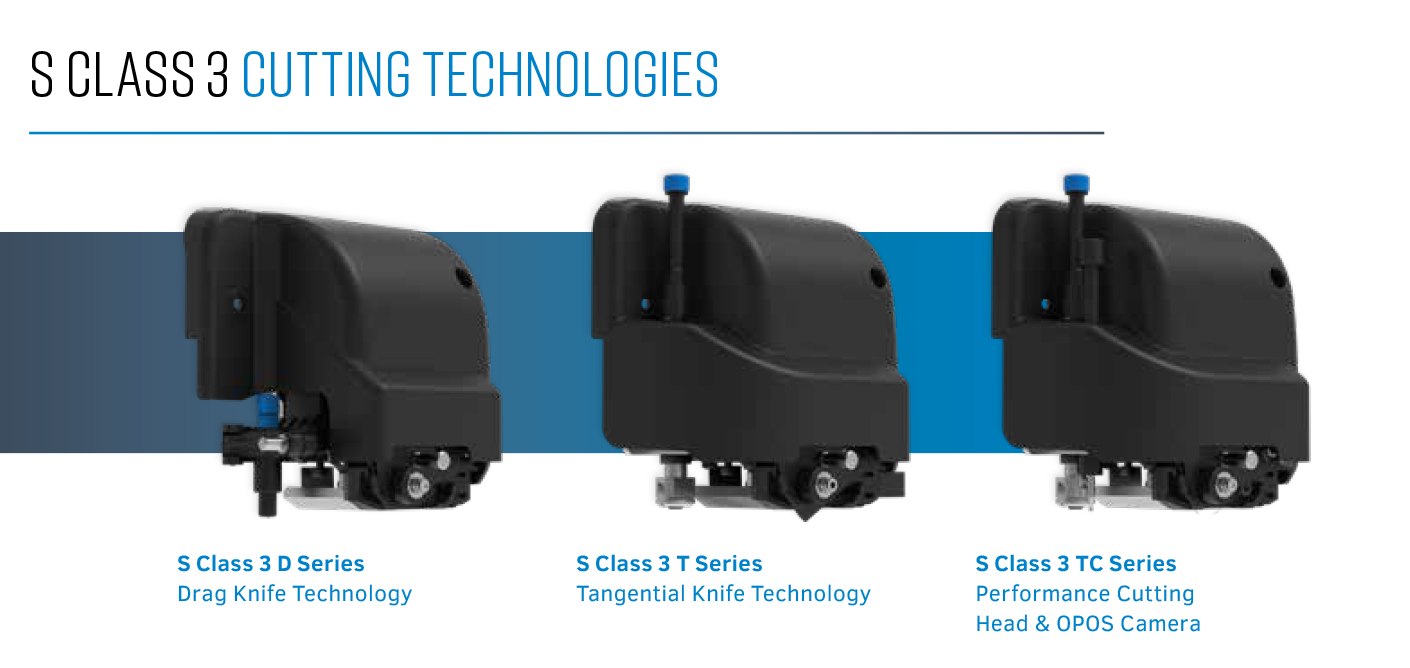

Summa is proud to announce a brand-new vinyl cutter product line. The Summa S Class 3 is a state-of-the-art device designed for professional users who demand top performance in their cutting applications and want to explore new opportunities.

Summa S Class 3 S160 TC-Series 63” 1600mm Cutter OPOS-PRO CAM S3TC160: Introducing the TC line, featuring the apex of cutting head technology in the new S Class 3 Roll Cutter Series. Engineered with unparalleled precision, the S3TC75 and S3TC160 models boast cutting-edge capabilities, enabling dual-tool functionality for FlexCut and kiss-cut operations alongside creasing or drawing tasks, all seamlessly integrated without the need for tool changes. The creasing capability lends itself perfectly to short-run applications, making it ideal for crafting bespoke gadgets for events or corporate entities in folding carton.

The S Class 3 TC models also introduce an enhanced camera system, significantly elevating performance standards. With automatic data processing directly within the cutter, mark registration achieves unprecedented speeds. Paired with our robust True Tangential Cutting Technology and knife pressure capabilities reaching up to 1000 grams, these models are meticulously engineered to deliver unparalleled cutting precision and excellence.

The new range also Introduces the Smart Object Sorting feature, engineered to streamline efficiency by automatically determining the optimal starting point for cutting objects with precision and consistency. Complementing this innovation is Summa’s exclusive Smart Paneling function, which enhances cutting accuracy and simplifies post-processing tasks. For instance, by setting paneling to 18 inches, all objects within this specified range are seamlessly cut in a single operation.

