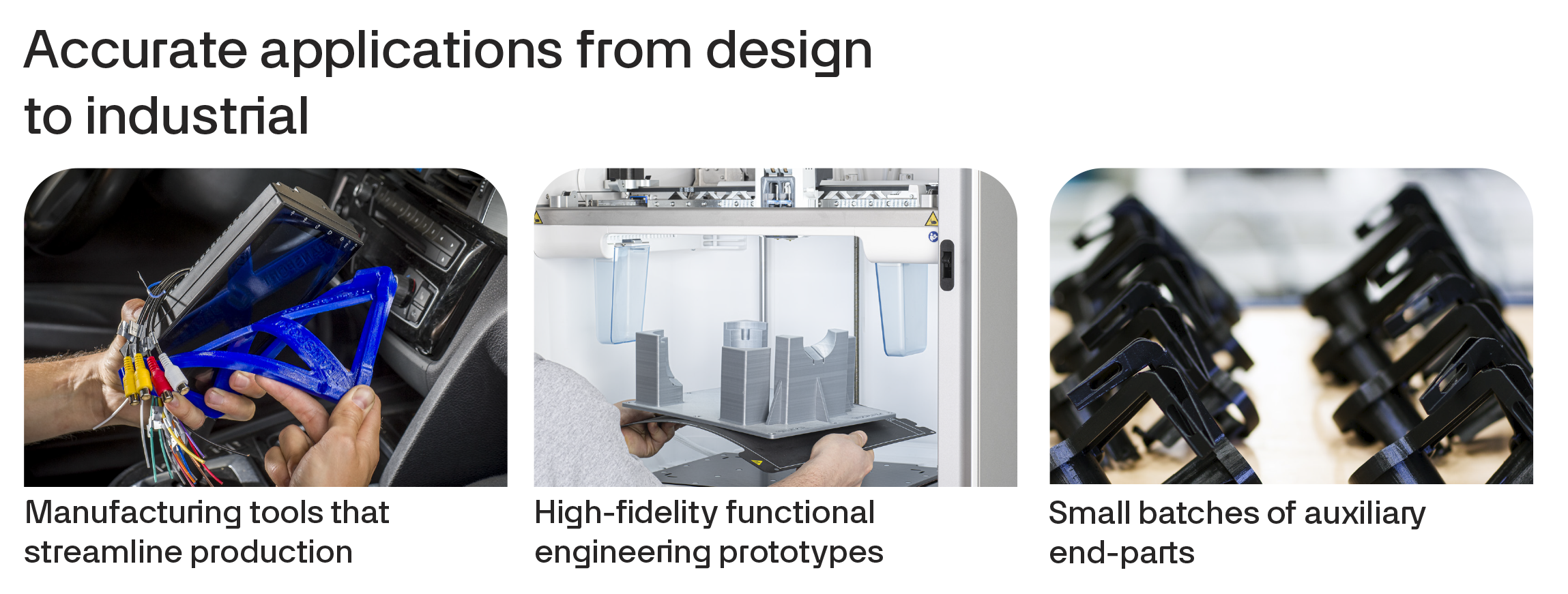

UltiMaker Factor 4 3D Printer (64-234991): Provides a complete industrial application solution, designed specifically for the seamless development, production and confident deployment of essential tools and machine components. When operational continuity is paramount, Factor 4 streamlines factory processes and minimises human-related inconsistencies. Its advanced features include dual material extrusion, support for engineering materials, and real-time print process reporting, ensuring unparalleled predictability and consistency.

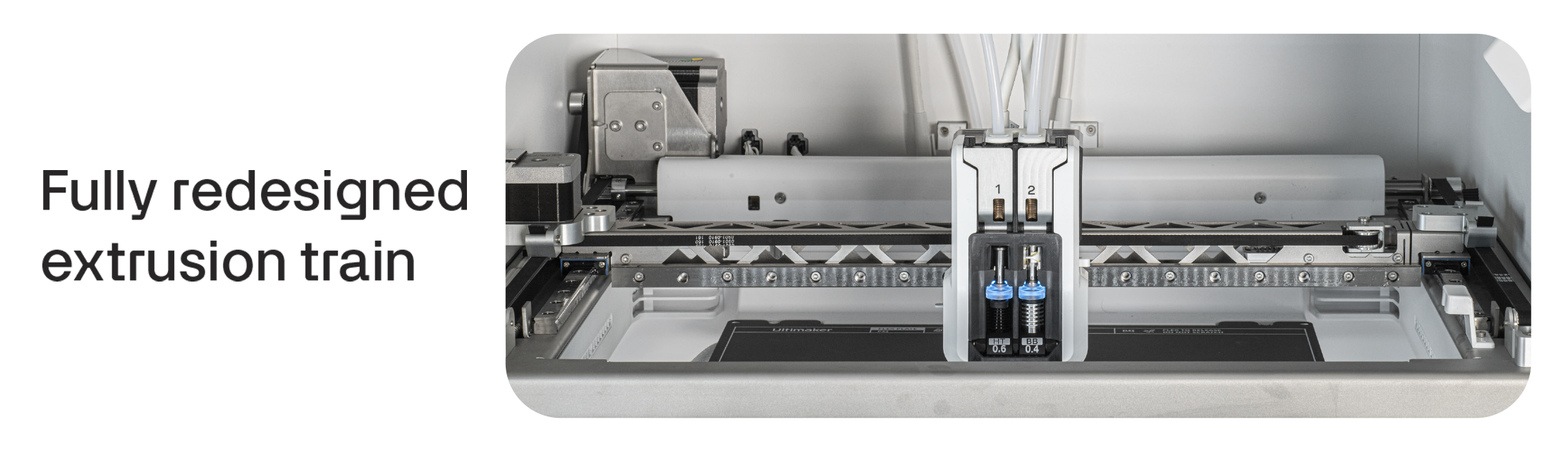

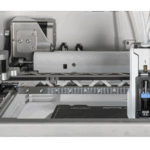

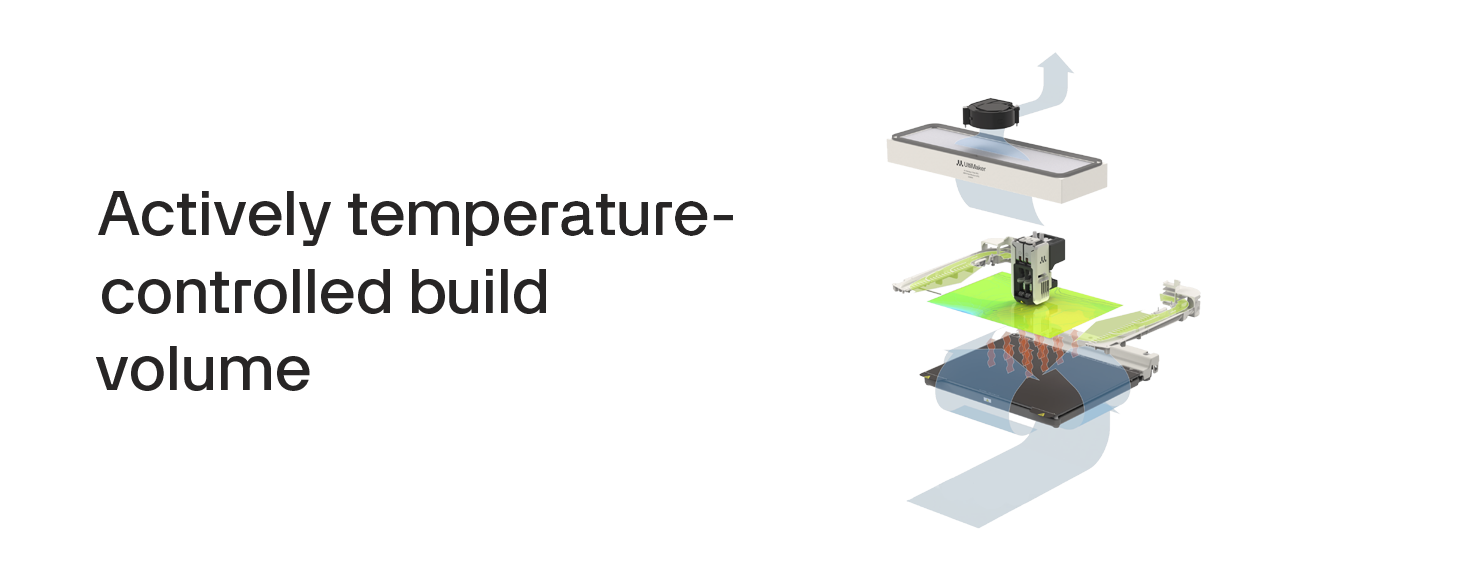

Factor 4 revolutionises manufacturing with its triple-insulated build chamber and direct dual extrusion capabilities, setting a new standard for efficiency. The automated material handling system guarantees filament quality, while the sturdy, temperature-controlled design ensures consistent output, even for intricate and demanding designs. It's the seamless, powerful upgrade your production workflows have been waiting for.

