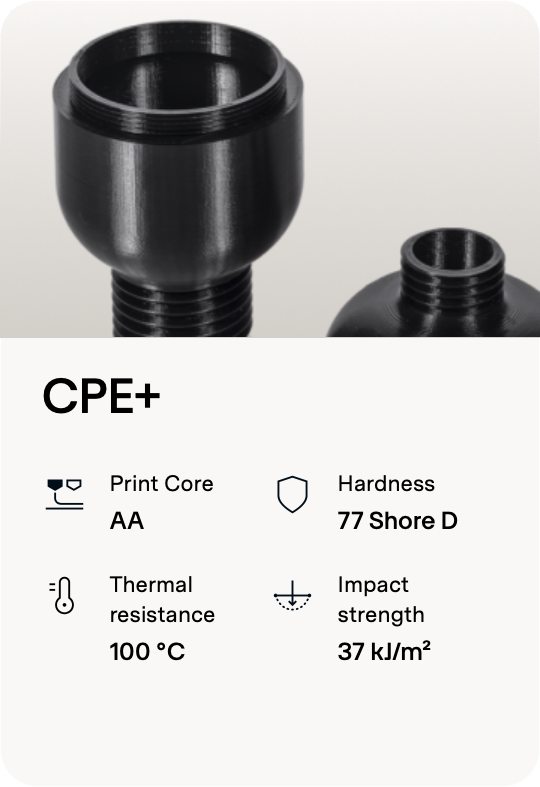

UltiMaker S-Series CPE+ Black 700g Filament (1644): CPE+ has a higher impact resistance than CPE, which makes it suitable for applications where toughness of the object is key. CPE+ is primarily used for functional prototyping and modeling. It has greater thermal resistance than CPE, and therefore parts printed in CPE+ can be used at temperatures up to 100 °C without deforming. This spool is approximately 90m in length.

With increased toughness compared to regular CPE, CPE+ is an extremely durable 3D printing material for functional prototypes that need to stand up to real-world use. UltiMaker CPE+ has properties that are ideal for custom mechanical parts that need high chemical resistance.

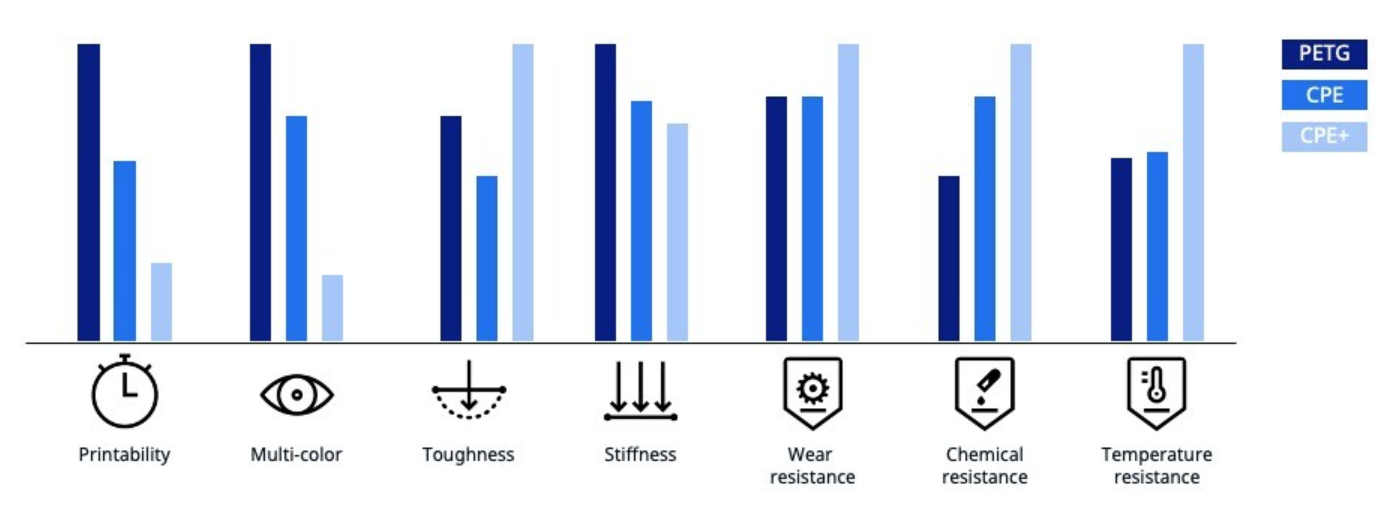

While both CPE and CPE+ share similar performance characteristics, CPE+ offers additional advantages. Notably, it boasts higher temperature resistance and increased impact strength, making it an excellent choice for applications where these specific attributes are crucial. Whether opting for CPE or CPE+, users can rely on these co-polyester materials to deliver durability and reliability in the creation of functional and robust 3D-printed components.

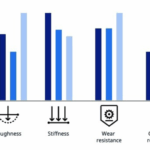

PERFORMANCE COMPARISON: PETG / CPE / CPE+

KEY FEATURES:

- UltiMaker CPE+ has properties that are ideal for custom mechanical parts that need high chemical resistance

- Dimensional stability over long periods of time

- Low odour and low ultrafine particle emissions and gases

- Ideal for short-run manufacturing and functional prototype

- CPE+ features a temperature resistance of up to 100° C when compared to CPE, which is only resistant up to 70°C

APPLICATIONS:

- Custom components that need to withstand high temperatures

- Visual and functional prototyping

- Fit Testing

- Short-run manufacturing