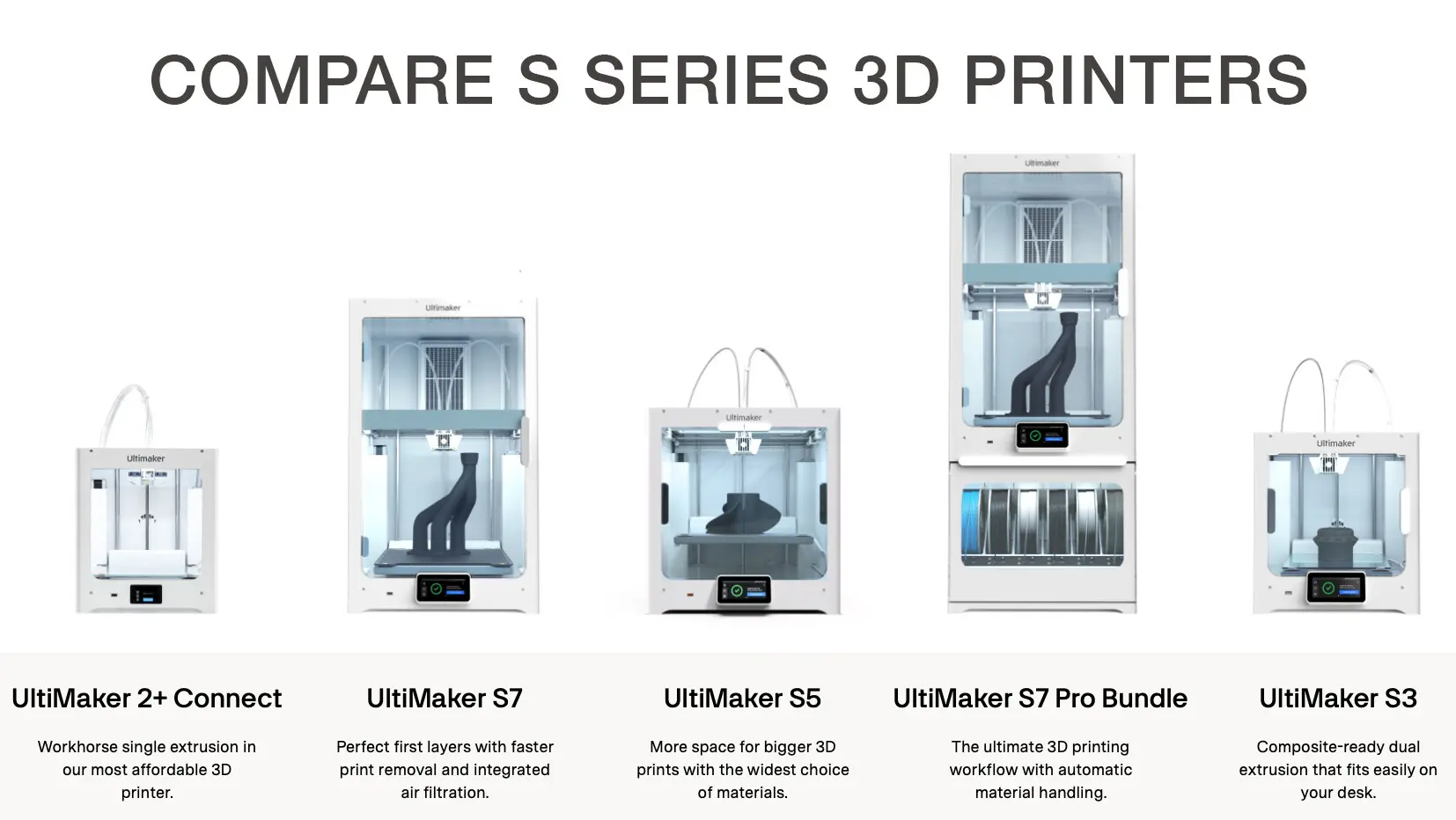

UltiMaker S3 3D Printer (216934)