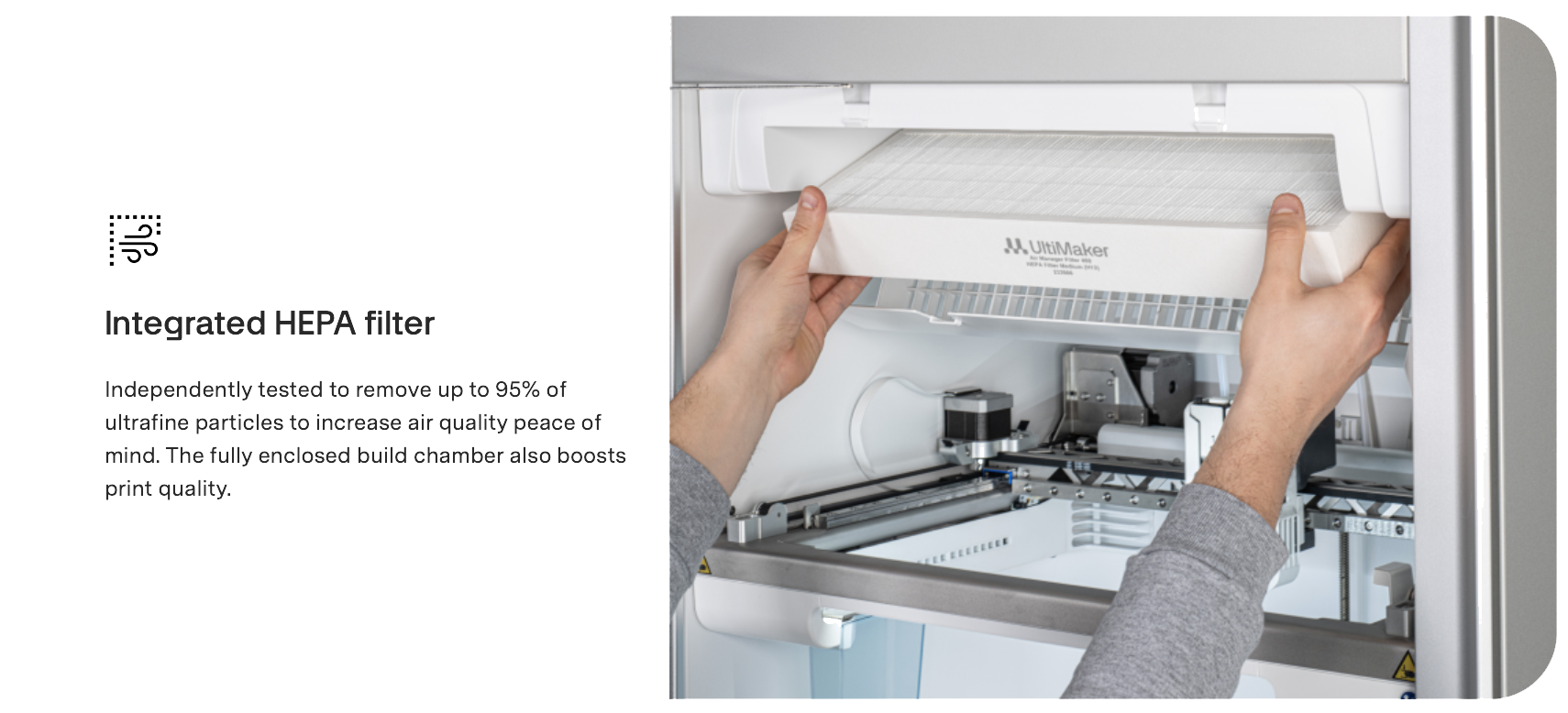

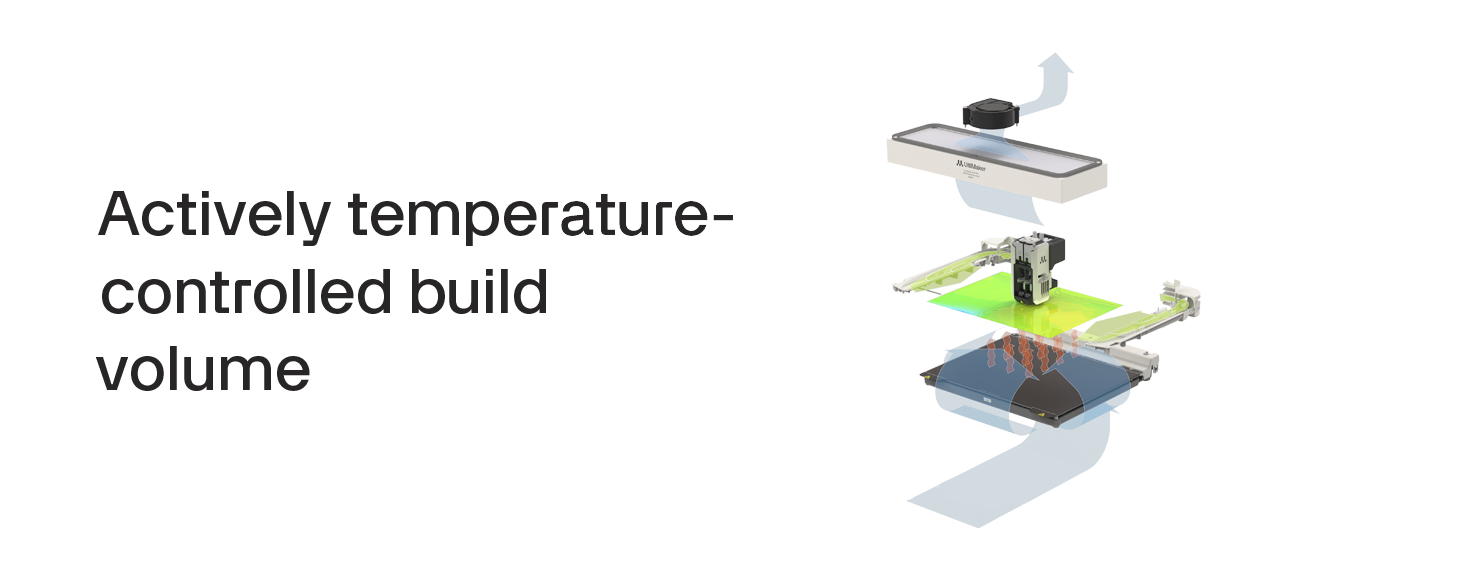

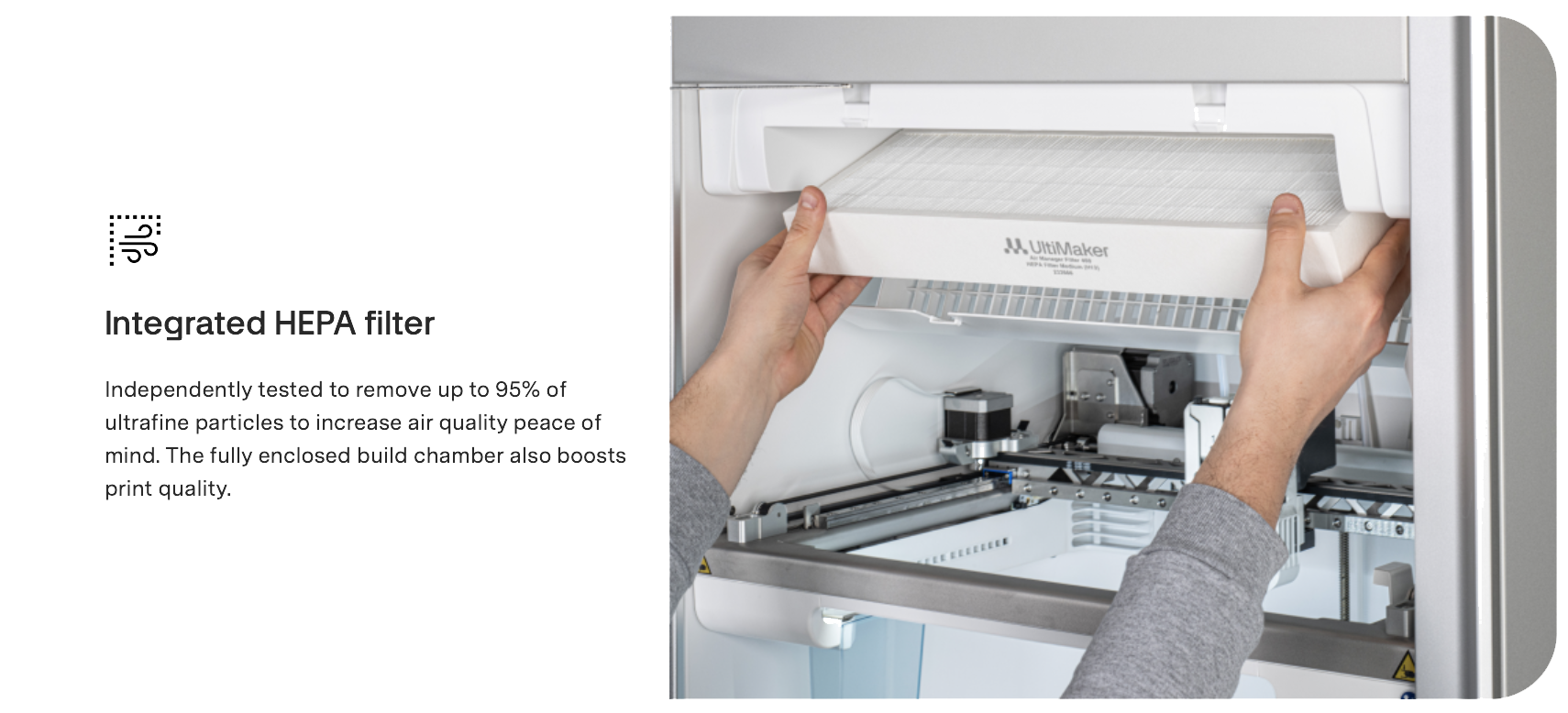

The UltiMaker Factor 4 is purpose-built for industrial environments, boasting a rugged construction crafted from steel, aluminum, and glass. Its versatile design allows placement in any location, supported by a triple-insulated and temperature-controlled build volume, along with an integrated HEPA filter for enhanced air quality.