The TC versions are available as a factory upgrade for Summa S Class 3 T75 & T160. Please ask if this is a route you are considering!

The Summa S3 75 stands as the compact powerhouse within the new S3 series, meticulously crafted to meet the diverse requirements of both novices and industry veterans alike. Boasting a capacity to effortlessly process media measuring up to 74cm (with an additional 7cm allowance in oversized mode), this cutter is an ideal companion for flex, flock, and label-cutting enthusiasts, ensuring precision and efficiency in every task.

KEY FEATURES:

- Features Dual Head technology: knife + fibre pen or knife + creasing tool

- Advanced cutting technology

- Media width up to 168 cm

- Ergonomic design

- User-friendly features

- Latest alignment method

- Legendary tracking performance

- Connectivity options

- Summa GoSign software

- Unique True Tangential cutting technology

- Indicator light

- Mark registration about 10 times faster than any other light sensor

- Custom camera profile to process challenging media types

- Barcode functionality for automation

- Job segmentation to preserve the best tracking performance

- Available as a factory upgrade for Summa S Class 3 T75 & T160

G PERFORMANCE MODE (OPTIONAL):

Engaging this mode on the S Class 3 roll cutters can significantly enhance production speed by up to 40%, contingent upon the nature of the cutting task. This acceleration is particularly pronounced during swift registration mark detection and when processing wider substrates. Consequently, default jobs are executed at a notably accelerated pace. G-performance is tailored for users seeking to maximize yield, facilitating the processing of jobs at higher than average speeds.

EASE OF USE:

Experience enhanced user-friendliness with a status bar illuminated in blue, green, and red, providing intuitive feedback at a glance. Easily pinpoint adjustable components with their distinctive blue coloring. Complementing this feature is a thoughtfully positioned tool tray at the rear, ensuring efficient and seamless operation.

LARGER MEDIA ROLL:

The media roll capacity of the cutter has been enhanced to accommodate a diameter of 20cm, with support for a minimum roll weight of 45kg. This upgrade proves immensely advantageous for print and cut applications, particularly those involving laminated vinyl, ensuring smoother and more efficient operations.

SERVO-POWERED ROLL-UP SYSTEM (S3 140 & S3 160):

Upon completion of a job, the system will meticulously roll up the artwork, preparing the machine seamlessly for the next task. The integrated panelling feature intelligently divides lengthy runs into shorter, consecutive tasks, enabling the cutting of entire rolls without requiring constant supervision and delivering neatly rolled-up output for added convenience.

APPLICATIONS:

LARGE SIGNS:

The Summa S Class 3 opens the door to commanding attention with your signage endeavors. Whether you’re crafting dynamic floor graphics, impactful wall designs, attention-grabbing window stickers, or precise lettering, this machine executes each task with finesse and precision.

Taking your message on the move? Summa roll cutter ensures your vehicle graphics demand attention wherever they roam.

Looking to maintain privacy? The S Class 3 seamlessly transforms your windows into promotional showcases while preserving confidentiality from within. And for indoor attention-grabbers like totems and interior advertising, the S Class 3 handles them with effortless proficiency.

SMALL TEXT & INTRICATE DESIGNS: PRECISION AT ITS BEST:

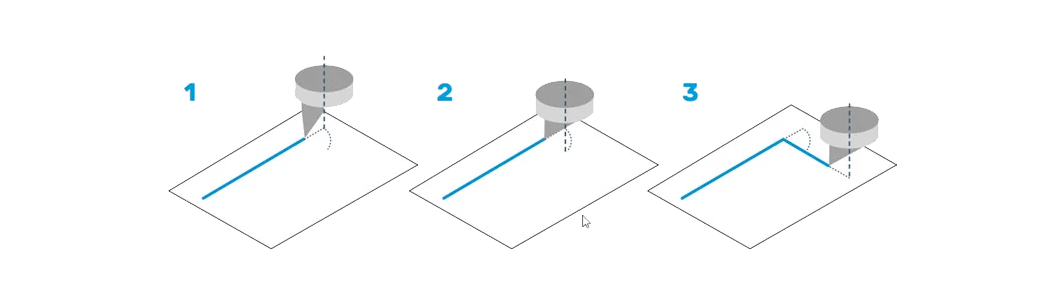

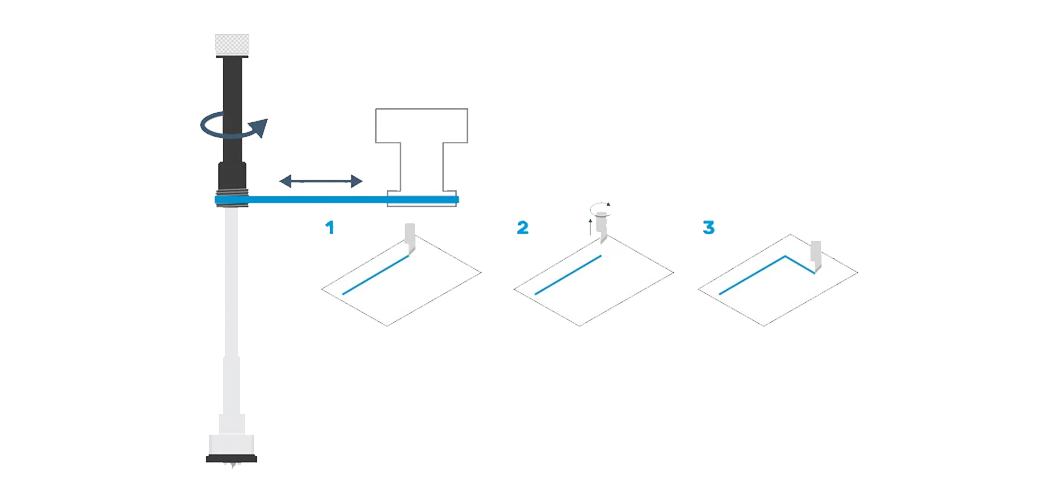

The Summa S Class 3 stands as the ultimate solution for mastering intricate designs and small letters with unparalleled precision, thanks to Summa’s revolutionary Tangential cutting technology. Unlike conventional drag knives, this innovative system elevates and repositions the blade in corners, resulting in impeccably sharp and precise cuts.

But its superiority doesn’t end there – equipped with Smart Object Sorting, the S Class 3 intelligently selects the optimal starting point for cutting, while Smart Panelling ensures efficient cutting of all objects within a designated range.

From flawlessly cut keychains and magnets to precise small signage like nameplates, directional signs, and room numbers, this machine excels across a spectrum of applications. Labels and tags, essential for both product branding and organizational purposes, achieve perfection with ease. And for enthusiasts of custom apparel, the S Class 3 delivers impeccable results, whether it’s personalized T-shirts, hats, socks, and more.

EVERY TYPE OF STICKER IMAGINABLE:

Elevate your sticker game with the S Class 3! Revolutionising your print and cut workflows like never before, this machine introduces the groundbreaking FlexCut feature.

How does FlexCut transform your workflow? One length is fully cut through the material, while the other is scored halfway, creating a flawless tear-off line. This unique process ensures your material maintains rigidity during transport through the Summa cutter yet remains effortlessly removable from your designs afterward.

The creative possibilities are endless! Whether you’re crafting standard vinyl stickers, kiss-cut stickers, die-cut stickers, clear stickers, bumper stickers, holographic stickers, transfer stickers, or even window clings and wall/floor stickers, the S Class 3 handles each task with unparalleled precision and ease.

THICK, THIN & TOUGH MATERIAL:

The versatility of the S Class 3 extends beyond standard laminated vinyl. With its tangential cutting head, this machine can effortlessly handle an array of materials with non-standard thickness, unlocking a realm of cutting possibilities.

Thin materials encompass substances thinner than traditional sticker vinyl, such as car wraps, offering flexibility and precision in cutting. On the other end of the spectrum, thick and resilient materials, often overlapping with the aforementioned category, can reach up to 1.2mm in thickness, including laminated vinyl and folding carton. This breadth of compatibility expands the horizons of what you can achieve with the S Class 3, ensuring unparalleled adaptability across various projects and materials.

CREASING (TC MODELS ONLY):

Exclusive to Summa cutting plotters is the unique ability not only to cut but also to crease. With the innovative Performance Head, the S Class 3 can seamlessly execute both functions within the same job, eliminating the need for tool changes or machine pauses.

The creasing function is perfect for short-run applications. For example, to make exclusive gadgets for events or companies in folding carton..

The versatility of folding carton knows no bounds when paired with the S Class 3. Imagine producing high-quality restaurant menus or personalized greeting cards for special occasions. Short-run leaflets and folders are effortlessly achievable with the S Class 3’s precision. Furthermore, the machine enables the creation of custom-designed little boxes, perfect for holding small gifts or business cards.