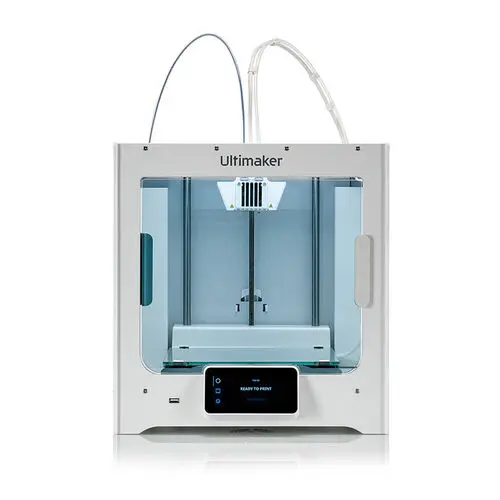

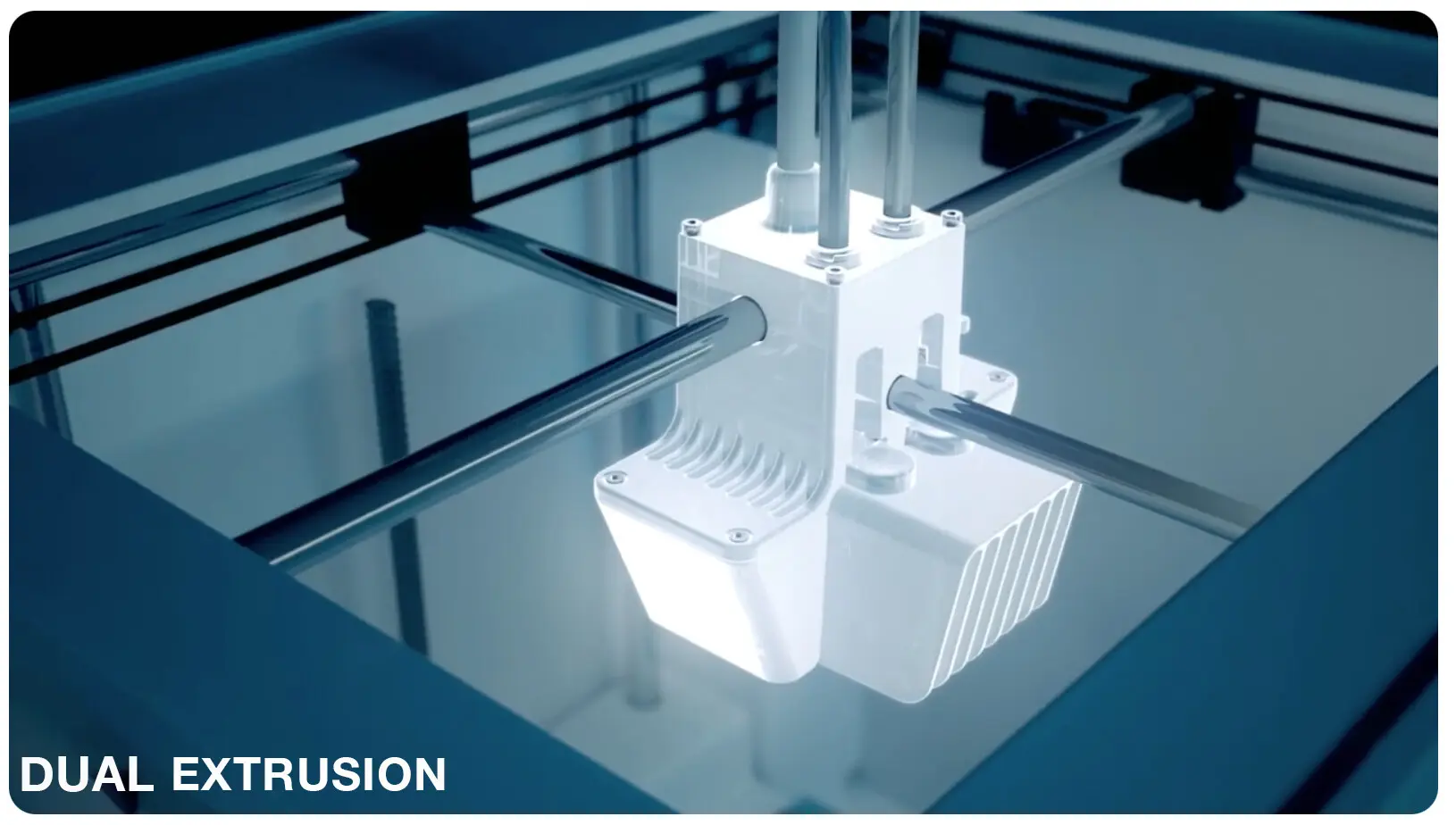

Designed for versatility in any workspace, the Ultimaker S3 boasts advanced dual extrusion capabilities, perfect for handling a variety of materials with ease. Ultimaker have integrated cutting-edge technology to ensure a seamless and user-friendly experience, combining power and simplicity in one impressive package.

With its low annual cost of ownership, the Ultimaker S3 offers an affordable entry to professional 3D printing, making ROI easy and fast to achieve. This means that entrepreneurs and SMEs can now get more for their initial outlay and those who want to drive innovation using additive manufacturing now have a lower barrier to entry without needing to compromise on performance.