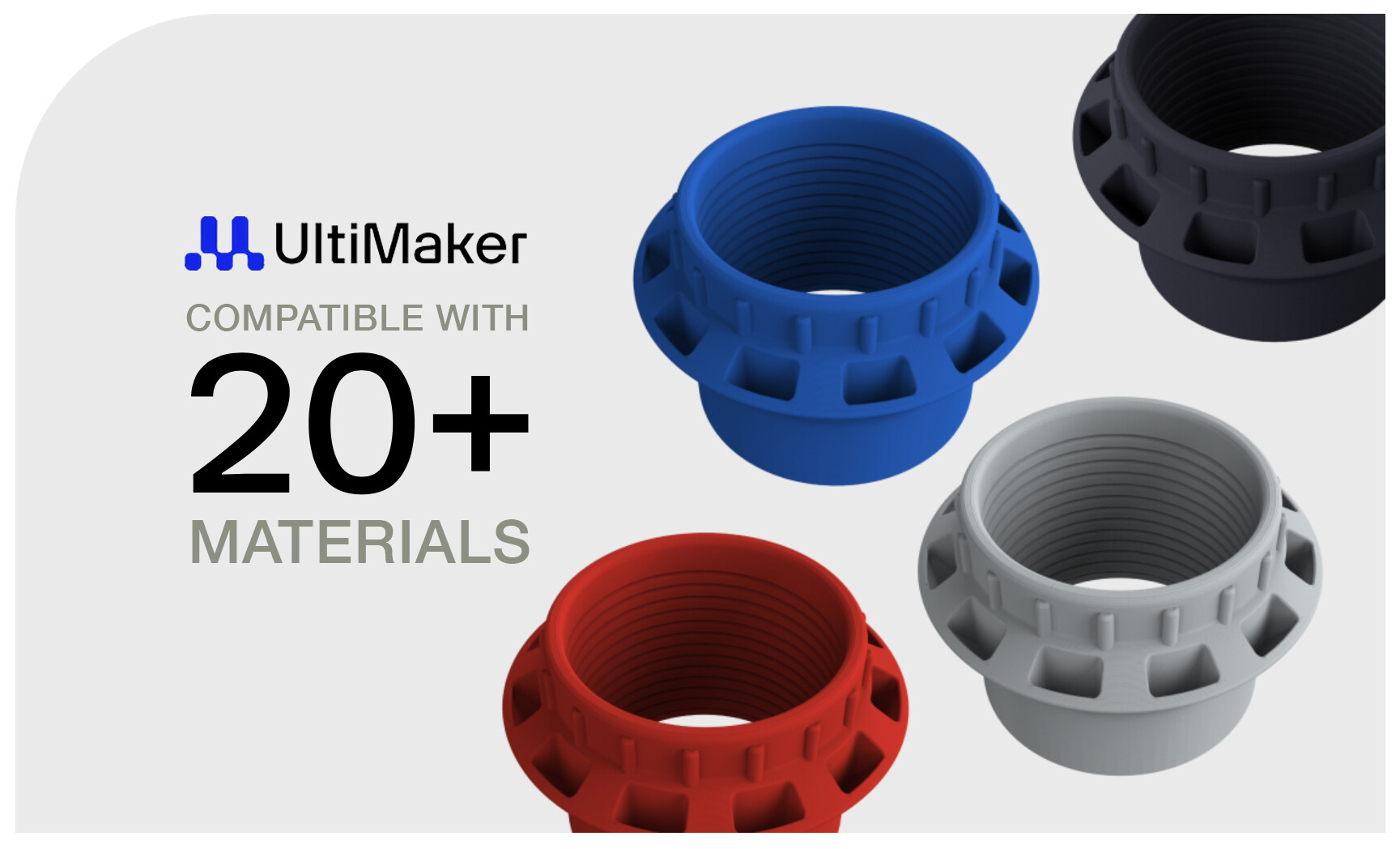

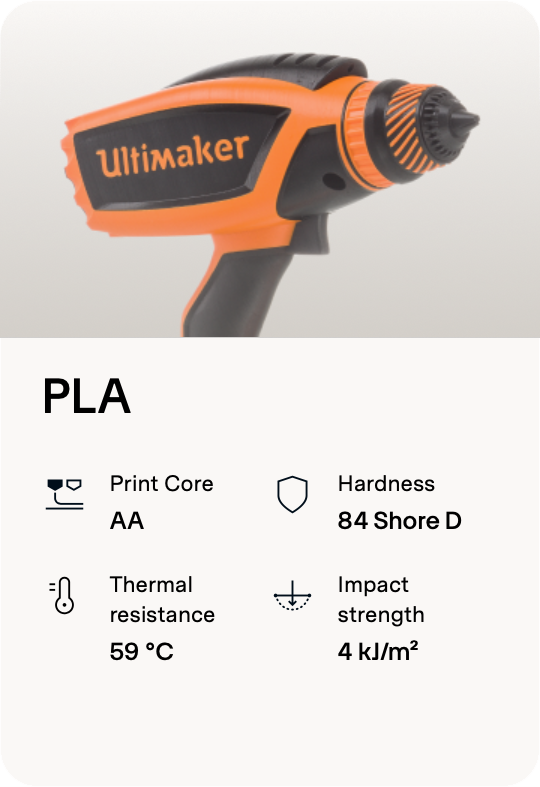

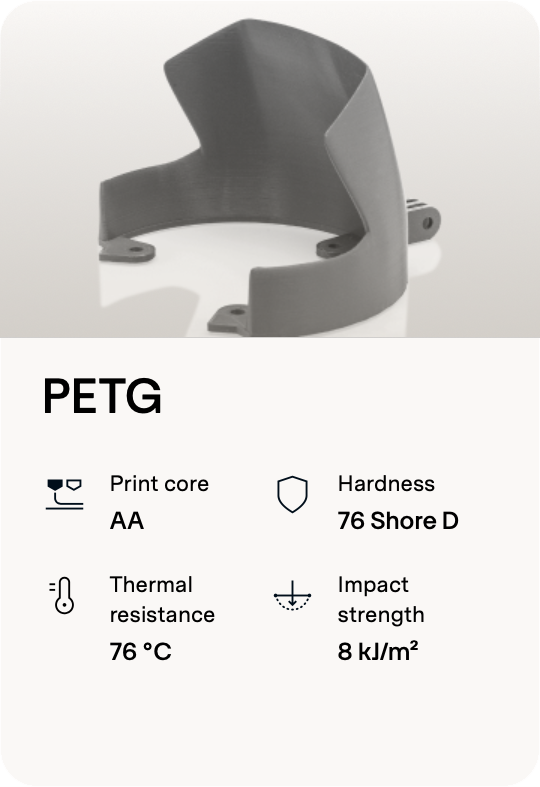

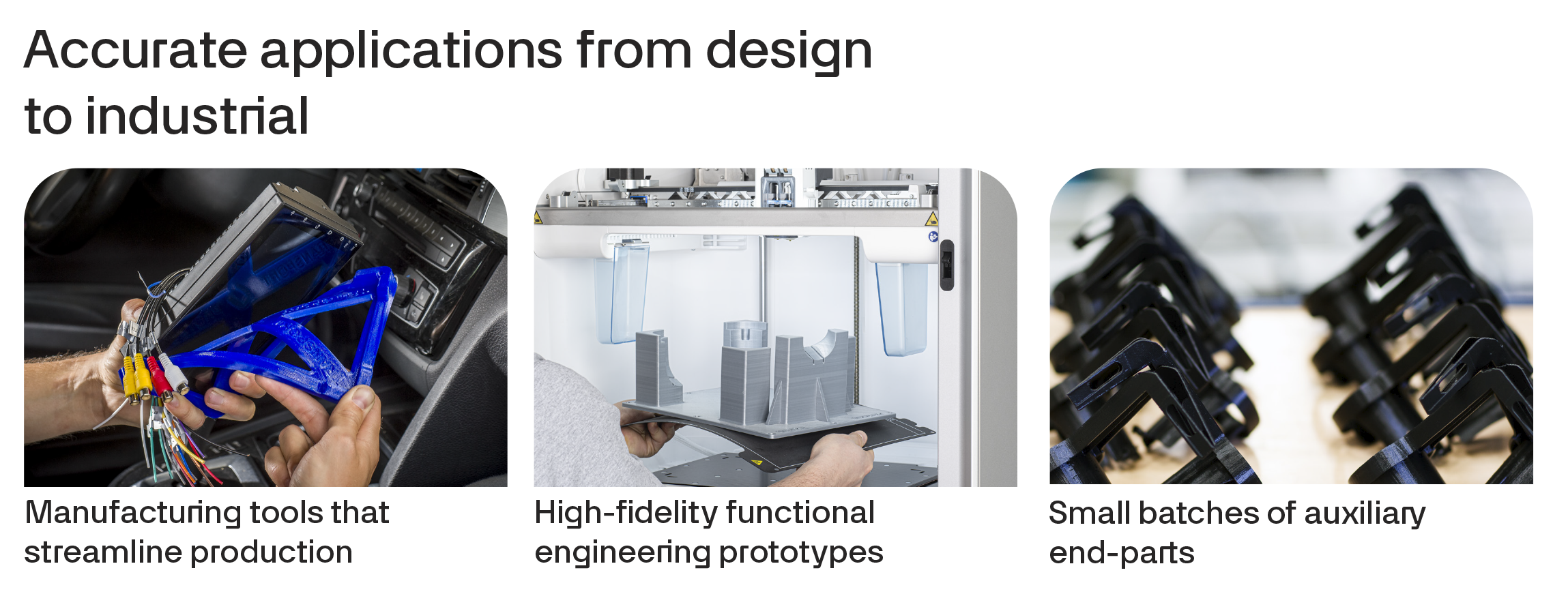

The precision to replicate functional parts across diverse engineering materials expedites testing and fosters innovation. Factor 