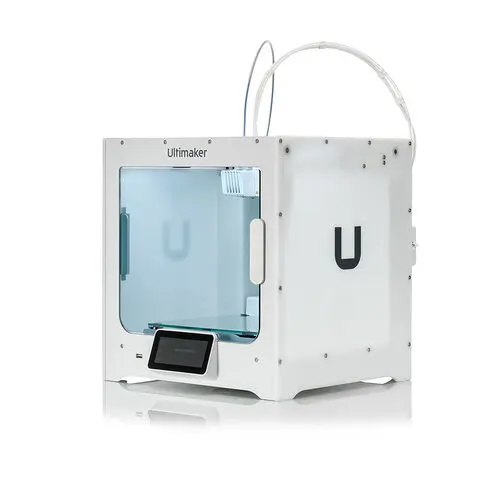

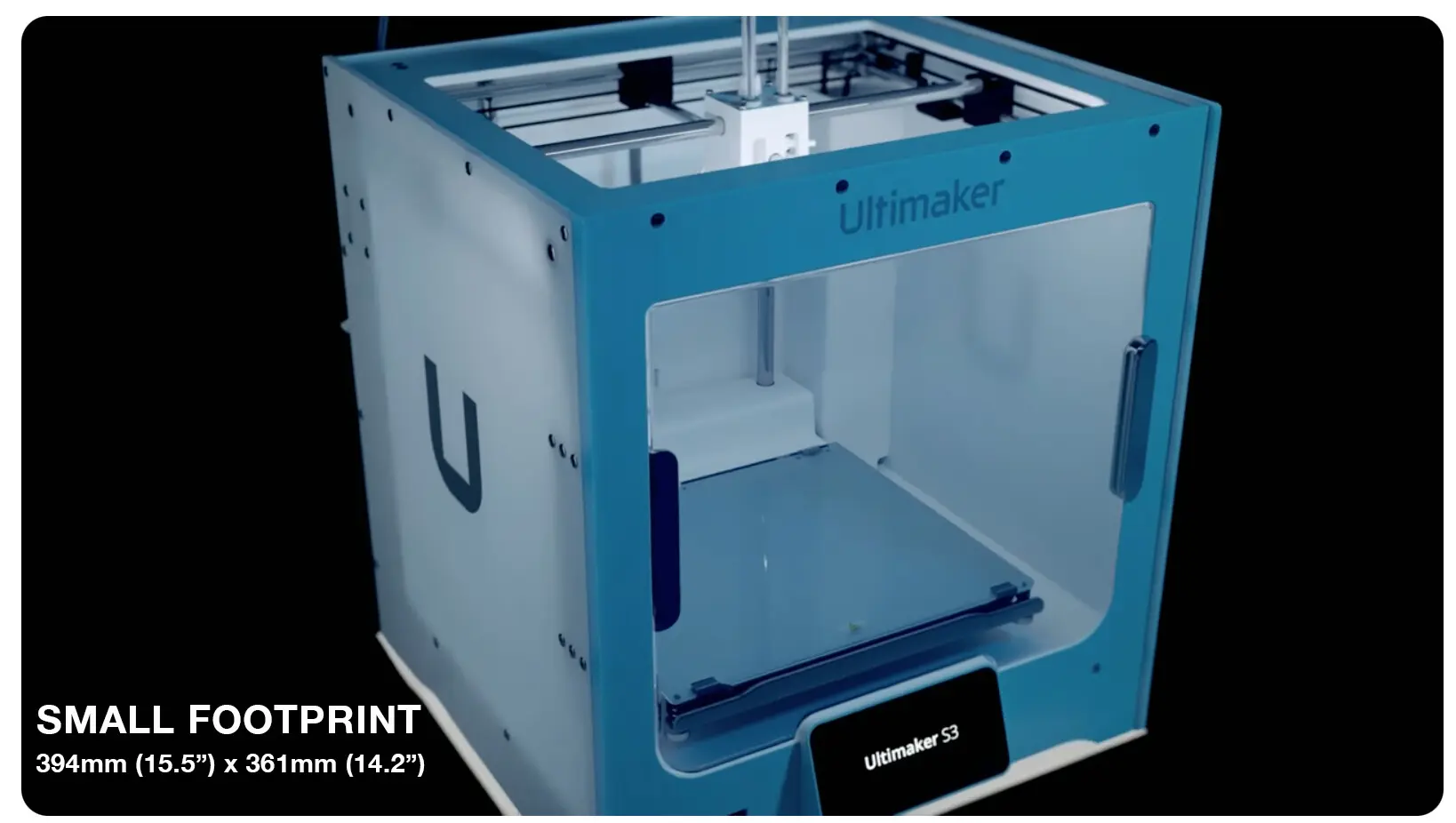

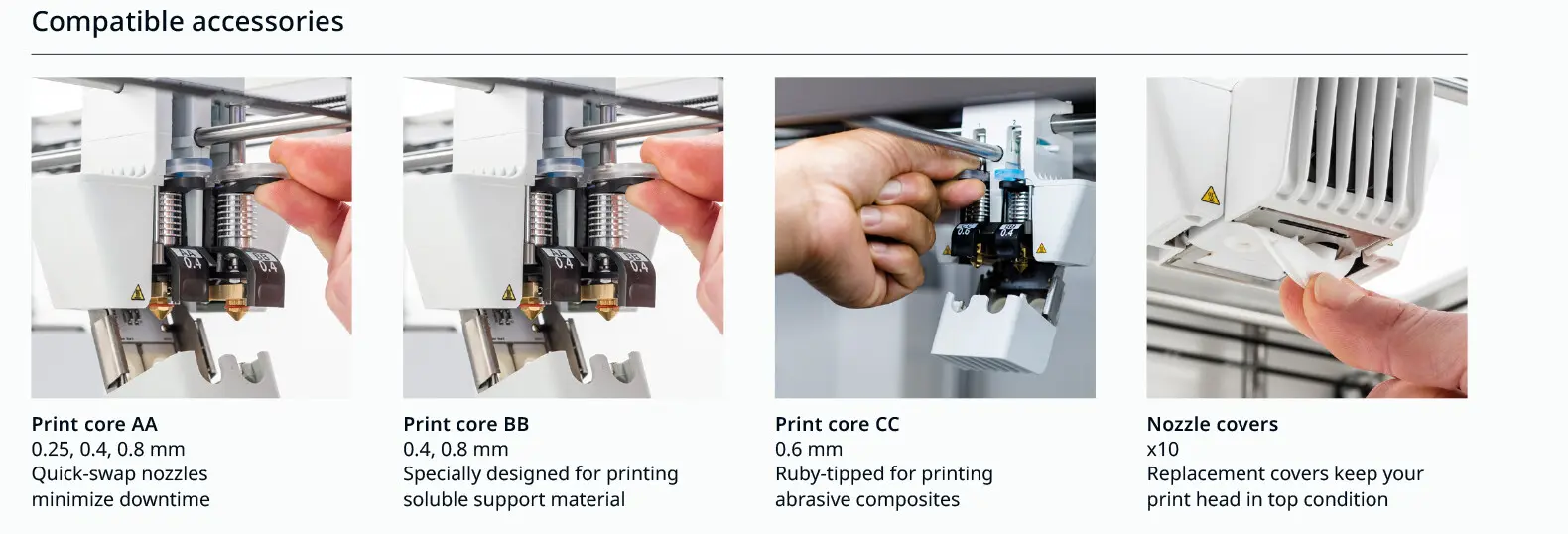

Whether you’re a seasoned professional or a newcomer to 3D printing, the Ultimaker S3 offers an unmatched balance of performance and accessibility. Ultimaker have taken many of the best features from the Ultimaker S5 and combined them into a smaller, more affordable device. The Ultimaker S3 delivers the same high-quality, composite-ready dual extrusion, with the same market-leading reliability and ease of use – just with a smaller build volume (230 x 190 x 200mm or 9.1 x 7.4 x 7.9 inches).

MAIN FEATURES:

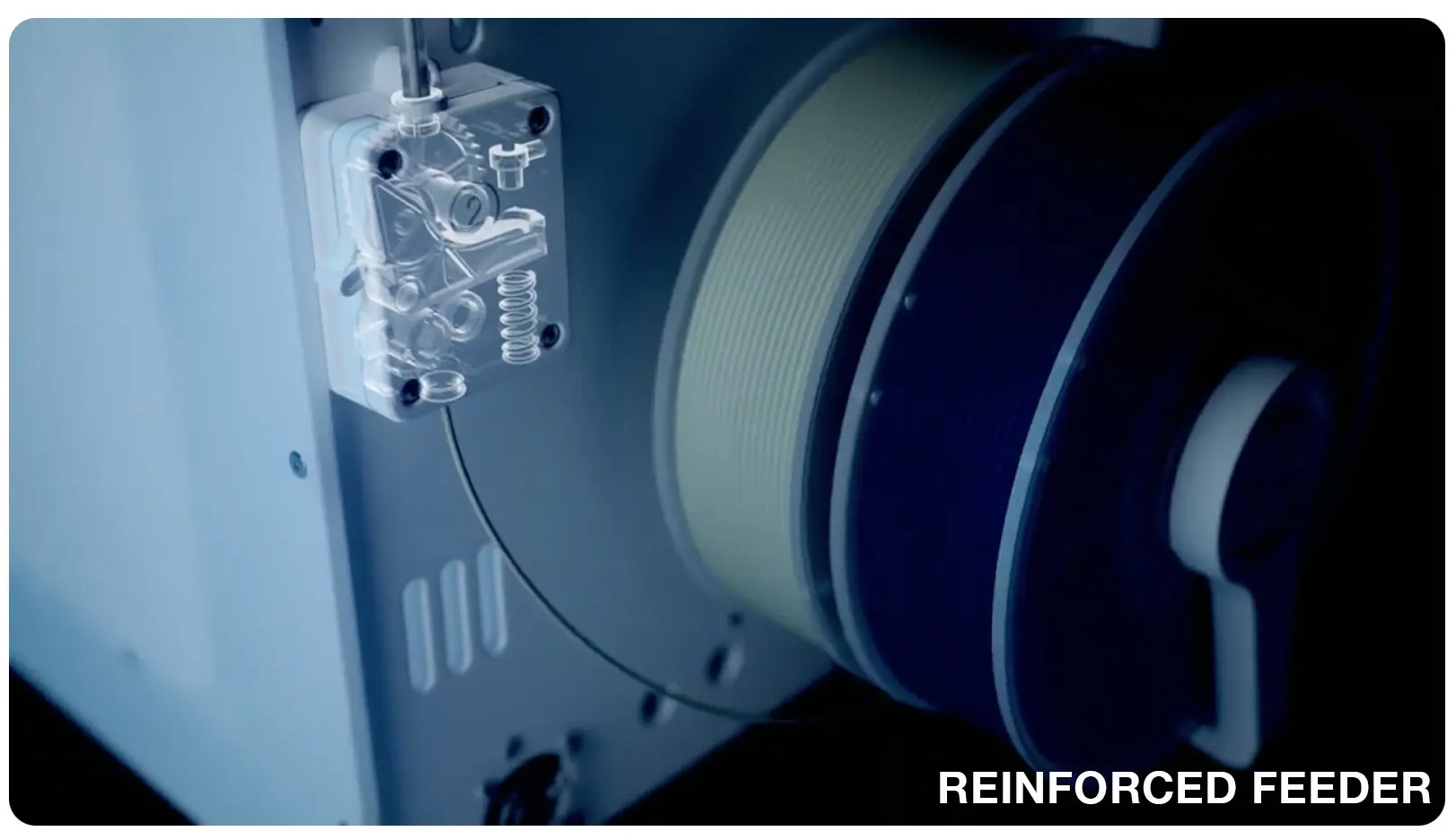

- REINFORCED FEEDER WHEELS: Made from coated, hardened steel. These enable abrasion-resistant 3D printing for high-strength parts using glass or carbon fibRE composites (when paired with Ultimaker print core CC Red)