4 boasts a low-emission, low-maintenance platform that guarantees safety even when unattended. Maintain complete control with access to over 400 Cura settings and comprehensive part validation tools.

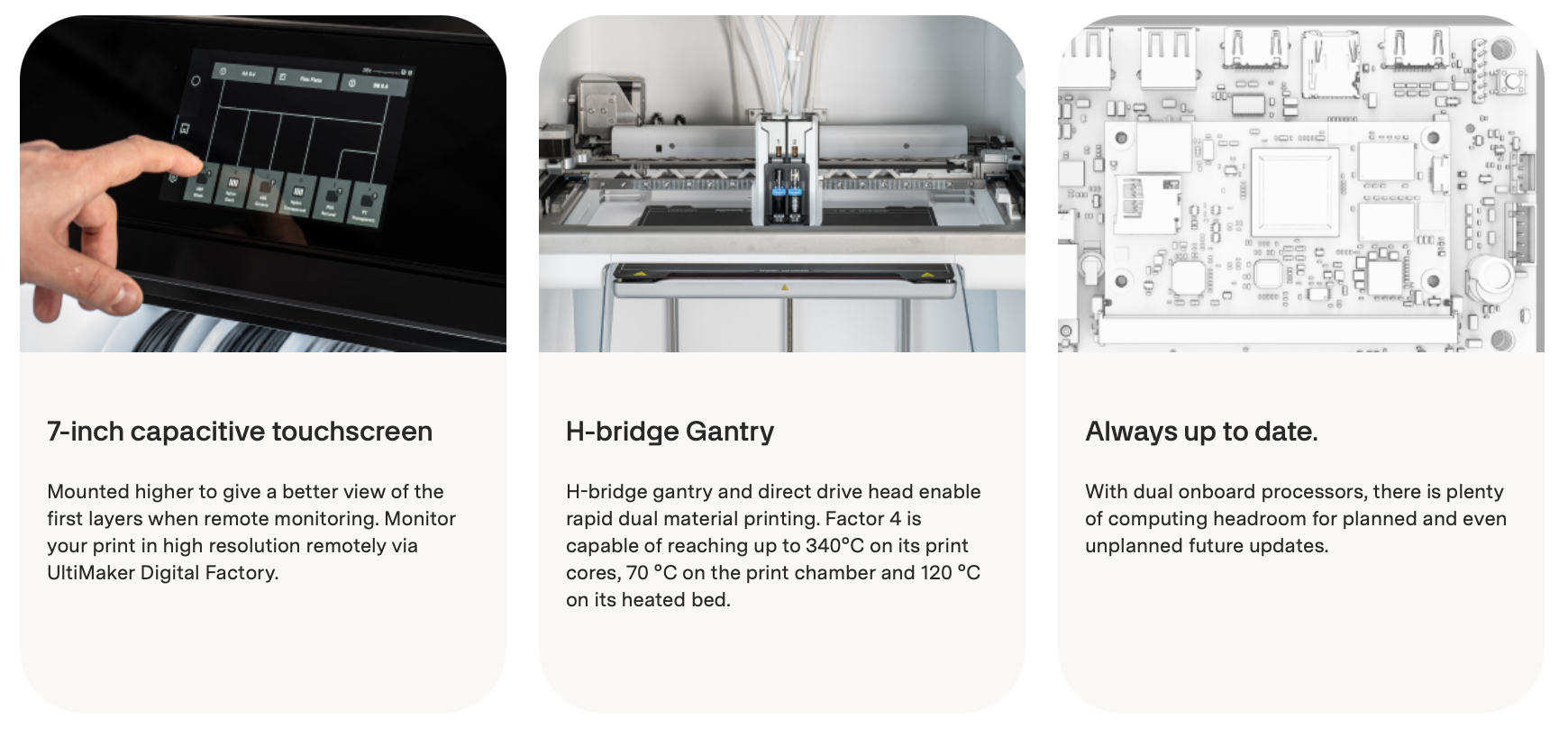

Factor 4 is packed with new features, including:

- OPEN SUPPORT FOR MORE ENGINEERING MATERIALS

- DIRECT DRIVE DUAL EXTRUSION

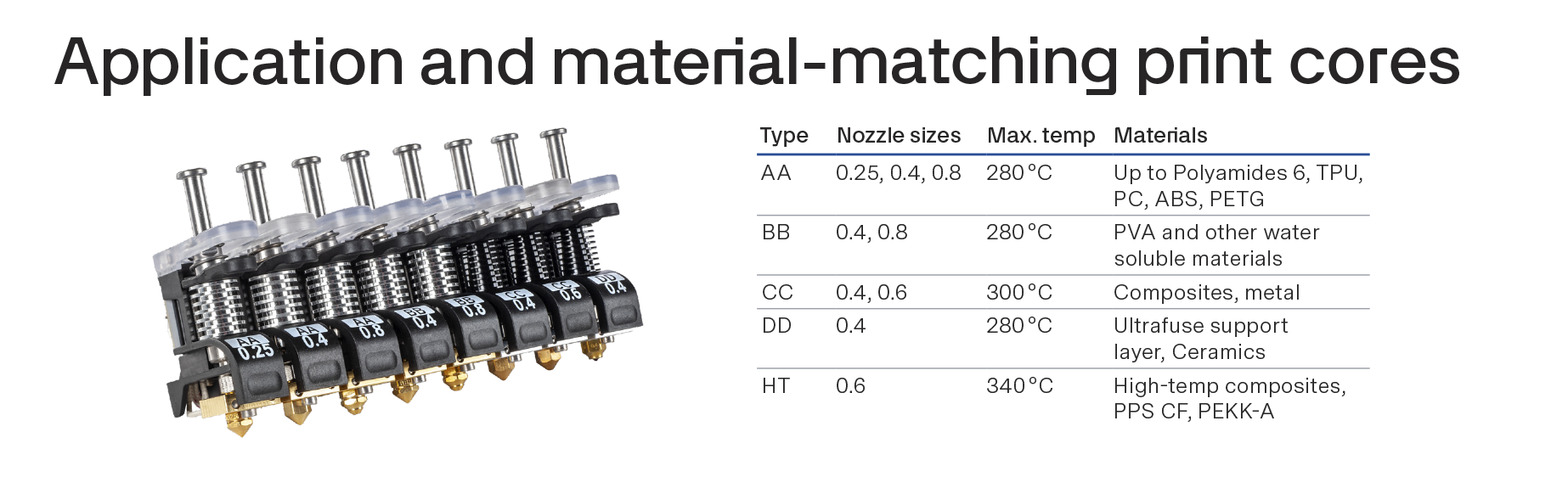

- HIGH TEMPERATURE RANGE UP TO 350°C

- AUTOMATED MATERIAL HANDLING WITH LOW-HUMIDITY STORAGE

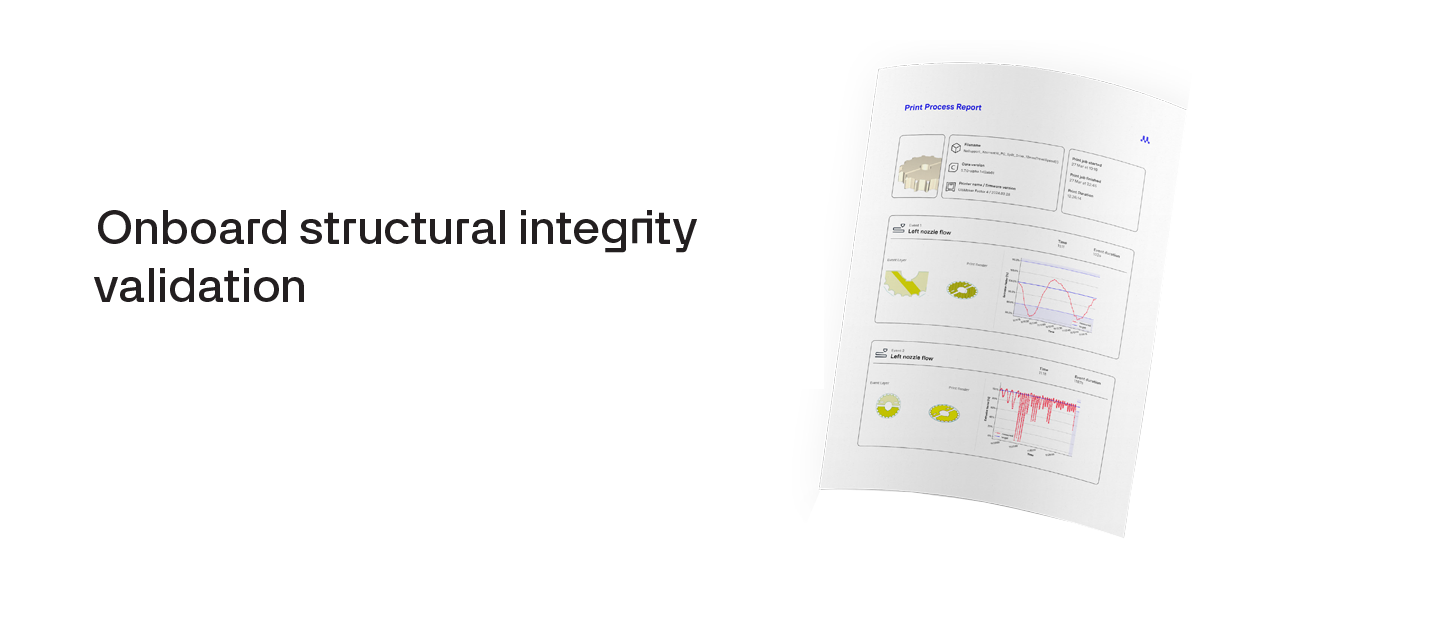

- ONBOARD PRINT PROCESS REPORTING

Factor 4 ensures consistent and verifiable part quality, ideal for distributed production setups. With its H-bridge gantry, closed-loop feed control, and precisely controlled build plate temperatures, it achieves less than a 10% variance in extrusion rate and mechanical properties. Moreover, its repeatable dimensional accuracy batch after batch is maintained, with a maximum variation of just 5°C across the X and Y axes.

Introducing UltiMaker PPS-CF, an advanced high-temperature composite engineered for Factor 4, designed to replace intricate steel components. With a heat deflection temperature exceeding 230°C, it offers exceptional chemical resistance and flame retardancy (UL94 V0), rendering it a versatile and reliable option for the most challenging of applications.

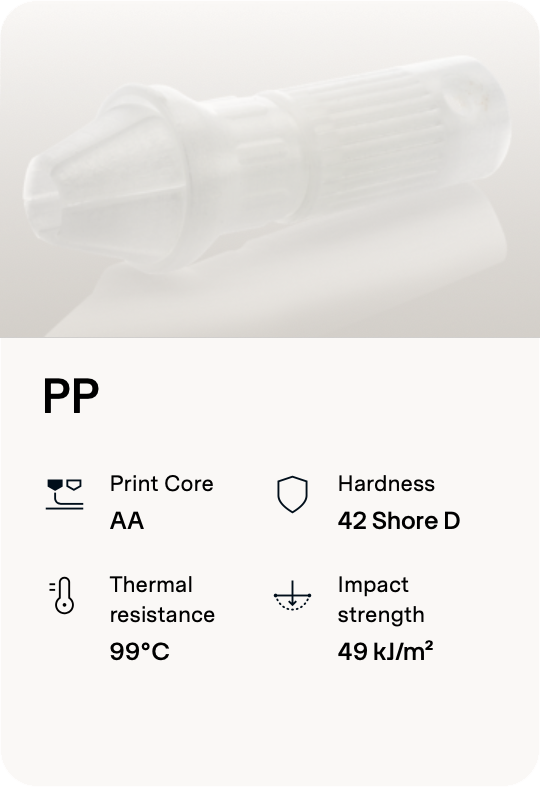

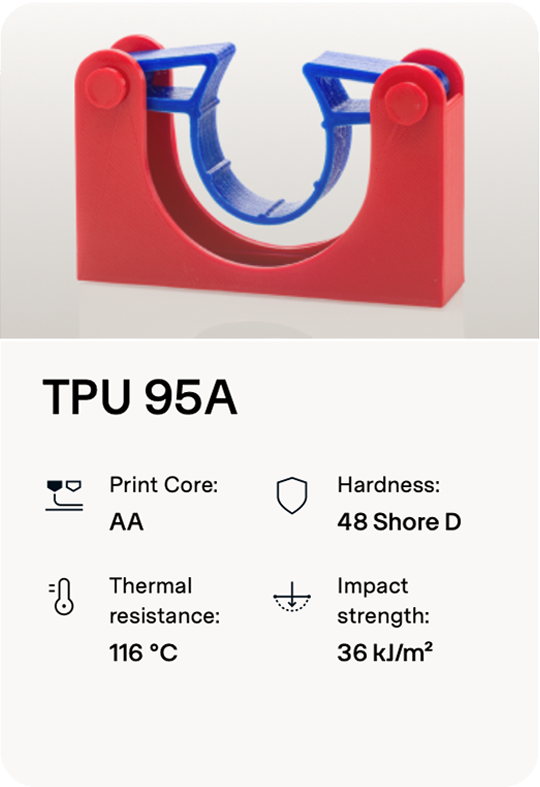

- Factor 4's compatibility with flexible materials down to Shore 70A ensures dependable protection for parts against damage, enabling the creation of gaskets, seals, and shock absorbers with precision and reliability.