- DUAL FILAMENT FLOW SENSORS: Increase your print success rate. If you run out of filament, they pause your print and notify you to add a new spool

- ADVANCED ACTIVE LEVELLING: Ensures easy and reliable first-layer adhesion. Begin a print job and get on with your work, thanks to precise build area probing and Z-height build plate compensation at the start of every print job

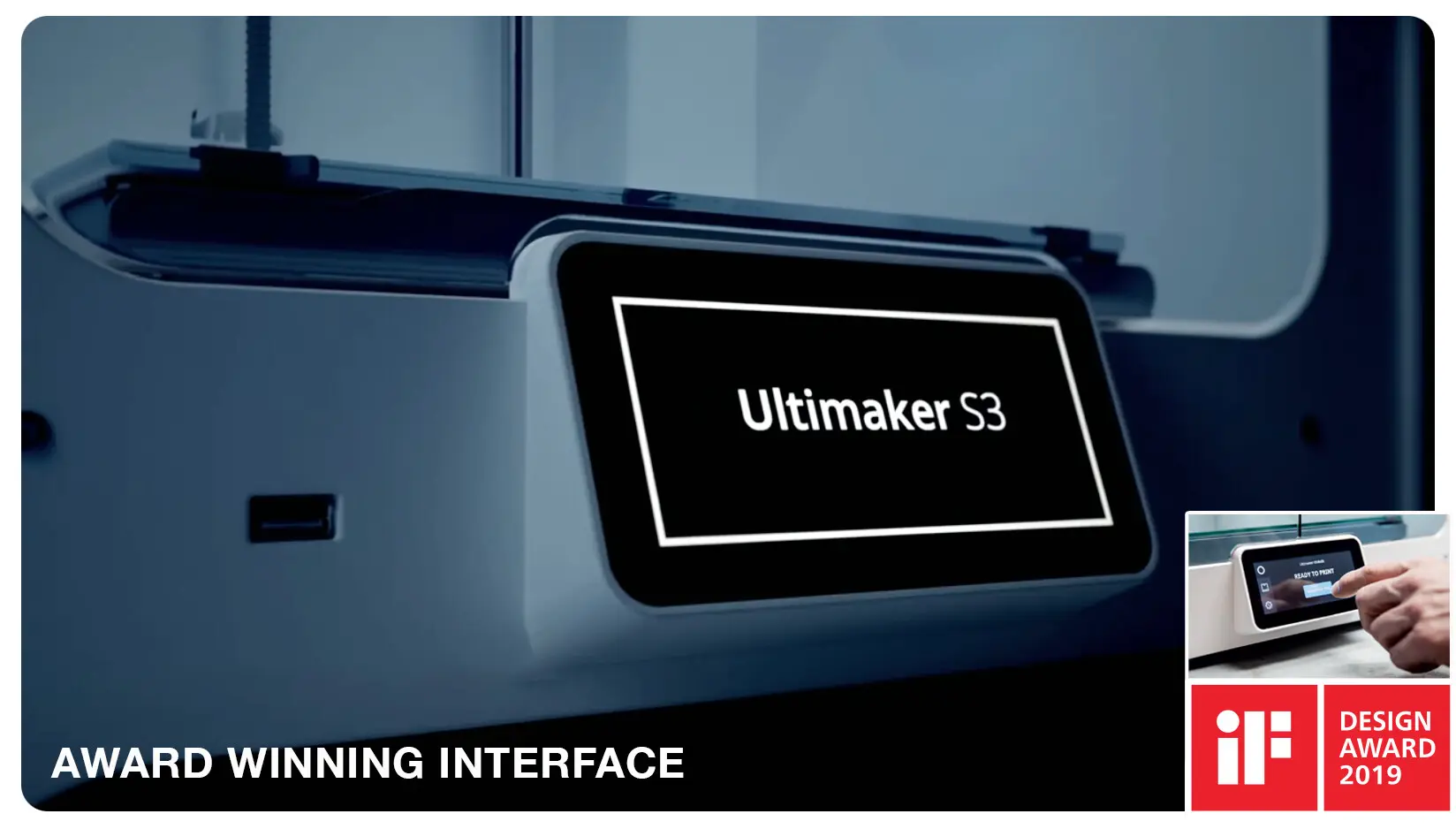

- TOUCHSCREEN: Effortless, intuitive operation via a touchscreen interface

- HIGH-ACCURACY STEPPER DRIVERS: Taken directly from the Ultimaker S5. These high-precision drivers are quieter than the Ultimaker 3 and run more reliably

- NETWORK CONNECTIVITY: Via Wi-Fi or Ethernet, print remotely over the cloud with added security

- RIGID PRINTER FRAME: Reduces small vibrations (or ringing) while printing to improve overall print quality

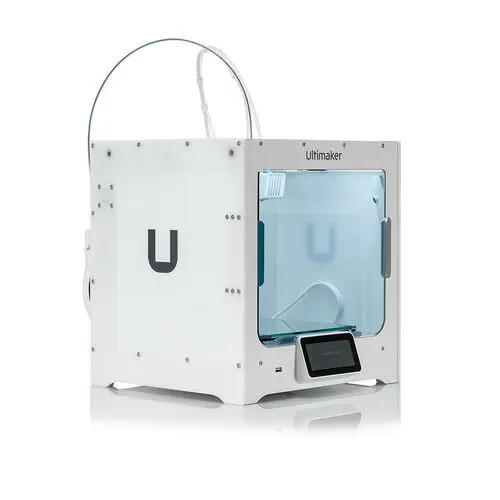

- SINGLE GLASS DOOR:With a magnetic latch provides a more controlled build environment to reduce the risk of warping or delamination

- OPTIMISED INTERNAL DESIGN:Allowing both dual extrusion nozzles to reach the whole build area, while maintaining a high build-volume-to-size ratio

- INTERNAL POWER SUPPLY:Removes the need to make space for a power brick. It also makes the setup process easy across all S-line 3D printers

The Ultimaker S3 delivers professional-grade 3D printing performance in a compact footprint. Designed for both desktop and industrial applications, it offers the same core specifications as the Ultimaker S5, making it ideal for product development, manufacturing aids, prototypes and end-use parts.

Reliable, Award-Winning Performance

Part of Ultimaker’s award-winning line of 3D printers, the S3 is renowned for its robust construction, reliability and user-friendly design. Built for continuous 24/7 operation, it ensures consistent, high-quality prints with precision and efficiency, helping you maintain productivity without interruption.