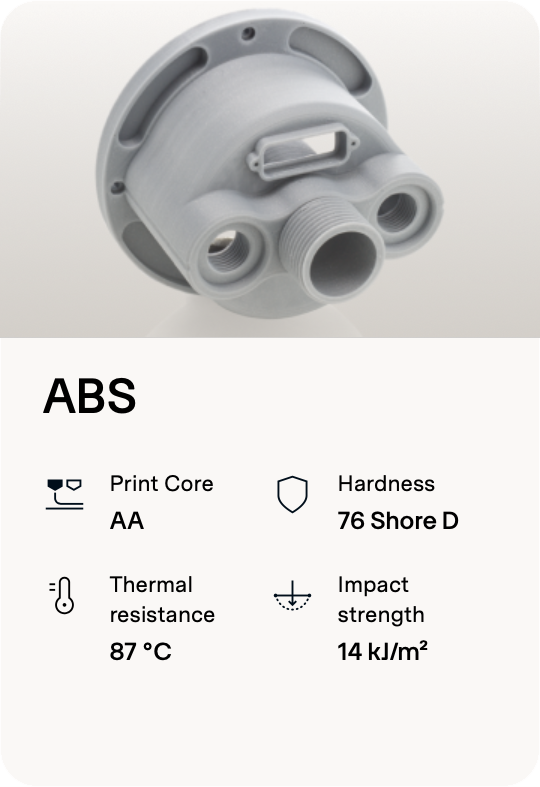

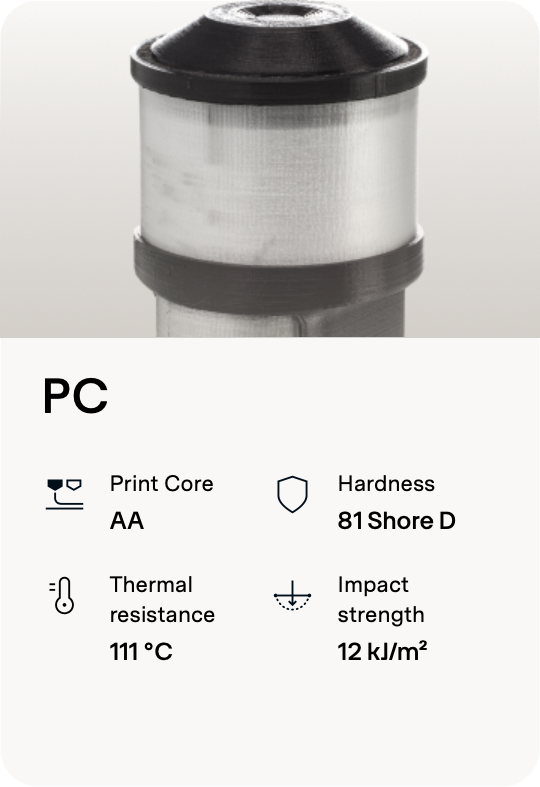

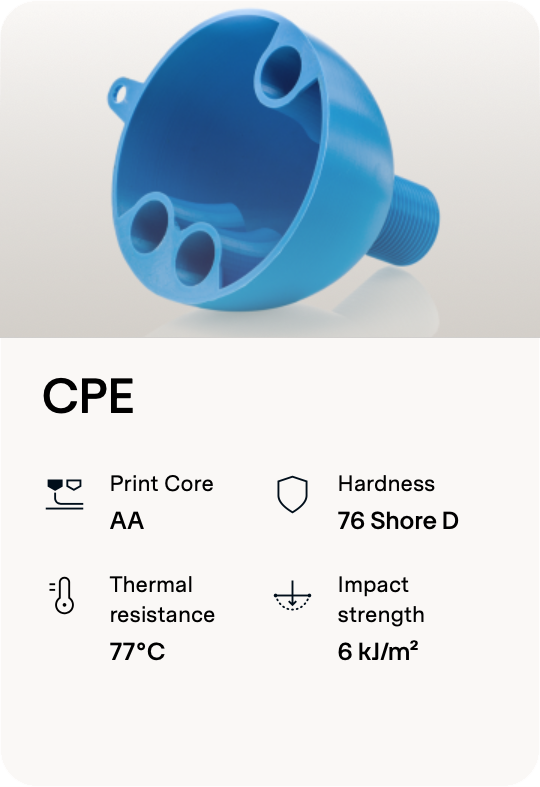

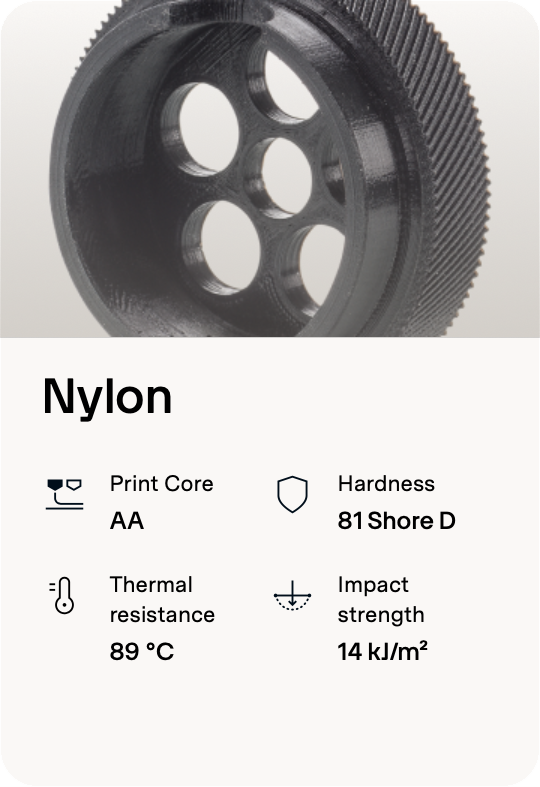

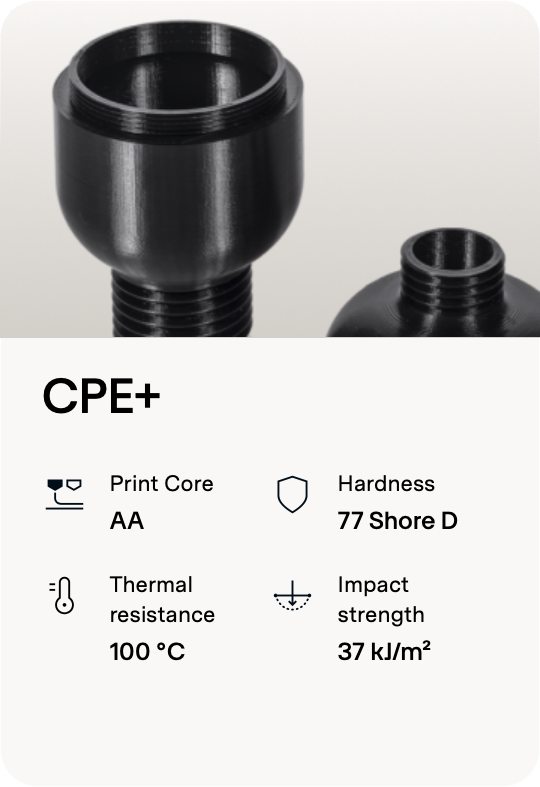

- The extensive selection of high-performance and certified material properties broadens the horizon for a vast array of innovative 3D printing applications on Factor 4, unlocking new possibilities and pushing the boundaries of what's achievable.

- Print with assurance across every millimeter of the expansive 330 x 240 mm flexible build plate on Factor 4, and effortlessly remove finished parts with the assistance of its PEI coating, ensuring a seamless workflow and high-quality results.

- Dimensional accuracy within ±0.2 mm or ±0.2% of the nominal length across the entire printer build volume, employing materials such as PPS CF, PET CF, Tough PLA, and PETG. This ensures precise and reliable printing results, meeting the most demanding standards.

- Unlock the full potential of additive manufacturing with Factor 4's rapid dual printing capabilities, perfect for intricate geometries and multi-material components. This feature empowers you to achieve complex designs with efficiency and precision

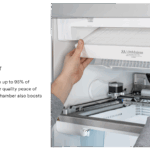

Experience seamless material management with Factor 4's integrated automatic handling system, eliminating the need for manual intervention. With an internal chamber maintained at less than 10% relative humidity in typical office conditions, you can store up to 6 kilograms of filament, ensuring optimal conditions for consecutive print jobs without compromise.