Open Material System for Maximum Flexibility

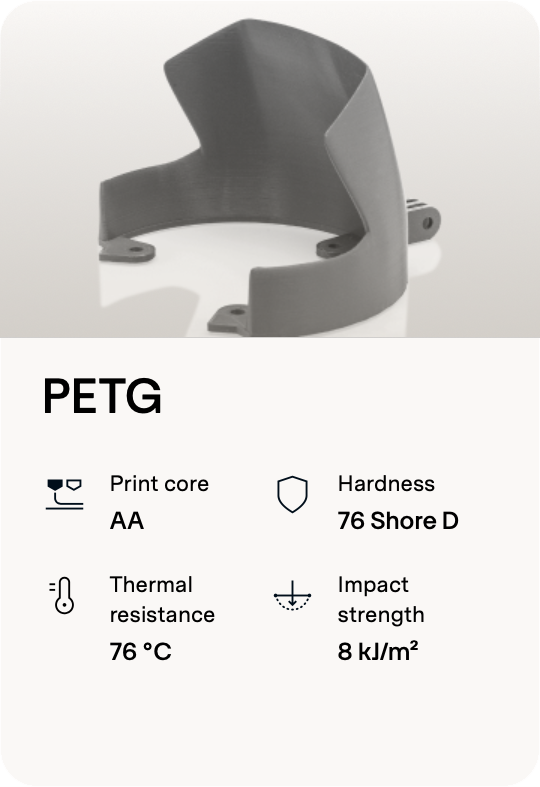

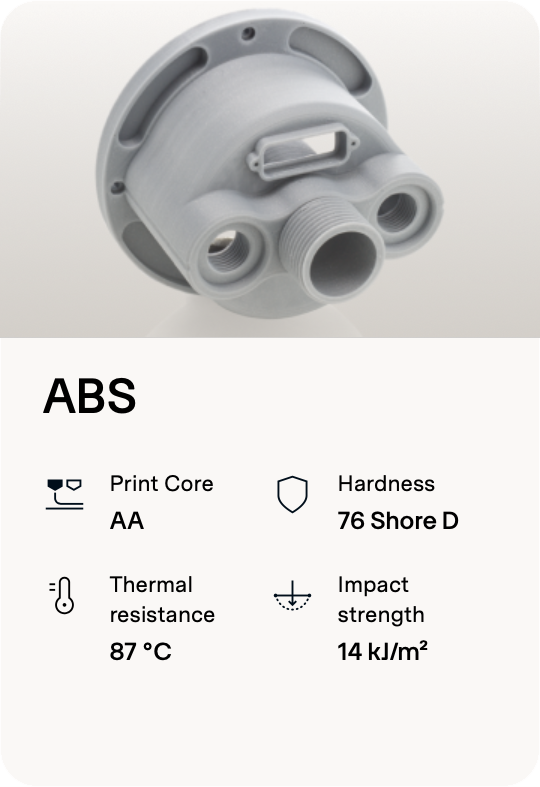

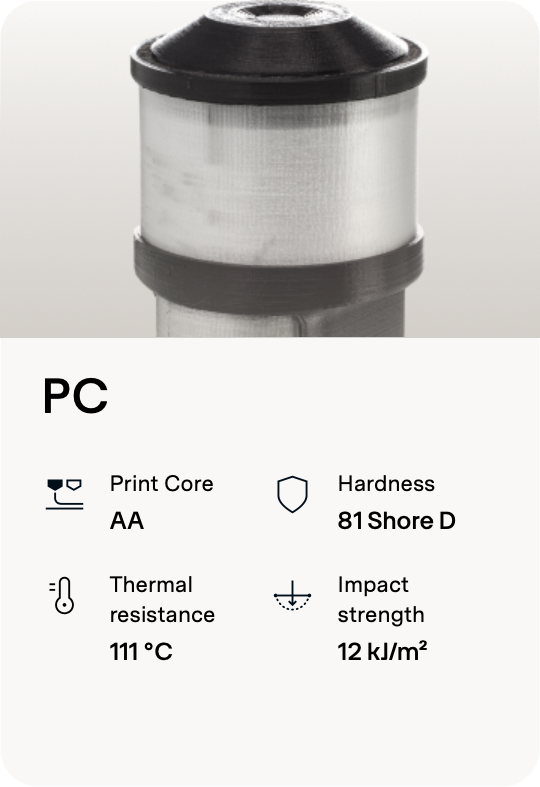

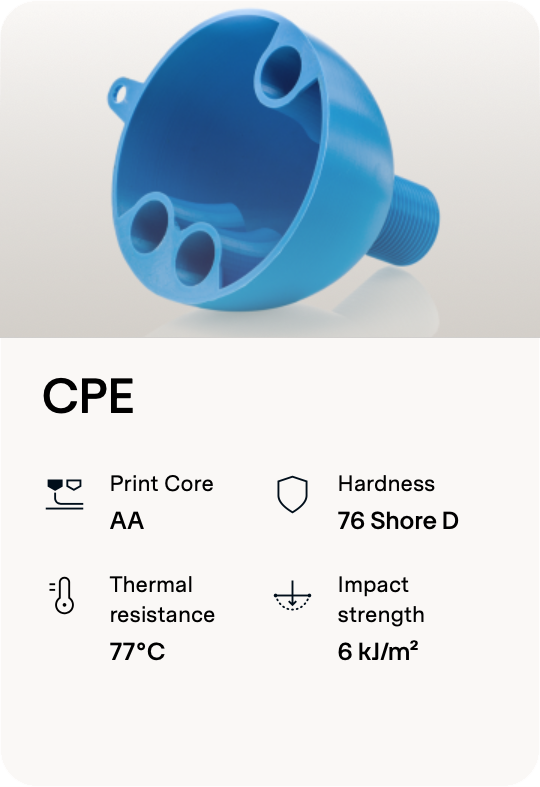

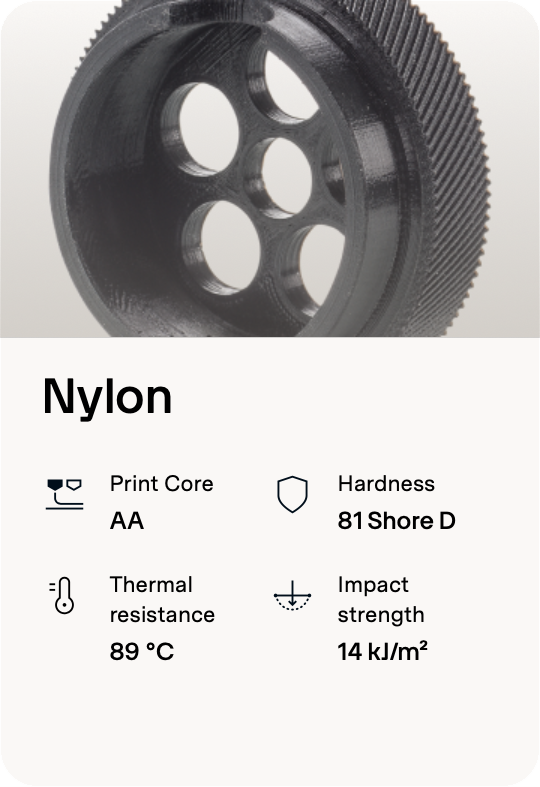

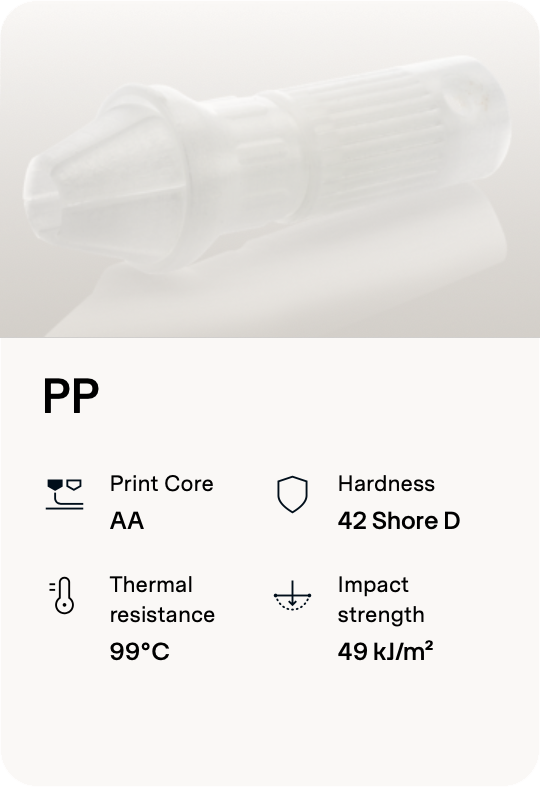

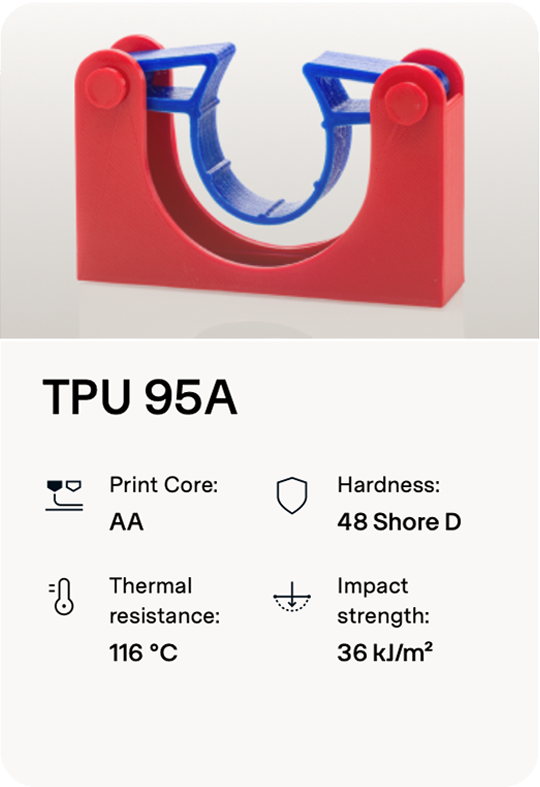

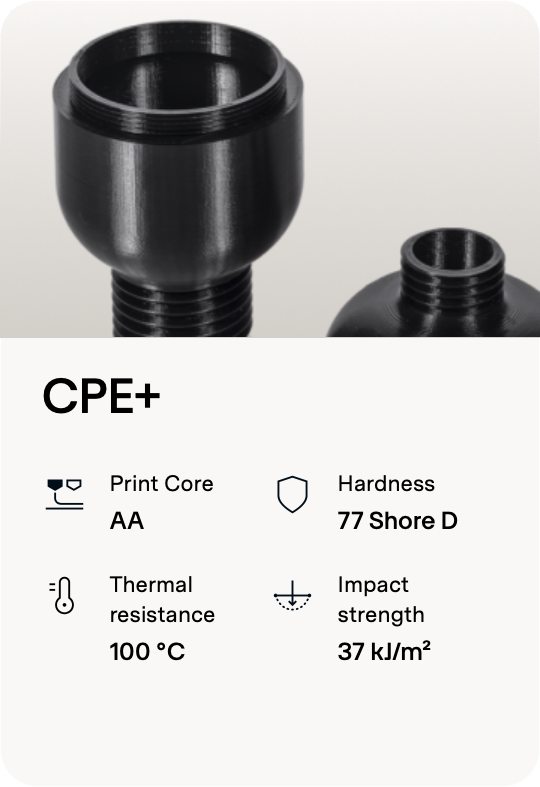

The open filament system allows you to use a wide range of materials to match your specific project needs. Choose from filaments that offer heat resistance, chemical durability, wear resistance or flexibility. This freedom enables you to fine-tune mechanical and aesthetic properties for every print.

Seamless Workflow with Ultimaker Cura

Ultimaker Cura software integrates effortlessly into any workflow, giving you full control over your printing process. Through the Ultimaker Marketplace, you can access a range of plugins that expand functionality, allowing you to customise and optimise your 3D printing experience.

Global Support and Local Expertise

Ultimaker’s global network of service partners offers installation, training, and maintenance in your local language and time zone. This ensures every user benefits from professional support and guidance tailored to their needs, no matter where they are in the world.

Intuitive Touchscreen Interface

The Ultimaker S3 features a bright 4.7″ (11.9 cm) touchscreen, the same award-winning interface found on the S5. Recognised with the 2019 iF Design Award, this intuitive display guides you through setup, navigation, and maintenance with ease.

Smart Dual Filament Flow Sensors

Revolutionise your workflow with dual filament flow sensors that monitor material usage in real time. If a spool runs out, printing automatically pauses and alerts you to replace it—preventing failed prints and ensuring a 100% success rate for complex projects.

Built for Strength and Precision

Engineered for demanding applications, the Ultimaker S3 delivers exceptional accuracy and strength. When combined with the Ultimaker print core CC Red, it can print with glass or carbon fiber composites to produce durable, industrial-grade parts that meet the needs of sectors such as aerospace, automotive and engineering.

Professional Results, Compact Design

From the design studio to the factory floor, the Ultimaker S3 offers the perfect balance of size, speed, and strength. Compact yet powerful, it’s the go-to solution for professionals who demand precision, reliability and versatility in every print.