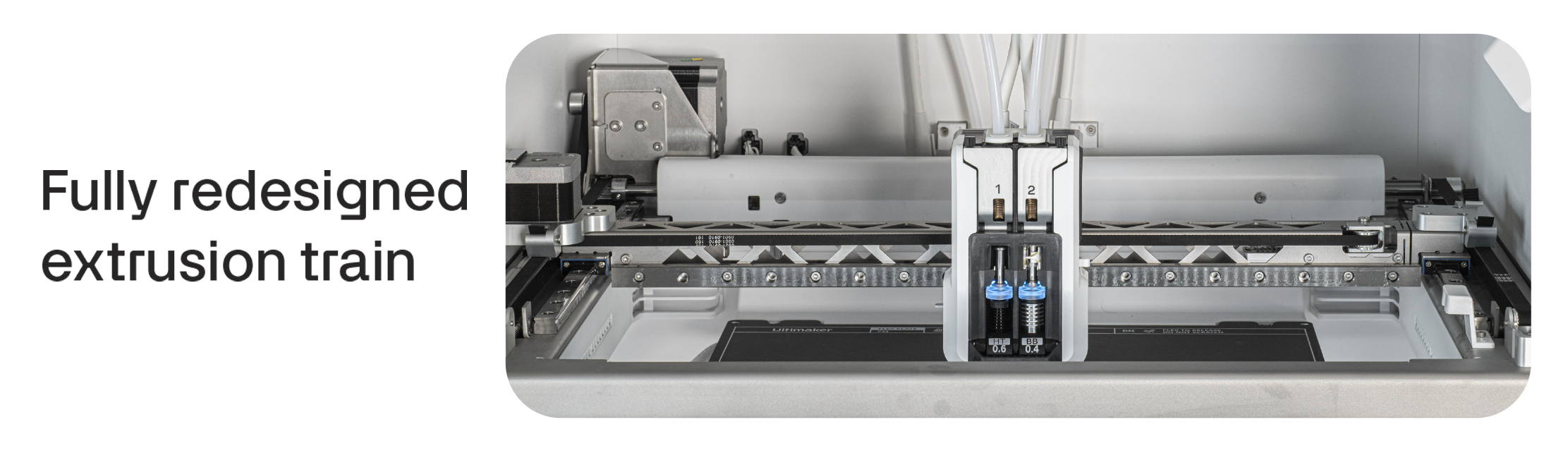

The integration of the innovative H-bridge gantry and direct drive extrusion print head in Factor 4 enables rapid movement and exceptional positional accuracy, with a precision of ±0.2 mm or ±0.2% of the nominal length of features using UltiMaker Verified Materials. This advancement facilitates industry-leading dual material printing speeds, allowd you to swiftly produce the flexible or robust parts you require.

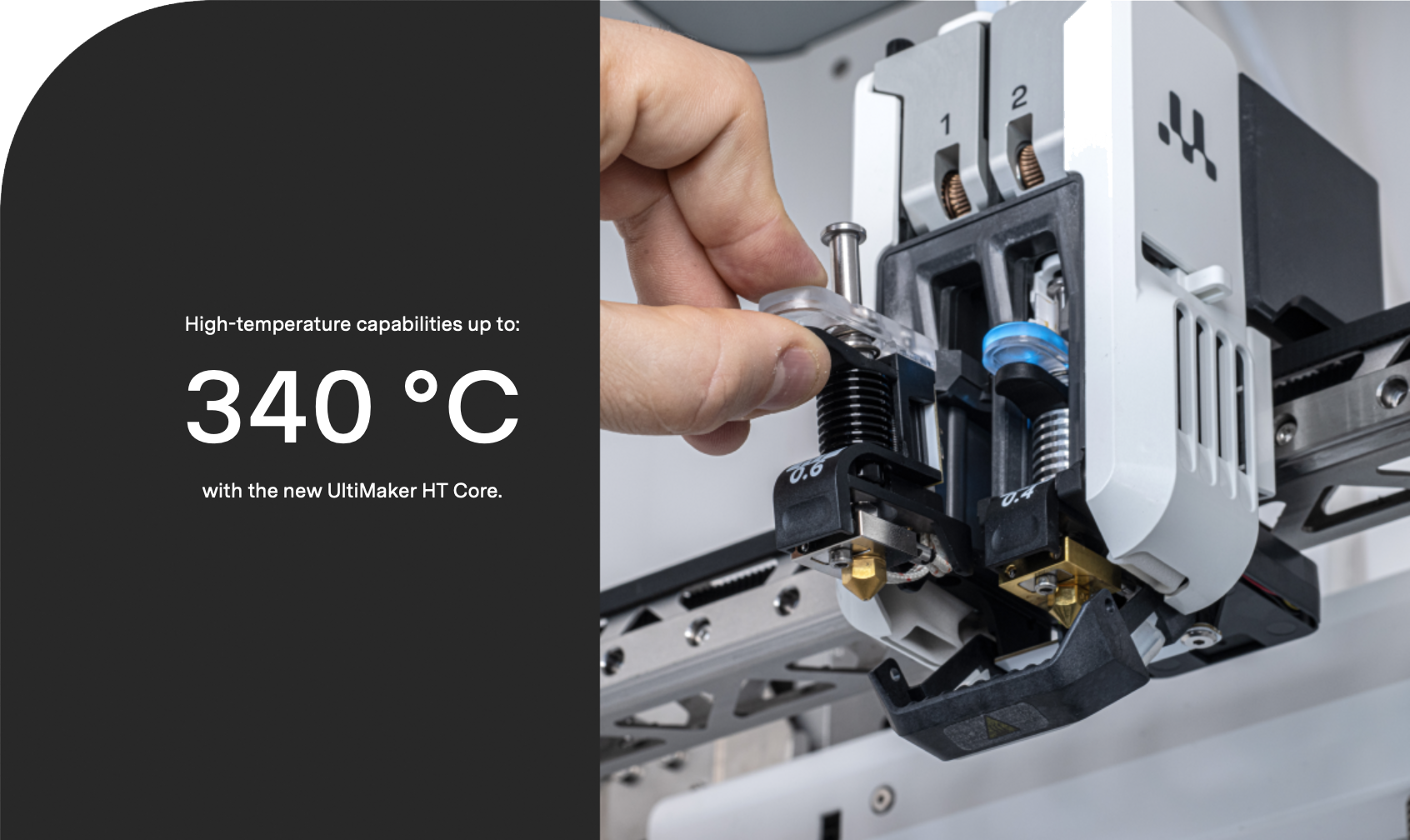

UltiMaker Factor 4 elevates temperatures to 340°C utilizing the HT print core, enabling the printing of high-temperature resistant and durable materials with enhanced confidence.

Within the fully enclosed build volume, temperatures are meticulously controlled, reaching up to 70°C, while the heated bed can achieve temperatures of up to 120°C. These precise temperature controls ensure optimal processing conditions tailored to specific materials, guaranteeing consistent and high-quality part production regardless of the printer's location.

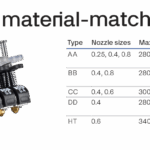

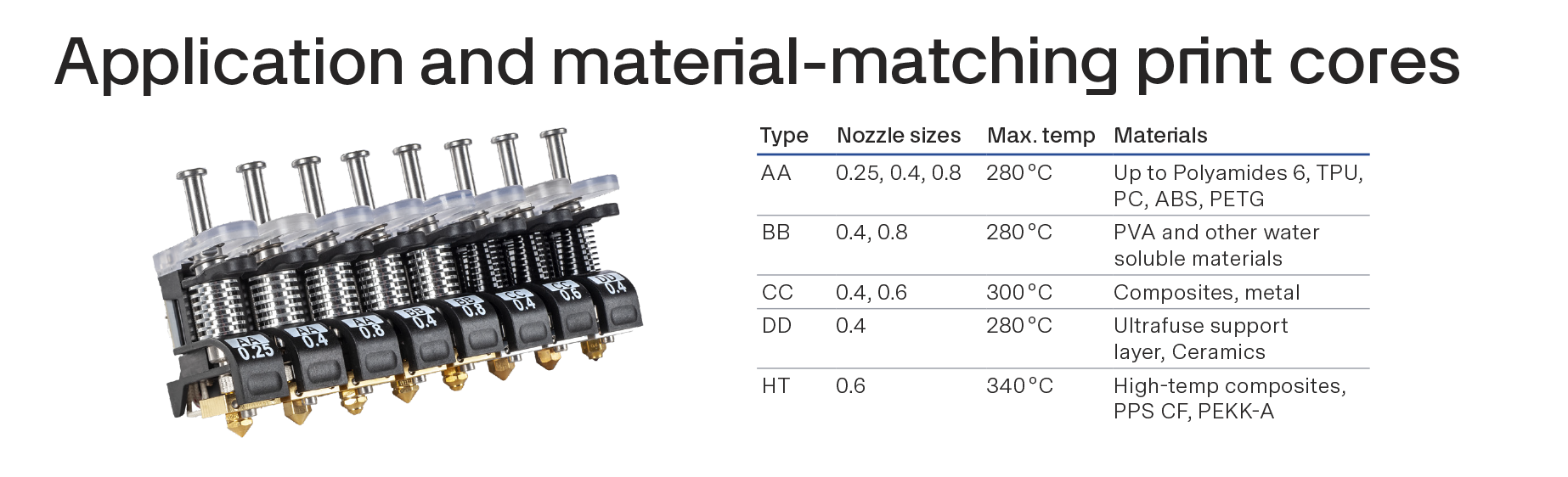

UltiMaker's print cores are engineered with a convenient quick-swap design and integrated EEPROM chip. Seamlessly recognized by Cura, they can be effortlessly interchanged without the need for tools, allowing you to swiftly adapt to the demands of any print job.

Factor 4 demonstrates exceptional versatility by seamlessly transitioning from 3D printing highly flexible materials to robust composites like the innovative UltiMaker PPS-CF. Thanks to its H-bridge gantry and direct drive head, it facilitates rapid dual-material printing. With an impressive high-temperature range of up to 350°C and a heated bed, it ensures consistent quality even with challenging materials. Moreover, its seamless integration with Cura and major AM software platforms enhances workflow efficiency and compatibility.

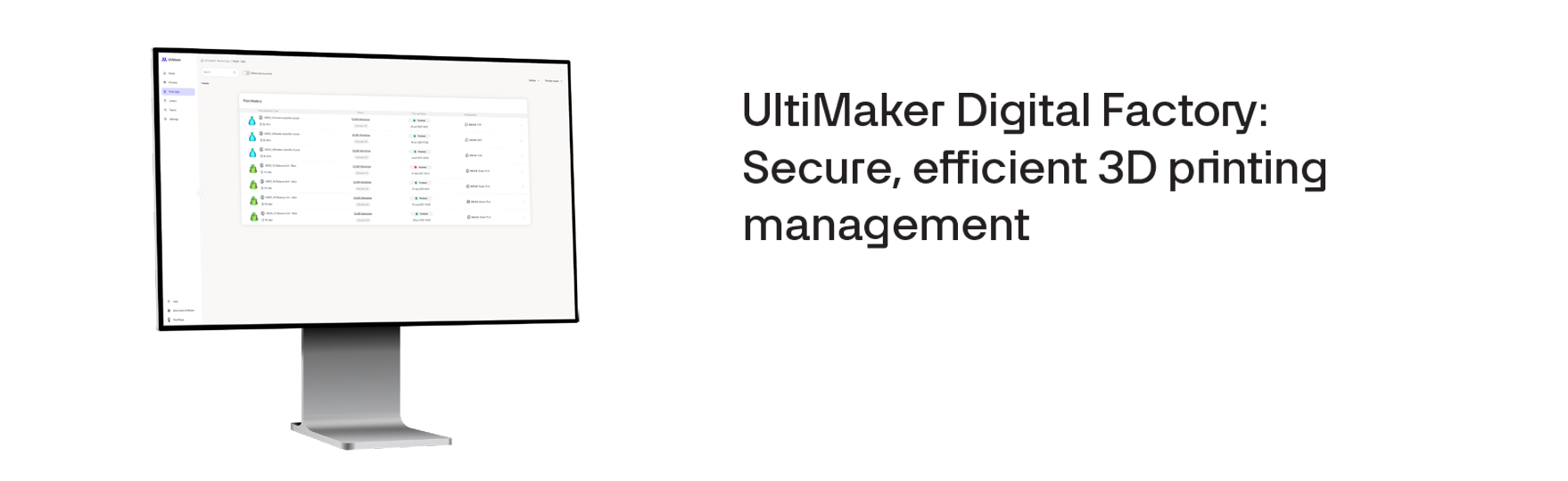

UltiMaker Cura and Digital Factory seamlessly collaborate with Factor 4 and UltiMaker materials, offering a straightforward, secure, and dependable workflow from 3D model to printed part. Stay constantly up-to-date with UltiMaker's commitment to frequent updates. The UltiMaker Factor 4 you invest in today will only improve over the next five years. Equipped with dual onboard processors, it has ample computing power to accommodate both planned and unforeseen future updates, ensuring that your investment continues to evolve and stay at the forefront of innovation.

UltiMaker Cura and Digital Factory seamlessly collaborate with Factor 4 and UltiMaker materials, offering a straightforward, secure, and dependable workflow from 3D model to printed part. Stay constantly up-to-date with UltiMaker's commitment to frequent updates. The UltiMaker Factor 4 you invest in today will only improve over the next five years. Equipped with dual onboard processors, it has ample computing power to accommodate both planned and unforeseen future updates, ensuring that your investment continues to evolve and stay at the forefront of innovation.

Following each print job, you'll receive a comprehensive report detailing any deviations in extrusion parameters from their nominal values, along with their precise locations and severity within the 3D model. Leveraging a suite of sensors strategically placed in the print head, build chamber, and material loading system, this print process reporting functionality serves to verify and validate part quality thoroughly before use in the field.

Tested rigorously to achieve over 95% print completion success and dimensional accuracy within ±0.2 mm or ±0.2% of the feature nominal length, Factor 4 ensures uniform results across multiple machines, making it perfect for generating validated parts for distributed manufacturing.

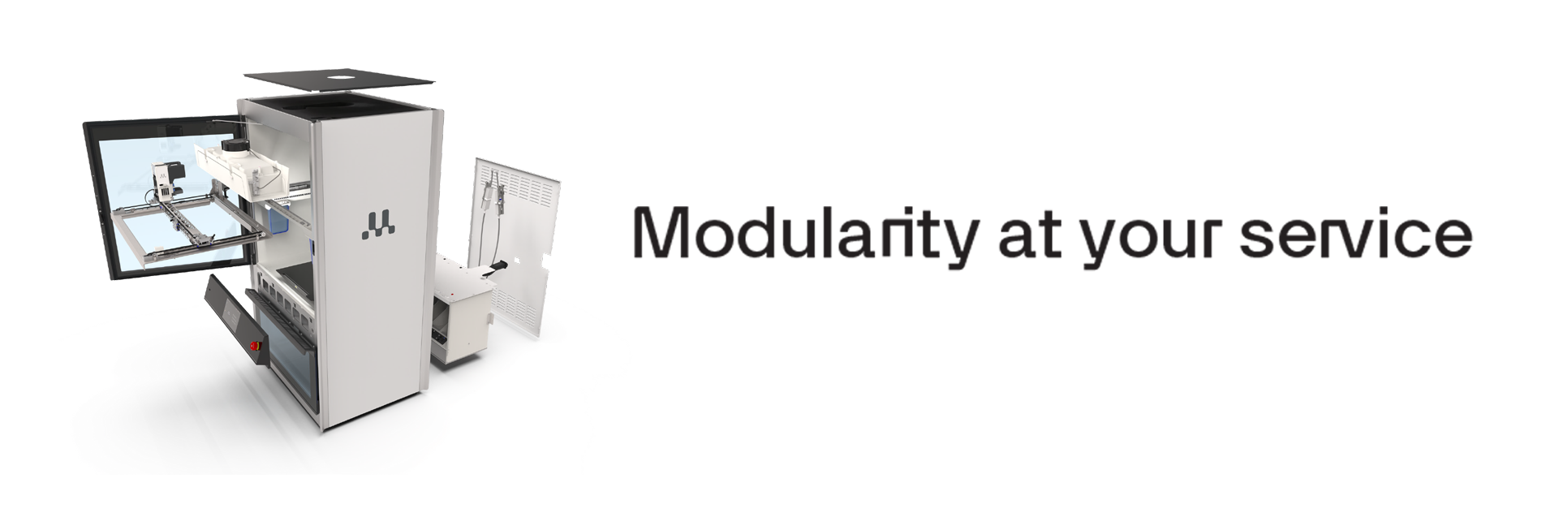

UltiMaker Factor 4 boasts a modular design, ensuring minimal production downtime in the event of servicing requirements. With UltiMaker Factor 4 service plans, skilled technicians can swiftly replace any faulty components, getting your operations back up and running with minimal delay.

UltiMaker Cura stands at the forefront of the additive manufacturing industry, boasting a robust slicing engine that ensures exceptional performance. It supports a wide range of file types, including native CAD files, allowing for swift slicing with pre-configured application intent profiles. Additionally, Cura offers:

- Over 400 settings for precise adjustments

- Material interlocking enabling versatile multi-material combinations

- Sequential printing, tailored for small-batch production

- Regular updates that continuously enhance the printing experience

Streamline your printing schedule coordination effortlessly with shared workspaces, assigned roles, and file management through the digital library. Each Factor 4 printer features a live HD camera feed, accompanied by progress and status updates, simplifying the management of multiple prints across multiple printers without downtime. Additionally, Digital Factory offers:

- Detailed analytics for review and forecasting, with the option for CSV export

- A comprehensive overview and history of printer maintenance tasks

- Secure remote control capabilities for reprinting jobs without the need for reslicing.

INCREASED EASE OF USE:

- Easy and safe access to printer rear side for maintenance and repair

- Safe displacement and transport

- Minimal floor occupancy

BUILT-IN SAFETY:

- Tailor-made for Factor 4

- Anti-tilting architecture and stability tailored for Factor 4

- Lock in mechanisms to fix printer to cabinet

ERGONOMICALLY DESIGNED:

- Perform operations at right height and comfort

- Store 18 spools and accessories with lockable drawers